What is resistance welding studded pipe?

What is Resistance welding studded pipe?

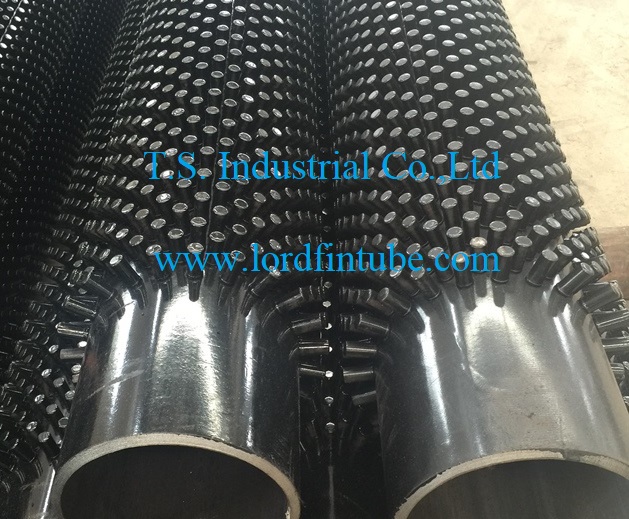

Resistance welding studded pipe is a type of welded pipe used in industrial applications that require high temperature and high pressure resistance. It is made by welding small studs onto the surface of a steel pipe using a resistance welding process, which involves applying an electric current to the studs and the pipe surface to melt and fuse them together. The studs are typically made of a material that is highly resistant to heat and corrosion, such as stainless steel or other alloys.

Resistance welding studded pipe is commonly used in industries such as oil and gas, petrochemicals, and power generation, where it is used in applications such as heat exchangers, boilers, and pressure vessels. Its unique design allows for efficient heat transfer and high strength, making it a popular choice for these demanding industrial applications.

To perform resistance welding studded pipe, a stud is placed against the surface of the pipe or workpiece and held in place with a special welding gun. The gun delivers a high-current electrical pulse through the stud and into the workpiece, heating the metal to a temperature where it becomes molten.

As the metal cools, it solidifies and forms a strong bond between the stud and the pipe. This process is typically performed using specialized equipment, such as a stud welding machine, which can be programmed to deliver precise electrical pulses for consistent and reliable results.

Resistance welding studded pipe is commonly used in industrial applications where strong, reliable connections are required, such as in the construction of pipelines, pressure vessels, and other metal structures. The process is also used in the fabrication of heat exchangers and other specialized equipment.

Resistance welding studded pipes are commonly used in industrial fields that require high temperature and high pressure fluid transmission or heat exchange, such as:

1. Chemical industry: such as refineries, fertilizer plants, ethylene plants, and adipic acid plants;

2. Petroleum and natural gas industry: such as oil wells, natural gas pipelines, petrochemical facilities, etc.;

3. Power industry: such as thermal power plants, nuclear power plants, etc.