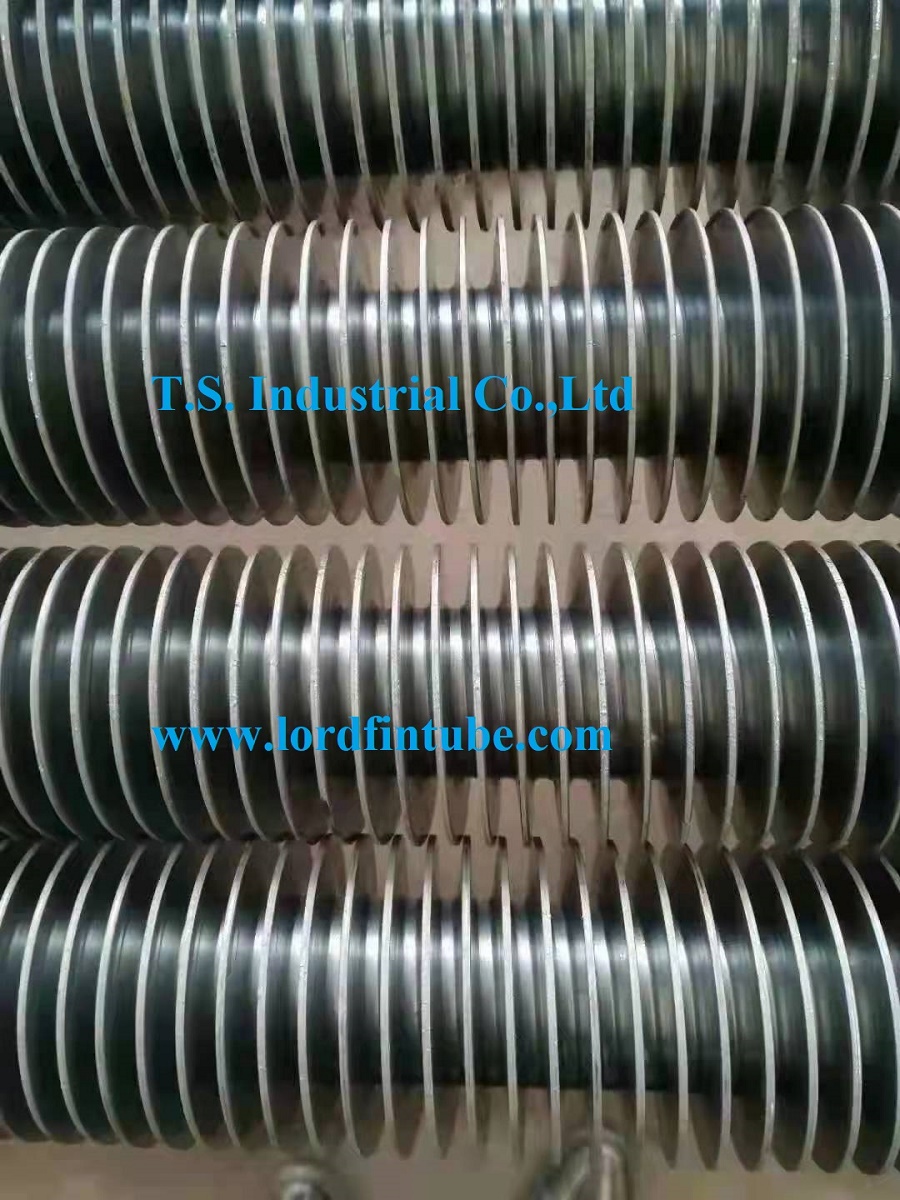

Lord Fin Tube-Integral spiral finned tube

Advantages of Integral Spiral Finned Tube

The integral spiral finned tube is widely used in power plant boilers, waste heat recovery systems, building heating, and various industrial applications due to its exceptional weldability and thermal performance.

With high heat transfer efficiency, extensive heat dissipation area, and the ability to withstand higher pressures, these tubes offer superior performance and longer service life compared to conventional alternatives.

Advantages of Integral Spiral Finned Tube

-

Excellent Overall Heat Transfer Efficiency

The overall heat transfer efficiency of the integral spiral finned tube is outstanding. When compared with other finned tube products, its heat transfer efficiency is significantly higher. Compared with bare tubes, its heat transfer efficiency is approximately four times higher.

-

Integral Construction with Minimal Thermal Resistance

For the integral spiral finned tube, the entire fin is rolled integrally with the base tube as a single unit. In contrast, ordinary finned tubes have fins directly welded onto the surface of the base tube. This welding joint surface is prone to thermal resistance, which seriously affects heat transfer efficiency.

-

Superior Anti-Ash Deposition Capability

The integral spiral finned tube performs better than ordinary finned tubes in resisting ash deposition. Thanks to its high-quality performance characteristics, its operational effectiveness has been significantly improved.

-

Enhanced Corrosion Resistance

Since the integral spiral finned tube is manufactured through multi-roll rolling, its surface smoothness is relatively high, and the overall organizational density is also very high. The transition between the fin and the base tube is natural, resulting in significantly improved anti-corrosion performance.

Technical Specifications

Integral Spiral Finned Tube Application

In addition to the industries mentioned above, integral spiral finned tubes also excel in the following applications:

Integral Spiral Finned Tube Technical Features

Higher Thermal Efficiency

Significantly reduces energy consumption through improved heat transfer capabilities.

Compact Design

Space-saving configuration ideal for applications with limited installation space.

Extended Service Life

Longer operational lifespan reduces maintenance costs and downtime.

Wide Application Range

Suitable for diverse industrial applications across multiple sectors.

Superior Corrosion Resistance

Enhanced durability in challenging operational environments.

High Pressure Resistance

Capable of withstanding demanding operational conditions.

Integral Spiral Finned Tube

The integral spiral finned tube represents a significant advancement in heat transfer technology. Its integral construction, superior heat transfer efficiency, and enhanced durability make it an ideal choice for various industrial applications where efficient heat exchange is critical.

The combination of these advantages results in improved system performance, reduced operational costs, and longer equipment lifespan. As industries continue to seek more efficient and reliable heat exchange solutions, the integral spiral finned tube stands out as a superior option that delivers measurable benefits across multiple performance metrics.