Products Description

1. What is Oval Spiral Finned Tube?

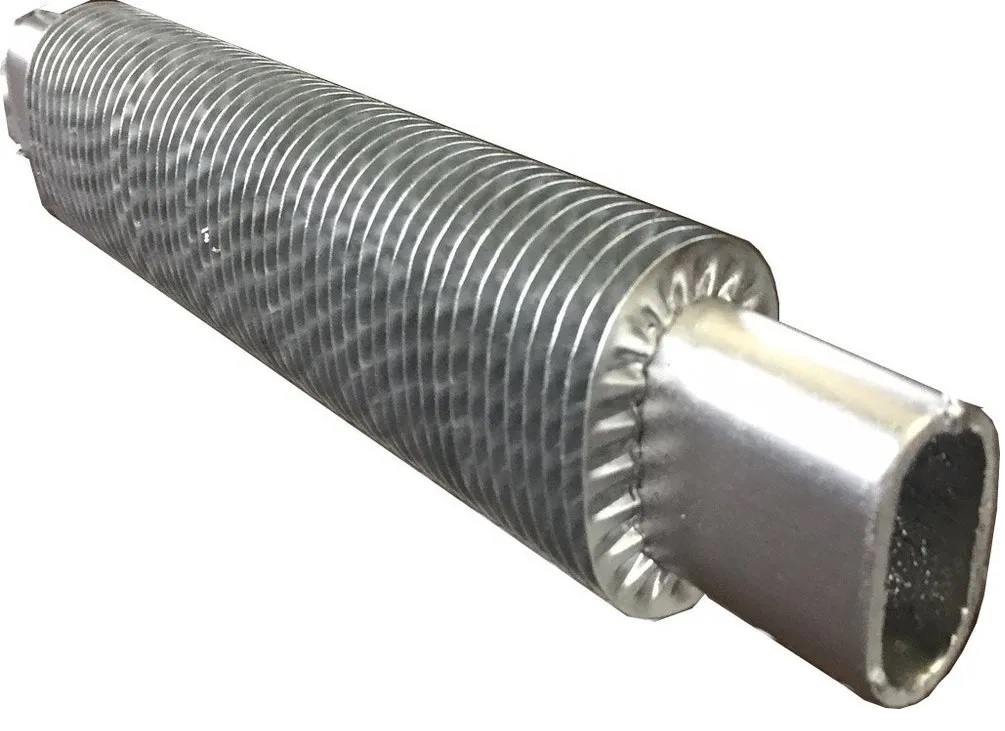

An oval spiral finned tube, also known as an elliptical spiral fin tube, represents a significant advancement in heat transfer technology. This specialized component consists of an oval-shaped base tube with continuous fins spirally wound around its exterior surface. The unique geometry creates a highly efficient thermal exchange interface between the internal fluid medium and the external environment.

Technical Insight:

The elliptical cross-section provides approximately 15-20% more surface area compared to circular tubes of equivalent cross-sectional area. This geometric advantage, combined with the spiral fin configuration, creates turbulent flow conditions that disrupt boundary layers and significantly enhance heat transfer coefficients.

The aerodynamic profile of oval tubes reduces form drag and pressure drop across tube banks, making them particularly advantageous in air-cooled applications. When combined with spiral fins, the resulting component delivers exceptional thermal performance in compact footprints, addressing critical space and efficiency constraints in modern industrial systems.

2. Manufacturing Process

The fabrication of oval spiral finned tubes involves precision engineering and specialized equipment to ensure optimal fin geometry, attachment integrity, and thermal performance.

Elliptical Spiral Fin Tube Manufacturing Stages:

- Tube Formation: Round tubes are mechanically or hydraulically formed into precise elliptical profiles with controlled ovality ratios.

- Fin Winding: Continuous strip material is fed through forming rolls and spirally wound onto the oval tube under controlled tension.

- Fin Attachment: Fins are securely attached using various methods including tension winding, L-foot embedding, or welding depending on application requirements.

- Quality Verification: Each tube undergoes dimensional inspection, non-destructive testing, and sample thermal performance validation.

Manufacturing Innovation:

Advanced manufacturing techniques now allow for variable fin density along the tube length, optimizing thermal performance for applications with changing fluid properties or temperature profiles. This graded fin approach maximizes efficiency while minimizing material usage and pressure drop.

3. Material Selection

Material selection for oval spiral finned tubes is critical for performance, longevity, and cost-effectiveness. The optimal material combination depends on operating conditions, fluid compatibility, and thermal requirements.

| Material Combination | Base Tube Materials | Fin Materials | Typical Applications | Temperature Range |

|---|---|---|---|---|

| Standard Carbon Steel | CS, ASTM A179 | Carbon Steel | Air Heaters, Economizers | -20°C to 400°C |

| Stainless Steel Series | 304, 316, 321 SS | 304, 316, 321 SS | Corrosive Environments, Food Processing | -200°C to 800°C |

| High-Temperature Alloys | Inconel, Hastelloy | Inconel, Hastelloy | Furnaces, High-Temp Reactors | Up to 1150°C |

| Bimetallic Options | Carbon Steel | Aluminum, Copper | Air Coolers, HVAC | -50°C to 280°C |

| Corrosion Resistant | Duplex, Super Duplex | Duplex, Super Duplex | Marine, Chemical Processing | -50°C to 300°C |

Material Engineering Insight:

For bimetallic oval spiral finned tubes, the thermal expansion coefficient mismatch between base tube and fin material must be carefully considered. Advanced manufacturing techniques now incorporate transition layers and specialized attachment methods to accommodate differential expansion, preventing fin loosening or detachment during thermal cycling.

Specialized Coatings and Treatments:

Various surface treatments enhance performance in specific applications:

- Hot-Dip Galvanizing: Zinc coating for corrosion protection in outdoor applications

- Aluminizing: Aluminum diffusion coating for high-temperature oxidation resistance

- Organic Coatings: Epoxy, phenolic, or polymer coatings for chemical resistance

- Electroless Nickel: Uniform corrosion-resistant coating for complex geometries

4. Why Choose Oval Spiral Finned Tube?

Oval spiral finned tubes offer distinct advantages over conventional circular finned tubes in many applications. The combination of elliptical tube geometry and spiral fin configuration creates synergistic benefits.

Enhanced Thermal Efficiency

The oval profile increases heat transfer surface area by 15-20% compared to circular tubes of equivalent cross-section. Spiral fins create turbulence that disrupts thermal boundary layers, improving heat transfer coefficients by 25-40%.

Reduced Pressure Drop

The streamlined elliptical shape significantly reduces form drag and wake turbulence, lowering air-side pressure drop by 30-50% compared to circular tubes in crossflow applications.

Compact Design

Higher surface area density allows for more compact heat exchanger designs, reducing equipment footprint by 20-35% while maintaining equivalent thermal duty.

Fouling Resistance

The spiral fin geometry creates variable flow paths that reduce particulate deposition and make cleaning more effective compared to straight fin configurations.

Structural Integrity

The elliptical cross-section provides superior resistance to flow-induced vibration and mechanical stress, extending service life in demanding applications.

Material Optimization

Bimetallic construction allows cost-effective pairing of expensive corrosion-resistant fin materials with economical base tube materials.

Oval Spiral Finned Tubes

- Higher heat transfer efficiency

- Lower pressure drop

- Reduced fouling tendency

- Compact footprint

- Superior vibration resistance

- Better cleaning accessibility

Traditional Circular Finned Tubes

- Standard manufacturing process

- Lower initial cost

- Extensive application history

- Wider supplier availability

- Simpler replacement logistics

- Established design codes

5. Application Fields

Oval spiral finned tubes and elliptical spiral fin tubes serve critical functions across diverse industrial sectors where efficient heat transfer is essential.

Power Generation

Air-cooled condensers, feedwater heaters, turbine oil coolers, and HRSG applications where compactness and efficiency are paramount.

HVAC & Refrigeration

Large-scale chillers, air handling units, and heat recovery systems where space constraints and energy efficiency drive equipment selection.

Chemical Processing

Reactors, distillation columns, and process heaters handling corrosive media where material compatibility and fouling resistance are critical.

Oil & Gas

Production facilities, refineries, and LNG plants where reliability under extreme conditions and fouling mitigation are essential.

Marine Applications

Compact heat exchangers for engine cooling, lubricant cooling, and HVAC systems where space and weight savings are valuable.

Waste Heat Recovery

Systems capturing thermal energy from exhaust streams where pressure drop minimization and compact design optimize economic returns.

Emerging Applications:

Recent developments in oval spiral finned tube technology have enabled new applications in renewable energy systems, including concentrated solar power receivers, biomass energy plants, and advanced nuclear reactor cooling systems. The unique thermal and mechanical properties of these components make them ideal for next-generation energy technologies.

Oval Spiral Finned Tube

Oval spiral finned tubes and elliptical spiral fin tubes represent a sophisticated heat transfer solution that delivers superior performance in demanding applications. The unique combination of elliptical tube geometry and spiral fin configuration provides enhanced thermal efficiency, reduced pressure drop, and improved mechanical reliability compared to conventional circular finned tubes.

With proper material selection and manufacturing quality control, these components offer long service life and maintenance advantages across power generation, chemical processing, HVAC, and specialized industrial applications. As thermal management requirements continue to evolve, the advanced properties of oval spiral finned tubes position them as a key technology for efficient and compact heat exchange systems.