Lord Fin Tube-Mechanical-forming thermal-transfer tubes

About Finned Tubes Types

Finned tubes are essential components in heat exchangers, boilers, and various industrial heating/cooling systems. This comprehensive guide explores the different types of finned tubes, their specifications, performance characteristics, and industrial applications.

Finned Tubes Overview

Finned tubes are specialized heat transfer components designed to increase the surface area for heat exchange between fluids. By adding fins to the base tube, these components significantly enhance thermal efficiency in various industrial applications.

Performance Advantage

Finned tubes can increase heat transfer efficiency by 200-400% compared to bare tubes, making them essential for energy-intensive industrial processes where thermal efficiency directly impacts operational costs.

Types of Finned Tubes

Finned tubes are primarily categorized into two manufacturing types: mechanical-formed and welding-formed tubes. Each type offers distinct advantages for specific applications and operating conditions.

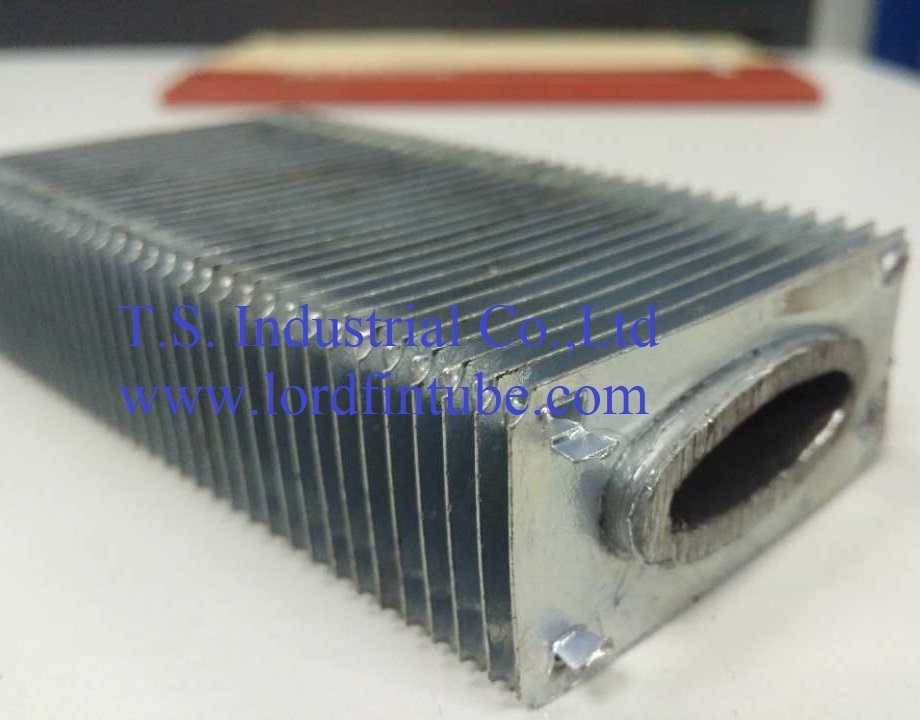

1. Mechanical-formed Thermal-transfer Tubes

Mechanical-formed thermal-transfer tubes are created through specialized forming processes that shape the fin material without welding. These tubes offer excellent thermal conductivity and durability in demanding environments.

DR Type - Extruded High Fin Tube

Available in solid and serrated fin configurations. Extruded fins provide excellent heat transfer with maximum surface area. Ideal for applications requiring high thermal efficiency in clean gas environments.

L Type - Tension Wound Spiral Fin Tube

Features fins wound under tension for secure attachment. Suitable for moderate temperature applications with excellent corrosion resistance and cost-effectiveness.

LL Type - Overlapped Footed Spiral Fin Tube

Overlapped fin design provides enhanced mechanical stability. Perfect for applications with vibration or thermal cycling where fin integrity is critical.

KL/KLM Type - Tension Wound Knurled Footed Fin Tube

Knurled foot design ensures maximum fin-to-tube contact. Excellent for high-temperature applications where thermal expansion must be accommodated.

G Base Type - Embedded Fluted Fin Tube

Unique fluted design increases turbulence and heat transfer. Particularly effective in applications with low flow rates or viscous fluids.

Low Fin Type - Integral Low Fin Tube

Manufactured with integral fins from the base tube material. Offers superior mechanical strength and is available with knurled options for enhanced performance.

2. Welding-formed Thermal-transfer Tubes

Welding-formed thermal-transfer tubes utilize various welding techniques to attach fins to the base tube. These tubes provide exceptional bond strength and can withstand extreme temperatures and pressures.

HFW Type - ERW High Frequency Resistance Welding

Available with solid and serrated fins. High-frequency welding ensures consistent, high-quality bonds. Excellent for high-pressure applications and corrosive environments.

H/HH Type - DC Welding Square/Rectangular Fin Tube

Square or rectangular fin configuration maximizes surface area in constrained spaces. Ideal for compact heat exchanger designs where space optimization is critical.

Studs Type - ERW Studded Tube

Studded design creates turbulence for enhanced heat transfer. Particularly effective in fluidized bed applications and other high-turbulence environments.

Mechanical-formed thermal-transfer tubes in various configurations

Technical Comparison of Finned Tube Types

| Parameter | Mechanical-formed Tubes | Welding-formed Tubes |

|---|---|---|

| Maximum Temperature | Up to 350°C | Up to 650°C |

| Thermal Resistance | Low (0.0001 m²K/W) | Very Low (0.00005 m²K/W) |

| Pressure Rating | Medium (up to 150 bar) | High (up to 300 bar) |

| Corrosion Resistance | Excellent | Good to Excellent |

| Vibration Resistance | Good | Excellent |

| Cost Efficiency | High | Medium to High |

| Typical Applications | Air coolers, HVAC, moderate temp heat exchangers | Boilers, high-temp heat exchangers, fired heaters |

Performance Characteristics

Relative Heat Transfer Efficiency

Industry Data: Finned Tube Market

The global finned tube market is projected to reach $12.5 billion by 2027, growing at a CAGR of 6.2%. Mechanical-formed tubes currently hold 58% market share, while welding-formed tubes account for 42%, with the latter showing faster growth due to increasing high-temperature applications.

Finned Tube Material Specifications

Common Materials for Finned Tubes

Carbon Steel

Cost-effective for non-corrosive applications. Temperature range: -20°C to 400°C

Stainless Steel

Excellent corrosion resistance. Common grades: 304, 316, 321. Temperature range: -200°C to 800°C

Copper & Alloys

Superior thermal conductivity. Ideal for high-efficiency applications. Temperature range: -100°C to 250°C

Aluminum

Lightweight with good corrosion resistance. Often used for air-cooling applications. Temperature range: -270°C to 200°C

ASTM Standard Specifications

| Standard | Description | Application |

|---|---|---|

| ASTM A 249/A 249M | Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes | High-temperature pressure applications |

| ASTM A269/A269M | Seamless and Welded Austenitic Stainless Steel Tubing for General Service | General corrosion-resistant applications |

| ASTM A312/A312M | Seamless and Welded Austenitic Stainless Steel Pipes | High-temperature and corrosive service |

| ASTM A 688 / SA 688 | Welded Feed Water Heater U Tubes | Power plant feed water heaters |

| ASTM A789/A789M | Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing | Corrosive and high-stress applications |

Finned Tube Industrial Applications

Primary Industries Using Finned Tubes

- Power Generation: Boilers, economizers, superheaters, air preheaters

- Chemical Processing: Reactors, distillation columns, condensers

- Oil & Gas: Heaters, coolers, compressors, refinery processes

- HVAC: Air handling units, chillers, heat recovery systems

- Manufacturing: Process heating, drying systems, industrial ovens

- Marine: Shipboard cooling systems, engine heat recovery

- Renewable Energy: Solar thermal systems, geothermal applications

- Food & Beverage: Pasteurizers, sterilizers, process cooling

Application-Specific Selection Guidelines

For high-temperature applications above 400°C, welded fin tubes are recommended. For corrosive environments with temperatures below 350°C, mechanical-formed tubes with appropriate material selection provide the best balance of performance and cost.

Key Technical Takeaways

- Mechanical-formed tubes offer cost efficiency for moderate temperature applications

- Welding-formed tubes provide superior performance in high-temperature and high-pressure environments

- Material selection should consider temperature, corrosion resistance, and thermal conductivity requirements

- Proper fin type selection can improve heat transfer efficiency by up to 400% compared to bare tubes

- Regular maintenance and inspection are critical for maximizing finned tube lifespan and performance

Lord Fin Tube Additional Services

Beyond standard finned tube manufacturing, specialized services include custom Elliptical Finned Tubes, elbows, bends, U-tube configurations, tube swaging, and custom tube supports and spacer boxes in various materials including Stainless Steel, Aluminum, and Galvanized/Zinc coatings.