Products Description

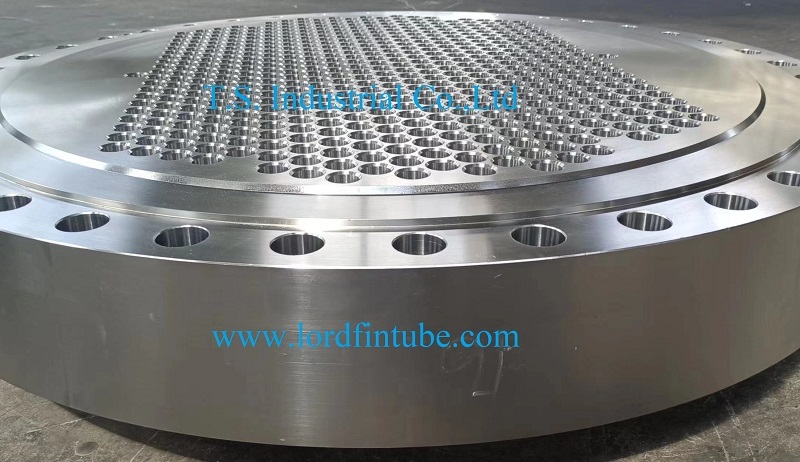

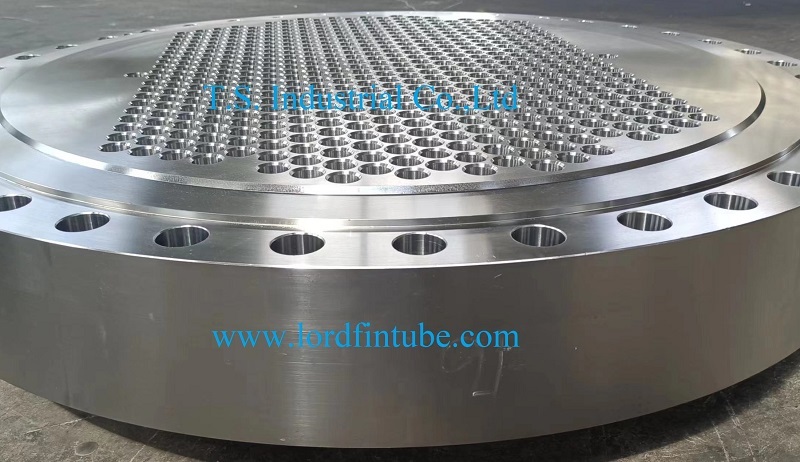

What is floating tube sheet?

A floating tube sheet is a component used in shell-and-tube heat exchangers, a type of heat exchanger widely employed in various industrial applications. In a shell-and-tube heat exchanger, a bundle of tubes is housed within a cylindrical shell. One end of the tubes is fixed or attached to a tube sheet, while the other end is allowed to float or move within the tube sheet. This floating arrangement accommodates differential thermal expansion between the tubes and the shell.

Floating Tube Sheet Main Material Grade:

The material used for floating tube sheets depends on the specific requirements of the application, including factors such as temperature, pressure, and the nature of the fluids involved. Common materials for tube sheets in heat exchangers include various grades of stainless steel, carbon steel, and non-ferrous alloys like brass or copper-nickel. For critical applications, materials may be selected based on their corrosion resistance, thermal conductivity, and mechanical properties.

Floating Tube Sheet Common Thickness:

The thickness of the tube sheet also depends on the specific design and operating conditions of the heat exchanger. Tube sheets are typically thick enough to provide the required strength and support for the tubes, taking into account factors such as pressure, temperature, and mechanical loads. Common thicknesses can range from a few millimeters to several centimeters.

Floating Tube Sheet Applications:

Floating tube sheets are used in shell-and-tube heat exchangers, which find applications in a wide range of industries, including:

1. Petrochemical Industry: For cooling and condensing processes in refineries and petrochemical plants.

2. Power Generation: In power plants for condensers and heat recovery steam generators (HRSG).

3. Chemical Processing: Used in various chemical processes for heating or cooling fluids.

4. HVAC Systems: In large-scale air conditioning and heating systems.

5. Food and Beverage Industry: In applications such as pasteurization and sterilization.

The floating tube sheet design is particularly important in applications where there are significant temperature variations, and differential thermal expansion between the tubes and the shell needs to be accommodated to prevent damage and maintain the integrity of the heat exchanger over time.