Lord Fin Tube-Low Finned Tubes|Low fin tubes

What are Low Finned Tubes?

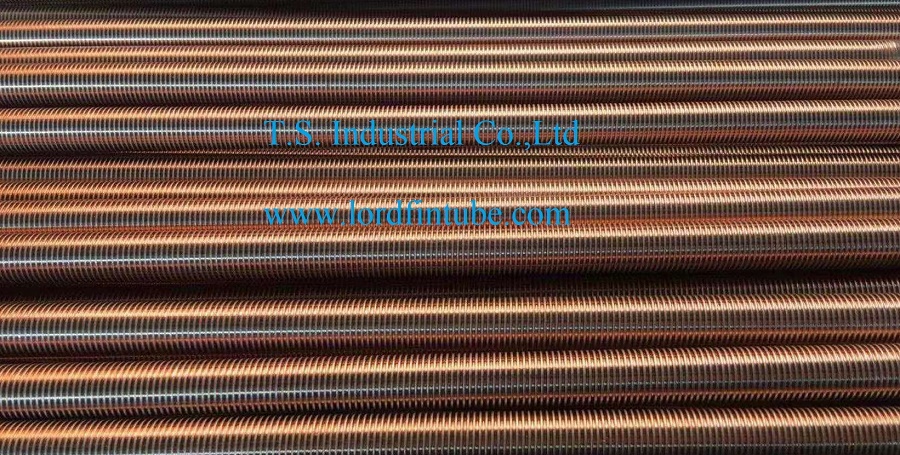

Low Finned Tubes are a type of heat exchanger component created by rotating the outer surface of steel tubes to form fins. Typically, these tubes are designed with each fin extending approximately 25.4 millimeters (1 inch) along the length of the steel pipe, with commonly 19 fins per tube. However, variations with 26 fins are also possible. This rotational process significantly increases the outer surface area of the tube, making it approximately 3.5 times larger than the inner surface area. This increased surface area enhances heat transfer efficiency, leading to various benefits such as increased capacity, weight reduction, reduced material and shipping costs, as well as optimized space utilization.

Unlike high fin tubes, which involve welding peripheral fins onto steel pipes, low finned tubes are processed by directly rotating the steel pipes. This method eliminates the risk of fin detachment, ensuring excellent durability and anti-vibration properties even under bending conditions.

Low-finned tubes find applications across various industries including:

- Power plants (nuclear, electric, thermal, and geothermal)

- Petrochemical and chemical industries

- Highly corrosive systems such as evaporators and condensers

- Food processing and refrigeration industries

These tubes are commonly machined to precise specifications, including fin height, fin distance, and fin thickness, to meet specific heat transfer requirements. Due to their efficient heat transfer capabilities, they are frequently used in air conditioner condensers and evaporator heat exchange elements.

Low finned tubes offer several advantages, including excellent anti-fouling performance. The unique accordion-like expansion and contraction during operation hinder the formation of dirt, as debris tends to form parallel flakes along the edge of the fins. This feature helps maintain optimal heat transfer efficiency over extended operational periods.

Standards and materials for low finned tubes

Low Fin Tube Standards:

1. ASTM Standards: ASTM A179/A179M (for seamless cold-drawn low-carbon steel heat exchanger and condenser tubes), ASTM A213/A213M (for seamless alloy steel, stainless steel, and nickel alloy tubes), ASTM A312/A312M (for seamless and welded stainless steel tubes), etc.

2. ASME Standards: ASME SA179 (for seamless cold-drawn low-carbon steel heat exchanger and condenser tubes), ASME SA213 (for seamless alloy steel and stainless steel tubes), ASME B36.10 (for dimensions and marking of welded and seamless steel pipes), etc.

3. DIN Standards: DIN 17175 (for seamless steel tubes, alloy steel, and stainless steel tubes), DIN 2391 (for cold-drawn precision steel tubes), DIN 2462 (for stainless steel seamless tubes), etc.

Low Fin Tube Materials:

1. Carbon Steel: Common carbon steel materials include ASTM A179, ASTM A192, ASTM A210, etc., used for low and medium temperature heat exchangers and boiler pipelines.

2. Stainless Steel: Stainless steel materials include ASTM A213 TP304, ASTM A213 TP316, etc., commonly used for applications requiring corrosion resistance, such as chemical, and food processing industries.

3. Alloy Steel: Alloy steel materials include ASTM A213 TP5, ASTM A213 TP9, etc., with excellent high-temperature and pressure resistance, commonly used in high-temperature and high-pressure environments such as power plants.

4. Copper Alloys: Copper alloy materials such as C71500 (copper-nickel alloy) and C70600 (copper-nickel-zinc alloy) are commonly used for applications requiring high thermal conductivity, such as air conditioners and condensers.

These standards and materials are typically applicable to the manufacturing and application of various heat exchangers and boiler pipelines. Depending on specific engineering requirements and application environments, different standards and materials may be chosen to meet performance and durability requirements.