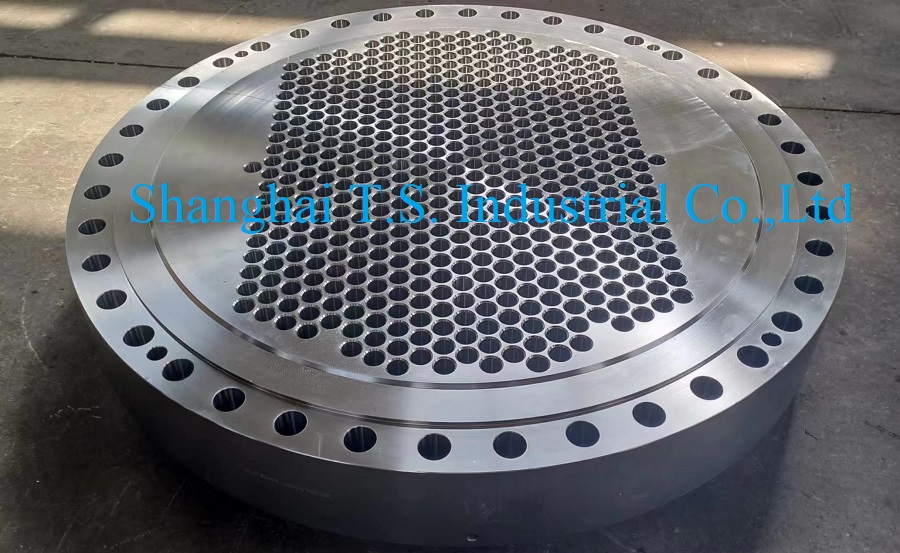

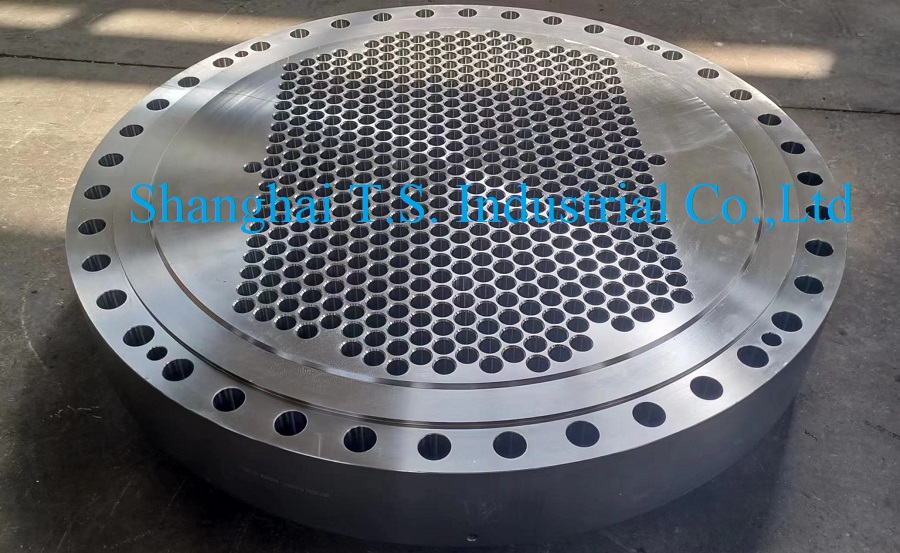

Products Description

High-pressure forged stainless steel tube sheets are a critical component widely used in the industrial sector, known for their exceptional strength and corrosion resistance, making them suitable for various applications in high-temperature, high-pressure, and corrosive environments.

1. High-Pressure Forged Stainless Steel Tube Sheets Material Characteristics:

- Stainless Steel: Typically, materials like F316 or F304 stainless steel are used, renowned for their excellent corrosion resistance and strength, making them apt for various challenging conditions.

- High-Pressure Forging: This process involves the plastic deformation of the material under high temperature and pressure, ensuring a uniform internal structure, enhancing strength and durability.

2. High-Pressure Forged Stainless Steel Tube Sheets Manufacturing Process:

- Material Preparation: The right stainless steel billet is chosen, ensuring its quality and dimensions align with the design requirements.

- Billet Cutting: Through cutting techniques, the billet is shaped and sized according to design specifications.

- Preheating: Before forging, the billet undergoes preheating to enhance its malleability and reduce the risk of cold cracking.

- Forging: Using conditions of high temperature and pressure, the billet is molded into the desired tube sheet shape through several strikes or compression steps.

- Hole Processing: After forging, holes are machined to facilitate the installation of tube bundles or pipes.

- Heat Treatment (if required): Depending on specific needs, the material undergoes heat treatment to optimize its properties.

- Inspection and Testing: Rigorous quality checks and tests are executed to ensure the products quality and compliance.

- Final Processing: Based on project specifications, finishing processes, including surface treatments, anti-corrosion coatings, and markings, are done.

- Delivery: Upon completing all processes, the tube sheet is ready for delivery to the client or for assembly into equipment.

3. High-Pressure Forged Stainless Steel Tube Sheets Applications:

- High-pressure forged stainless steel tube sheets are widely used in sectors like chemicals, petroleum, energy, and food for components of pressure vessels, heat exchangers, reactors, etc.

- Due to their strength and corrosion resistance, they can withstand high temperatures, pressures, and corrosive agents, ensuring the safe operation of equipment.

In summary, high-pressure forged stainless steel tube sheets are quintessential engineering materials. Their fabrication process undergoes stringent quality controls and compliance checks to deliver products with exceptional performance, durability, and safety. Their broad applicability in the industrial realm offers reliable solutions for equipment operating under high pressure, temperature, and corrosive conditions.