The difference between high fin tube and low fin tube?

Whats the difference between high fin tube and low fin tube?

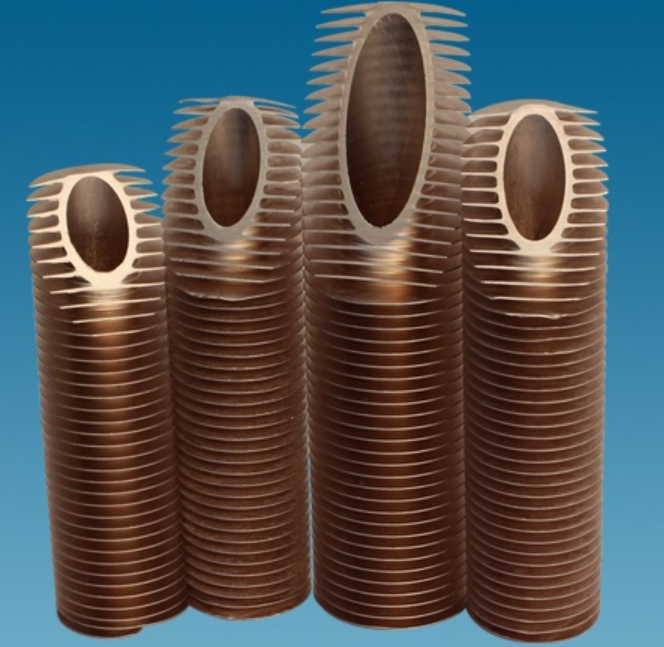

High fin tube and low fin tube are types of heat exchanger tubes that are designed with different fins to increase their heat transfer efficiency. The main difference between high fin tube and low fin tube is in the height and density of the fins:

High fin tube: This type of tube has fins that are relatively tall and widely spaced apart. The fins typically have a height of 0.625 to 0.75 inches and a fin density of 7 to 11 fins per inch. The high fins provide a greater surface area for heat transfer, which makes them more effective in applications where the temperature difference between the two fluids is high.

Low fin tube: In contrast, low fin tubes have shorter fins that are closely spaced together. The fins typically have a height of 0.125 to 0.25 inches and a fin density of 16 to 26 fins per inch. The low fins are more effective in applications where the temperature difference between the two fluids is low.

In summary, high fin tubes are suitable for applications where the temperature difference between the two fluids is high, while low fin tubes are better for applications where the temperature difference is low. The choice of which type of tube to use depends on the specific requirements of the application.

Will the high fin tube and low fin tube use different material?

High fin tubes and low fin tubes can be made from the same or different materials depending on the specific application requirements. In many cases, the choice of material for high fin tubes and low fin tubes is based on factors such as heat transfer requirements, corrosion resistance, mechanical strength, and cost.

For example, a high fin tube and low fin tube used in the same heat exchanger may be made from the same material, such as copper or stainless steel, but have different fin geometries to achieve different heat transfer performance. However, in some applications, different materials may be chosen for high fin tubes and low fin tubes to optimize their performance. For instance, a low fin tube used in a power plant may be made from carbon steel due to its cost-effectiveness, while a high fin tube used in a refrigeration system may be made from copper due to its high thermal conductivity.

In summary, the choice of material for high fin tubes and low fin tubes depends on the specific application requirements, and it is possible for them to be made from the same or different materials.