How is the integral fin tube processed? What are its advantages?

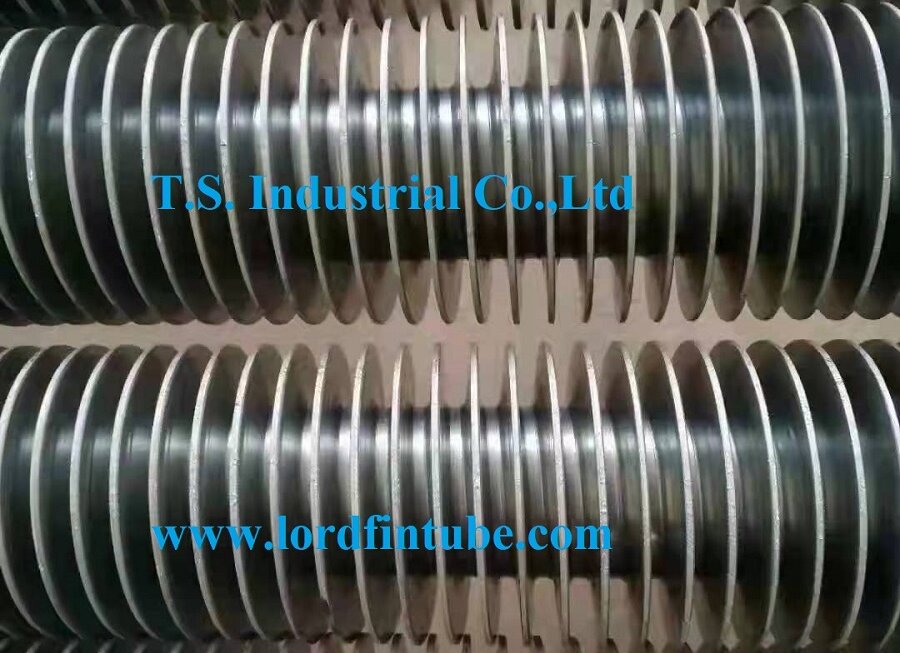

Integral spiral finned tubes are produced by continuously heating seamless thick-walled base tubes using medium-frequency induction, then subjecting them to a single-pass forming process involving extrusion and rolling. The fins and base tube form an integral, homogeneous structure of the same material without any welding.

The process primarily involves three spiral rolling shafts rotating synchronously on fixed axes. Driven by friction, these shafts impart both rotational and axial movement to the workpiece.

Material: Alloy Steel & Carbon Steel

Base Tube:

ID: 22-66 mm

WT: 2-9 mm

Length: 1500-12000 mm

Fin Pitch: 3-15 mm

Fin Height: 4-15 mm

Fin Thickness at top: 1-4 mm

Dimension Tolerance of Integral Finned Tube (mm)

|

Base Tube |

Fin |

||||||

|

O.D. |

I.D. |

W.T. |

L |

Height |

Thickness |

Pitch |

|

|

2-4mm |

5-9mm |

||||||

|

±0.50 |

±0.50 |

±0.45 |

+10% -8% |

+20 -10 |

+1.5 -1.0 |

±0.35 |

±0.50 |

Straightness: Deflection ≤ 2 mm per meter

Dimensions of Integral Spiral Finned Tube

|

Base Tube |

Fin |

|||

|

OD (mm) |

ID (mm) |

WT (mm) |

Height (mm) |

Pitch (mm) |

|

25 |

20 |

2.5 |

6-8 |

6 |

|

32 |

26 |

3 |

10-12 |

8 |

|

32 |

26 |

3 |

10-12 |

10 |

|

38 |

30 |

4 |

10-12 |

8 |

|

38 |

30 |

4 |

10-12 |

10 |

|

42 |

34 |

4 |

10-12 |

8 |

|

42 |

34 |

4 |

10-12 |

10 |

|

48 |

40 |

4 |

10-12 |

8 |

|

48 |

40 |

4 |

10-12 |

10 |

|

51 |

43 |

4 |

10-12 |

8 |

|

51 |

43 |

4 |

10-12 |

10 |

|

51 |

43 |

4 |

10-12 |

10 |

Performance Comparison for Tubes with Identical Diameter and Wall Thickness

|

Performance |

Bare Tube |

Integral Spiral Finned Tube |

|

|

Fin-to-Tube Bonding |

Without fins |

High-frequency welding |

Monolithic structure, hot-rolled, weld-free |

|

Heat Transfer Area |

Small |

Large |

Large |

|

|

4 times area per unit length more than bare tube |

4 times area per unit length more than bare tube |

|

|

Heat Transfer Coefficient |

Low |

High 2 times more than bare tube |

Higher 3 times more than bare tube |

|

Flue gas-side heat transfer dominates. Equal inner/outer surface area causes heat loss before full transfer. |

Contact thermal resistance causes unstable heat transfer. Long-term use risks weld cracking. |

1.Zero contact thermal resistance |

|

|

Ash Fouling |

Prone to fouling |

Less prone to fouling |

Highly resistant to fouling |

|

Ash accumulates on tube leeward side. Ash layer conductivity is extremely low – 1mm ash. Fouling resistance reduces heat transfer and raises tube wall temperature, risking overheating/failure. |

1. Fins act as flow guides, creating Karman vortices for self-cleaning |

1. Smooth radius transition at fin root |

|

|

Compressive Strength |

As per boiler tube standards |

Slightly higher |

Because the fins are integrated with the mother tube and form a spiral belt, the compressive strength is significantly increased by nearly 3 times compared to the bare tube. |

|

Abrasion Resistance |

Low |

Improved |

Significantly improved |

|

High-velocity ash erodes tube walls, causing thinning /rupture |

Fins reinforce tube and shield against direct impact |

Hot rolling increases metal density/hardness. Enhanced hardness (especially at fin tips) resists ash erosion, solving severe wear in CFB boilers. |

|

|

Service Life |

Short (2-3 years, requires overhaul/replacement) |

Moderately longer |

Significantly extended |

Hydrostatic Test

Test pressure is calculated per the following formula, with a maximum test pressure of 20 MPa. Pressure must be maintained for no less than 10 seconds. No leakage shall occur under test pressure.

P=2δxR/D0

P —— Test pressure, MPa

δ—— Nominal wall thickness of steel tube, mm

D0 —— Root diameter of fins, mm

R —— Allowable stress, MPa

Main Advantages of Integral Finned Tube

Extended Service Life: Over 3 times longer than wound welded finned tubes.

Cleanability: Smooth arc transition at the fin root and polished fin surface completely eliminate ash accumulation, blockage, and slagging issues common in other fin types where root folding occurs.

Enhanced Material Properties: Hot roll forming increases material density, yield strength, tensile strength, and wear resistance.

Superior Pressure Resistance: The integral spiral fin structure withstands over 3 times the pressure capacity of seamless tubes with equivalent wall thickness and ID.

Good Abrasion Resistance: Effectively addresses severe wear in coal-fired boiler convection sections caused by high flue gas velocity and ash concentration (particularly in Circulating Fluidized Bed Boilers).

High Heat Transfer Efficiency: The monolithic structure removes interfacial thermal resistance inherent in bonded fin designs, while the trapezoidal fin cross-section maximizes heat transfer efficiency.

Stable Performance: The integral construction prevents fin loosening or detachment under high-temperature and harsh conditions, ensuring stable thermal performance.