Products Description

1. SA182 F51 Tube Sheets

We specialize in manufacturing forged duplex stainless steel tube sheets compliant with the ASME SA182 F51 (UNS S31803) standard. This material represents the ideal solution for modern industries facing demanding corrosive environments and high-strength requirements. SA182 F51 tube sheets are the preferred choice for critical equipment in chemical, oil & gas, marine engineering, seawater desalination, power generation, and pulp & paper industries, thanks to their exceptional corrosion resistance (especially against chloride stress corrosion cracking), outstanding mechanical strength, and good weldability.

2. Core Advantages & Performance Features:

Unmatched Corrosion Resistance:

Superior resistance to chloride pitting and crevice corrosion (high PREN value 40). Excellent resistance to chloride stress corrosion cracking (SCC), significantly outperforming 304/316 austenitic stainless steels. Good resistance to general acids, alkalis, and salt corrosion.

Exceptional Mechanical Strength:

Yield strength and tensile strength are approximately twice that of common austenitic stainless steels (e.g., 304L, 316L). This allows for thinner tube sheets under identical design conditions, reducing equipment weight and cost. Excellent fatigue strength and wear resistance.

Good Machinability & Weldability:

Although high-strength, it offers good machinability (drilling tube holes, turning, etc.) with professional equipment and processes.Good weldability when following correct duplex stainless steel welding procedures (e.g., controlled heat input, matching filler metals). We can provide technical support.

Cost-Effectiveness:

While material cost per unit may be higher than austenitic stainless steels, its longer service life, higher reliability, and potential for reduced thickness design offer significant lifecycle cost advantages.

3. SA182 F51 Tube Sheets Typical Applications:

SA182 F51 tube sheets are the ideal choice for the following critical equipment:

Shell & Tube Heat Exchangers & Condensers (especially involving seawater, chloride-containing media, high temperature/pressure)

Reactors & Pressure Vessels (for handling corrosive chemicals, acidic oil & gas)

Seawater Desalination Plants (high-pressure sections of Multi-Stage Flash - MSF, Reverse Osmosis - RO)

Flue Gas Desulfurization (FGD) Systems

Oil & Gas Exploration & Processing Equipment (offshore platforms, subsea pipeline terminals)

Pulp & Bleaching Equipment Any application requiring high strength combined with superior corrosion resistance in tube sheets.

4. Our Manufacturing Capabilities & Service Commitment:

Strict Material Sourcing:

Procure raw materials only from reputable mills, fully compliant with SA182 F51 standard and accompanied by complete Material Test Certificates (MTC).

Advanced Forging Technology:

Employ precision forging techniques to ensure material density, flow line integrity, and excellent mechanical properties.

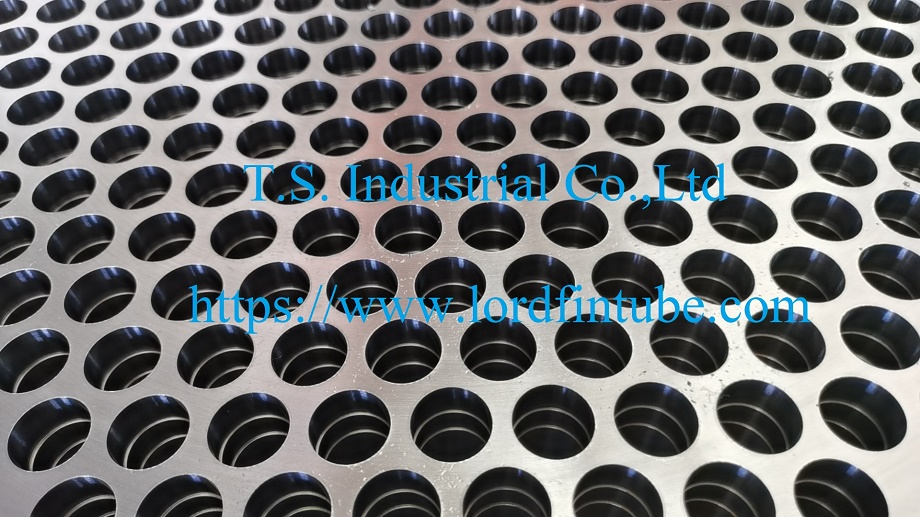

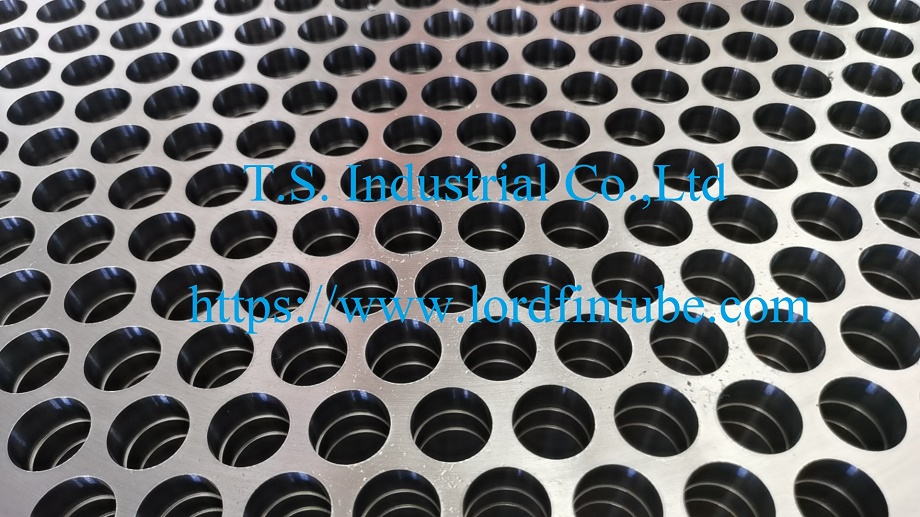

Precision Machining Capabilities:

High-precision CNC drilling (guaranteeing tube hole dimensions, positional accuracy, perpendicularity, surface finish). Precision machining of faces, OD, grooves, etc., using large lathes/vertical boring mills. Capable of machining tube sheets of various sizes, thicknesses, and complex shapes.

Rigorous Quality Control:

Full-process quality monitoring (incoming material inspection, in-process dimensional control, NDT - UT/MT/PT, final inspection). Provide complete quality documentation package (Material Certificates, Heat Treatment Reports, NDT Reports, Dimensional Inspection Reports). Compliance with international standards like ASME Section VIII, EN 10204 3.1/3.2.

Professional Expertise:

Years of experience in machining duplex tube sheets, with deep understanding of material properties and application challenges. We offer expert material selection and manufacturing advice.

Customization Service:

Provide tube sheets customized to your drawings and specifications, including bespoke dimensions, tolerances, surface finishes, and special requirements (e.g., cladding). Reliable Delivery: Efficient production management and logistics ensure on-time delivery.

5. Why Choose Our SA182 F51 Tube Sheets?

Quality Guaranteed: Rooted in strict material control and advanced manufacturing processes.

Reliable Performance: Ensures durable and safe operation of your critical equipment in harsh environments.

Optimized Costs: Helps reduce overall equipment and maintenance costs through material advantages and our machining efficiency.

One-Stop Service: Full support from material consultation, precision machining to quality documentation provision.

Technical Partnership: We are not just a supplier, but your technical partner in tackling corrosion challenges.

Capability for extra-large/extra-thick tube sheets. Unique drilling technology for precision and efficiency. Special heat treatment offerings.

SA182 F51 Tube Sheet