What are HRSG (Heat Recovery Steam Generator) finned pipes?

What are HRSG (Heat Recovery Steam Generator) finned pipes?

HRSG (Heat Recovery Steam Generator) finned pipes are a specific type of heat transfer fin tubes used in HRSG units. HRSGs are widely used in power plants to recover waste heat from the exhaust gases of gas turbines and utilize it to generate steam, which can then be used for various purposes, such as power generation or process heating.

The finned pipes in an HRSG serve the purpose of enhancing heat transfer efficiency between the hot flue gases and the water/steam inside the pipes. The fins are typically attached to the outer surface of the pipes, increasing the surface area available for heat exchange and improving the overall thermal performance of the HRSG.

Features and advantages of HRSG finned pipes:

1. Extended surface area: The fins on the pipes significantly increase the surface area available for heat transfer, allowing for more efficient heat exchange between the hot flue gases and the fluid inside the pipes.

2. Enhanced heat transfer efficiency: The extended surface area provided by the fins promotes better heat transfer, enabling the recovery of a larger amount of waste heat from the exhaust gases.

3. Improved steam generation: The increased heat transfer efficiency of HRSG finned pipes results in higher steam generation rates, which can lead to improved power plant performance and energy efficiency.

4. Compact design: Finned pipes offer a compact solution for heat transfer, allowing for a more space-efficient design of the HRSG unit.

5. Temperature uniformity: The use of finned pipes helps to distribute heat more evenly along the pipe length, promoting uniform temperature distribution and reducing the risk of thermal stress or hot spots.

HRSG finned pipes are critical components in HRSG units, as they enable the effective recovery and utilization of waste heat, improving overall energy efficiency in power generation. They are designed to withstand the high-temperature and corrosive environments typically encountered in HRSG applications.

Finned pipe and material in an HRSG

The choice of finned pipe and material in an HRSG (Heat Recovery Steam Generator) depends on various factors such as operating conditions, performance requirements, flue gas composition, and budget considerations. Here are some common types of finned pipes and materials used in HRSGs:

1. Carbon Steel Finned Pipes: Plain carbon steel finned pipes are often used in HRSGs due to their cost-effectiveness and adequate corrosion resistance in moderate operating conditions. They are suitable for applications where the flue gas temperature and corrosive environment are within acceptable limits.

2. Stainless Steel Finned Pipes: Stainless steel finned pipes offer better corrosion resistance than plain carbon steel, making them suitable for HRSGs operating in more aggressive or high-temperature environments. Stainless steel grades like 304 and 316 are commonly used due to their excellent corrosion resistance properties.

3. Alloy Steel Finned Pipes: Alloy steel finned pipes are employed in HRSGs that operate under high-temperature and high-pressure conditions. These alloys provide superior mechanical strength, creep resistance, and corrosion resistance compared to carbon steel, enabling them to withstand more severe operating conditions.

4. Inconel Finned Pipes: Inconel is a family of nickel-chromium-based alloys known for their exceptional resistance to high temperatures, oxidation, and corrosion. Inconel finned pipes are used in HRSGs operating at extremely high temperatures or in highly corrosive environments.

Regarding HRSG choice of finned types:

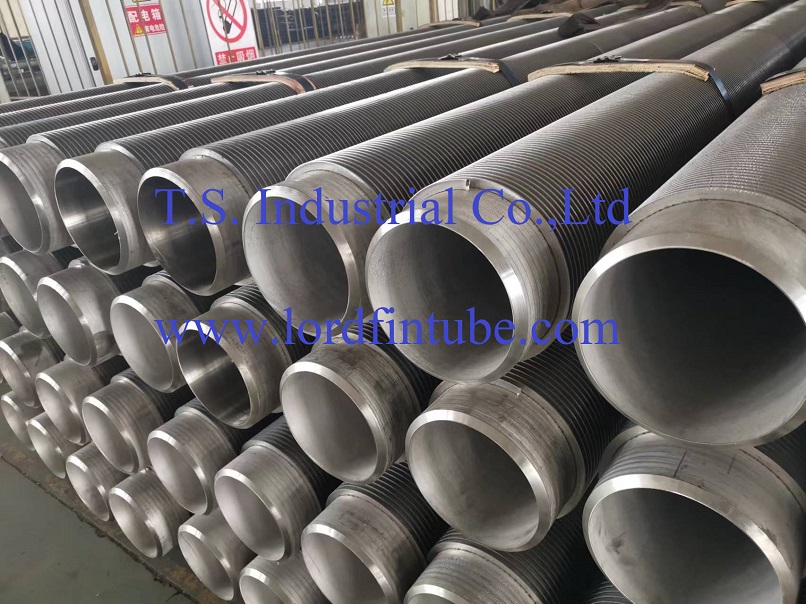

a. Solid Finned Pipes: Solid or extruded finned pipes have fins that are mechanically bonded or extruded onto the outer surface of the pipe. These fins provide a large surface area for heat transfer and are suitable for HRSG applications requiring efficient heat exchange.

b. Serrated Finned Pipes: Serrated finned pipes have fins with serrated edges, which increase turbulence and promote better heat transfer. They are commonly used in HRSGs where higher heat transfer coefficients are required.

c. Laser Welded Finned Pipes: Laser welded finned pipes have relatively shorter and denser fins compared to other types. They are effective in increasing the heat transfer surface area while maintaining a low pressure drop. Low finned pipes are often used in HRSGs with limited space or where pressure drop is a concern.

The selection of the specific finned pipe and material combination for an HRSG should be based on a thorough understanding of the operating conditions, performance requirements, and potential corrosion risks in order to ensure optimal performance and longevity of the system. Consulting with HRSG manufacturers or heat transfer experts can provide further guidance based on the specific project requirements.