Lord Fin Tube-KLM Finned Tubes

What are KLM Finned tubes?

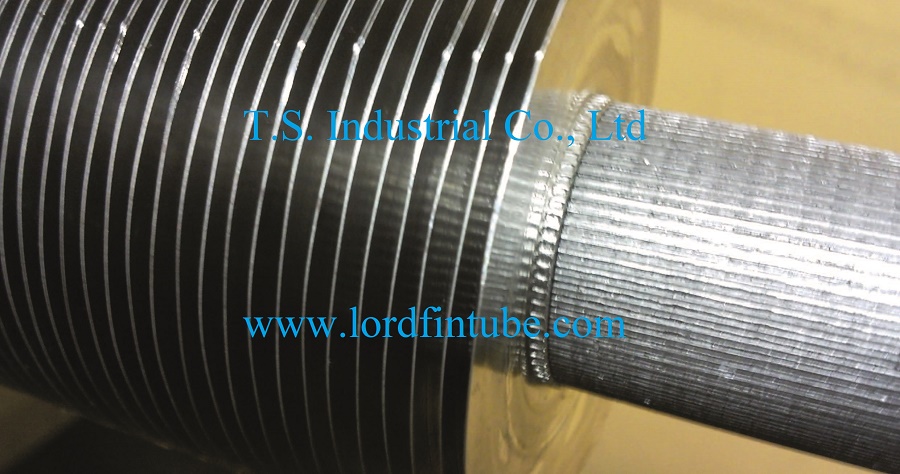

The base tube outer surface is additionally knurled before wrapped the L shaped fin strip, which ensures better contact. After wrapped the fin strip, the fin foot is also knurled on the base tube to increase the bonding between tube and fin. KLM finned tubes are heat transfer devices used in various industries to enhance heat exchange efficiency. They consist of a base tube with fins attached to the outer surface. The fins increase the surface area of the tube, allowing for improved heat transfer between the fluid inside the tube and the surrounding environment.

Applications of KLM Finned Tubes:

1. Heat exchangers: KLM finned tubes are commonly used in heat exchangers for applications such as air conditioning, refrigeration, power plants, and chemical processes. They enable efficient heat transfer between fluids of different temperatures.

2. Boilers: Finned tubes are employed in boilers to optimize heat transfer from the hot gases to the water or steam.

3. Condensers: KLM finned tubes are utilized in condensers to enhance the heat transfer from the vapor to the cooling medium, facilitating condensation.

4. Radiators: They are used in radiators of automobiles, where the fins help dissipate heat efficiently.

5. Oil coolers: Finned tubes are employed in oil coolers to cool down oil in applications such as hydraulic systems and lubrication systems.

Manufacturing Process of KLM Finned Tubes:

The manufacturing process of KLM finned tubes typically involves the following steps:

1. Tube preparation: A base tube is selected based on the specific requirements of the application, considering factors such as material, size, and thermal conductivity.

2. Fin attachment: Fins are usually made from a separate material, such as aluminum or copper. These fins are then attached to the outer surface of the base tube using various methods, including extrusion, high-frequency welding, or laser welding. The finning process creates a strong bond between the tube and the fins.

3. Fin formation: The fins can have different configurations, such as plain, helical, or serrated. The desired fin shape is achieved through processes like rolling, stamping, or cutting.

4. Surface treatment: The finned tubes may undergo surface treatments like coating or painting to provide corrosion resistance or improve heat transfer properties.

Advantages of KLM Finned Tubes:

1. Enhanced heat transfer: The main advantage of KLM finned tubes is their ability to increase the surface area available for heat transfer. This results in improved heat exchange efficiency and allows for the transfer of higher heat loads.

2. Compact design: The use of finned tubes allows for the design of compact heat exchangers, which are advantageous in applications where space is limited.

3. Temperature control: KLM finned tubes provide better temperature control by facilitating efficient heat transfer, ensuring that the desired temperature is maintained.

4. Energy efficiency: By maximizing heat transfer efficiency, KLM finned tubes help reduce energy consumption in various thermal processes, resulting in cost savings.

5. Versatility: KLM finned tubes can be manufactured with different materials, sizes, and configurations to suit a wide range of applications, making them versatile in various industries.

Its important to note that while KLM finned tubes offer these advantages, the specific benefits may vary depending on the application and the operating conditions.