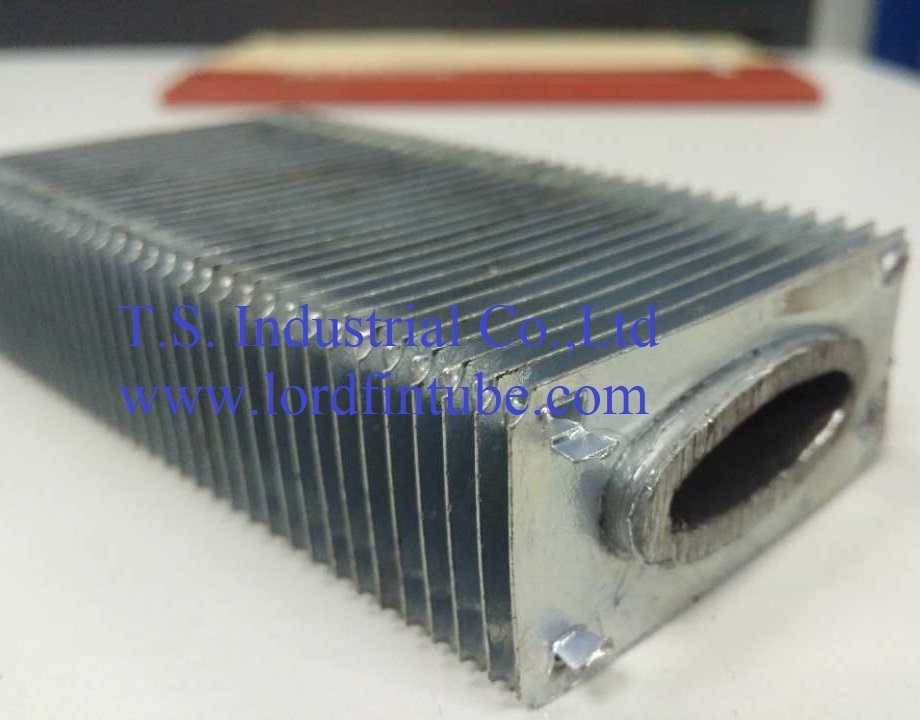

Lord Fin Tube-Welded aluminum fin tube

Welded Aluminum Finned Tubes

Welded aluminum fin tube in industrial heat exchange application

Welded Aluminum Finned Tubes Lifespan

The longevity of welded aluminum finned tubes represents a critical consideration for industrial applications where thermal efficiency and durability are paramount. These specialized components typically demonstrate exceptional service life ranging from 15 to 30+ years when properly specified, installed, and maintained.

Factors Determining Welded Aluminum Finned Tube Lifespan

Operating Conditions Impact

The operational environment significantly influences welded aluminum finned tubes longevity. Critical parameters include:

- Temperature extremes and thermal cycling frequency

- Pressure variations and mechanical stress

- Chemical composition of process fluids

- Presence of corrosive elements or particulates

- Velocity and turbulence of fluid flow

Material Quality Considerations

Aluminum alloy selection directly impacts welded aluminum finned tubes performance:

- Aluminum alloy grade and temper designation

- Corrosion resistance properties

- Thermal conductivity specifications

- Mechanical strength characteristics

- Compatibility with base tube materials

Manufacturing Excellence

Fabrication quality determines welded aluminum finned tubes structural integrity:

- Welding technique precision and consistency

- Filler material compatibility and quality

- Post-weld heat treatment procedures

- Fin attachment methodology and bond strength

- Quality control and testing protocols

Comprehensive Maintenance Strategies for Welded Aluminum Finned Tubes

Proactive Maintenance Protocols

Implementing systematic maintenance extends welded aluminum finned tubes service life significantly. Regular inspection intervals should be established based on operating severity, with comprehensive cleaning procedures to prevent fouling accumulation that compromises thermal performance and accelerates corrosion.

Effective maintenance of welded aluminum finned tubes involves both preventive and predictive approaches. Visual inspections should document fin condition, weld integrity, and any signs of corrosion initiation. Non-destructive testing methods, including ultrasonic examination and dye penetrant testing, can identify potential failure points before they develop into critical issues.

For welded aluminum finned tubes operating in corrosive environments, consider implementing corrosion monitoring coupons adjacent to the finned tube bundle. These coupons provide early warning of corrosion rates and help optimize chemical treatment programs.

Performance Comparison: Welded Aluminum Finned Tubes vs Alternative Technologies

| Parameter | Welded Aluminum Finned Tubes | Integral Low-Fin Tubes | Bimetallic Finned Tubes |

|---|---|---|---|

| Maximum Service Temperature | Up to 350°C | Up to 280°C | Up to 450°C |

| Thermal Contact Resistance | Very Low | None | Low |

| Corrosion Resistance | Excellent | Good | Variable |

| Fin Density Options | Wide Range | Limited | Moderate |

| Typical Lifespan | 15-30+ years | 10-20 years | 20-35 years |

Advanced Applications of Welded Aluminum Finned Tubes

Welded aluminum finned tubes deliver exceptional performance across diverse industrial applications. Their high thermal conductivity combined with excellent corrosion resistance makes them particularly suitable for:

Heat Recovery Systems

In waste heat recovery applications, welded aluminum finned tubes efficiently transfer thermal energy from exhaust streams to process fluids, achieving recovery efficiencies up to 75% while withstanding corrosive flue gas components.

Process Cooling

For industrial process cooling, welded aluminum finned tubes provide rapid heat dissipation with minimal fouling tendencies, maintaining consistent thermal performance throughout extended operation periods.

HVAC Systems

In commercial HVAC applications, welded aluminum finned tubes offer lightweight construction with maximized surface area for air-side heat transfer, contributing to system compactness and energy efficiency.

Optimize Welded Aluminum Finned Tube Performance

Maximize the lifespan and efficiency of your thermal systems with properly engineered welded aluminum finned tubes. Our technical experts can help you select the optimal configuration for your specific application requirements.

Consult Our Engineering TeamTechnical Specifications and Design Considerations

When specifying welded aluminum finned tubes, engineers must consider multiple technical parameters to ensure optimal performance and longevity. Fin geometry—including height, thickness, and spacing—should be optimized for the specific applications thermal and pressure drop requirements.

Material Selection

For welded aluminum finned tubes operating in mildly corrosive environments, aluminum alloy 1100 provides excellent corrosion resistance with good thermal conductivity. For applications requiring higher strength, alloy 3003 offers improved mechanical properties while maintaining corrosion resistance. In marine or highly corrosive environments, alloy 5052 delivers superior performance despite slightly reduced thermal conductivity.

The base tube material compatibility with the aluminum fins represents another critical consideration. Common combinations include carbon steel, stainless steel, and copper base tubes with aluminum fins, each offering distinct advantages for specific service conditions and temperature ranges.

Failure Analysis and Prevention Strategies

Understanding common failure modes enables proactive measures to extend welded aluminum finned tubes service life. Galvanic corrosion at the fin-to-tube interface represents the most prevalent failure mechanism, particularly when improper material combinations are specified or when protective coatings deteriorate.

Implement cathodic protection systems for welded aluminum finned tubes operating in conductive environments. This approach significantly reduces galvanic corrosion rates and can extend service life by 40-60% in aggressive conditions.

Other failure mechanisms include erosion-corrosion from high-velocity particulate matter, stress corrosion cracking in specific chemical environments, and thermal fatigue from excessive temperature cycling. Each failure mode requires distinct mitigation strategies, ranging from operational modifications to specialized protective coatings.

Maximizing Welded Aluminum Finned Tube Longevity

The service life of welded aluminum finned tubes depends on a complex interplay of design specifications, operational parameters, maintenance practices, and environmental conditions. Through proper material selection, meticulous fabrication, systematic maintenance, and operational awareness, these efficient heat transfer components can deliver decades of reliable service across diverse industrial applications.

Professional Recommendation: Consult with experienced thermal engineers during the design phase to optimize welded aluminum finned tubes configuration for your specific application. This proactive approach typically yields the best balance of performance, longevity, and lifecycle cost efficiency.