Lord Fin Tube-Heat conduction process of laser welding fin tube

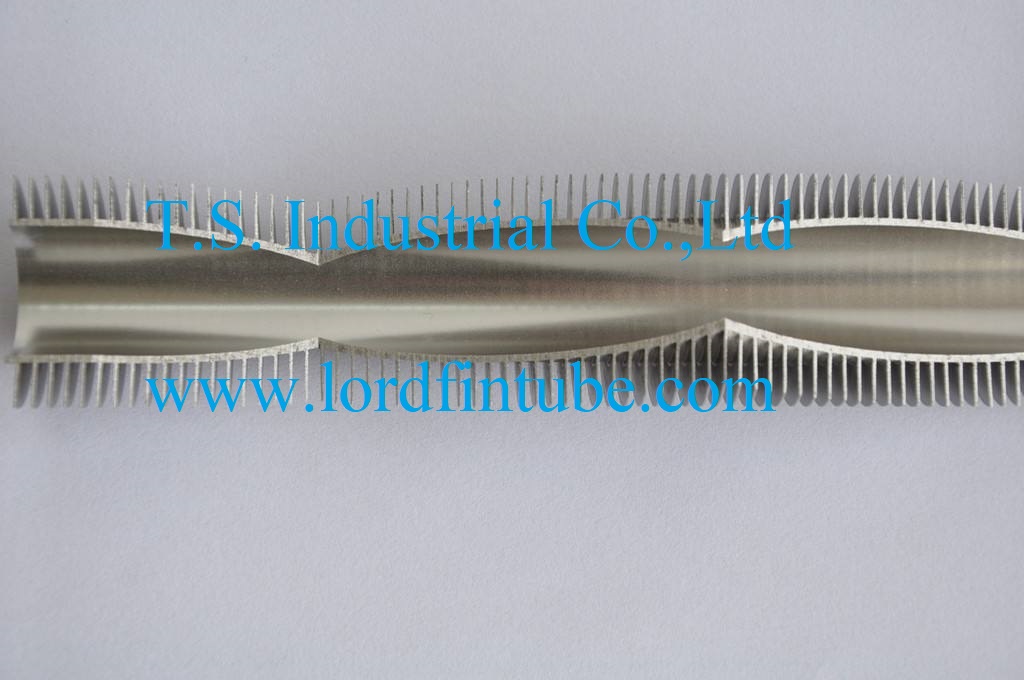

In industrial heat exchange applications, Laser welding fin tube technology represents a significant advancement in thermal efficiency and structural integrity. The laser welding process involves using a high-energy laser beam to melt and fuse metal components with exceptional precision, creating a metallurgical bond between the fin and base tube that ensures optimal heat transfer characteristics.

Three-Stage Heat Conduction Process in Laser Welded Fin Tubes

The thermal performance of laser welded fin tubes is governed by a sophisticated three-stage heat conduction mechanism that ensures maximum thermal efficiency in boiler and heat exchanger applications.

1. Heat Absorption Phase

During the initial phase, the laser beam energy is absorbed by the metal surface at the molecular level. The absorption efficiency depends on multiple factors including material composition, surface finish, and laser parameters. Unlike conventional welding methods, laser welding achieves absorption rates of 85-95% for most industrial metals, resulting in minimal energy loss.

Technical Insight: The localized heating in laser welding creates a heat-affected zone (HAZ) of only 0.5-1.5mm, compared to 3-5mm in traditional welding methods, preserving the base materials mechanical properties.

2. Heat Transfer Mechanism

The unique design of fin tubes significantly enhances heat transfer efficiency. The fins increase the effective surface area by 5-15 times compared to bare tubes, creating multiple conductive pathways for thermal energy. The laser-welded interface ensures continuous metallurgical bonding with thermal conductivity approaching 98% of the base materials theoretical maximum.

| Material Type | Thermal Conductivity (W/m·K) | Laser Weld Efficiency (%) | Traditional Weld Efficiency (%) |

|---|---|---|---|

| Carbon Steel | 54 | 96-98 | 85-90 |

| Stainless Steel 304 | 16 | 95-97 | 80-85 |

| Copper | 401 | 97-99 | 88-92 |

| Aluminum | 237 | 94-96 | 82-87 |

3. Heat Dissipation Process

As thermal energy propagates through the finned structure, controlled dissipation occurs through conduction, convection, and radiation. The optimized fin geometry and spacing ensure uniform temperature distribution, minimizing thermal stresses that can compromise component longevity in high-temperature applications.

Comparative Analysis: Laser vs. Traditional Welding Methods

Laser Welding Advantages

- Minimal heat-affected zone (0.5-1.5mm)

- Superior metallurgical bonding (95-99% efficiency)

- Precision control of weld penetration

- Reduced thermal distortion

- Higher production speed (2-3x faster)

- Consistent weld quality with automated systems

Traditional Welding Limitations

- Larger heat-affected zone (3-5mm)

- Lower bond efficiency (80-90%)

- Limited penetration control

- Higher thermal distortion

- Slower production rates

- Greater variability in weld quality

Heat Conduction Parameters

To maximize the thermal performance of Laser welding fin tube systems, several critical parameters must be carefully controlled:

| Parameter | Optimal Range | Impact on Heat Conduction | Industry Application |

|---|---|---|---|

| Laser Power | 2-6 kW | Determines penetration depth and bond quality | Boiler systems, Heat exchangers |

| Welding Speed | 2-10 m/min | Affects heat input and microstructural properties | Chemical processing, Power generation |

| Fin Thickness | 0.8-3.0 mm | Balances structural integrity with thermal resistance | Waste heat recovery, HVAC systems |

| Fin Density | 2-8 fins/inch | Optimizes surface area to flow resistance ratio | Refinery operations, Thermal oil heaters |

Critical Performance Metrics

- Thermal Efficiency: Laser-welded fin tubes achieve 15-25% higher thermal efficiency compared to traditional welded fins

- Pressure Resistance: Withstand operating pressures up to 1500 psi, ideal for high-pressure boiler applications

- Temperature Range: Operational from cryogenic temperatures (-200°C) to high-temperature applications (900°C)

- Service Life: Extended service life of 15-25 years in corrosive environments due to superior weld integrity

Industrial Applications and Performance Data

The advanced heat conduction properties of laser welded fin tubes make them indispensable across multiple industries. Performance data collected from field applications demonstrates their superior thermal characteristics:

| Application Sector | Heat Transfer Improvement | Energy Savings | Maintenance Reduction |

|---|---|---|---|

| Power Generation Boilers | 18-22% | 12-15% | 30-40% |

| Chemical Process Heaters | 20-25% | 15-18% | 25-35% |

| Refinery Heat Exchangers | 15-20% | 10-14% | 20-30% |

| Waste Heat Recovery | 22-28% | 18-22% | 35-45% |

The precision of the laser welding process ensures consistent thermal performance across the entire finned surface, eliminating hot spots and thermal stress concentrations that commonly plague traditionally welded fin tubes. This results in more predictable heat exchange rates and enhanced system reliability in critical industrial processes.