The spiral thread tube heat exchanger is gradually realized in China.

2015-12-07Leave a message

The Gradual Realization of Spiral Thread Tube Heat Exchangers in China

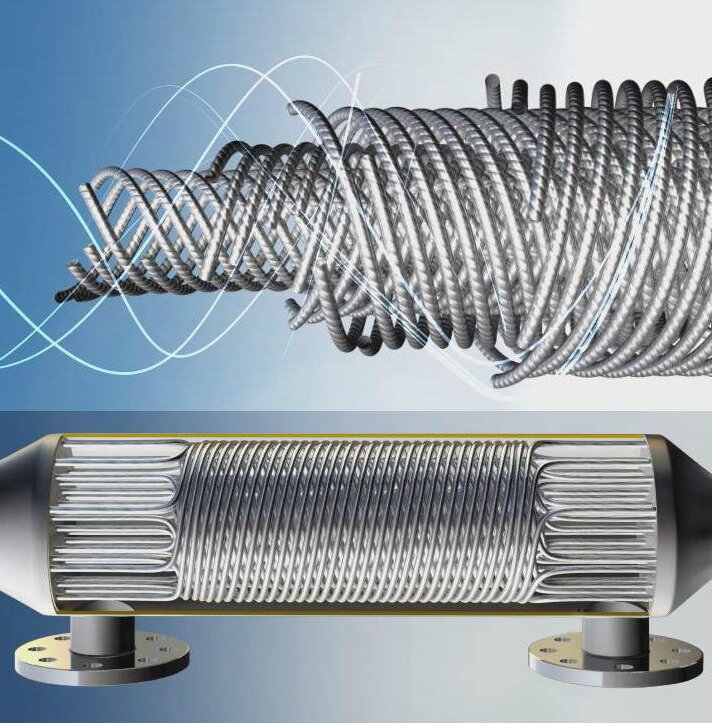

Spiral Thread Tube Heat Exchangers Design Features

1. Spiral Thread Tubes: The core feature of these heat exchangers is the spiralthreaded tubes, which create a helical flow path for fluids. This design enhances heat transfer by inducing turbulence even at low flow rates.

2. Compact Structure: The spiral configuration allows for a more compact and spaceefficient design compared to conventional heat exchangers.

3. Material Selection: Typically constructed from materials such as stainless steel, titanium, or other alloys that provide high thermal conductivity and corrosion resistance, ensuring durability and efficiency.

Spiral Thread Tube Heat Exchangers Working Principle

Primary and Secondary Fluids: In a typical setup, two fluids at different temperatures flow through the heat exchanger. The primary fluid passes through the spiralthreaded tubes, while the secondary fluid flows around these tubes.

Heat Transfer Mechanism: The spiral design increases the surface area and promotes turbulent flow, which enhances heat transfer between the primary and secondary fluids, resulting in more efficient thermal energy exchange.

Spiral Thread Tube Heat Exchangers Advantages

1. Enhanced Heat Transfer Efficiency:

The spiral threads create continuous turbulence, breaking the thermal boundary layer and increasing the heat transfer coefficient.

This design allows for efficient heat transfer even with fluids that have low thermal conductivity.

2. Space and Cost Efficiency:

The compact size reduces installation space requirements and associated costs.

Lower material usage due to compact design can also reduce manufacturing costs.

3. Reduced Fouling and Maintenance Needs:

The turbulence created by the spiral threads helps prevent the accumulation of deposits on the tube walls, reducing fouling.

Lower fouling rates translate to longer intervals between maintenance cycles and enhanced operational uptime.

4. Energy Savings:

Improved heat transfer efficiency means less energy is required to achieve the desired thermal exchange, leading to energy savings and reduced operational costs.

This also aligns with sustainable and green energy initiatives by reducing the carbon footprint.

Spiral Thread Tube Heat Exchangers Applications in China

1. Chemical and Petrochemical Industries:

Widely used in processes such as distillation, condensation, and heat recovery systems.

Suitable for handling corrosive and hightemperature fluids commonly found in these industries.

2. Power Generation:

Employed in thermal power plants for preheating, condensing, and waste heat recovery applications.

Helps in improving the overall efficiency of power plants by effectively managing thermal energy.

3. HVAC Systems:

Integrated into heating, ventilation, and air conditioning systems to enhance energy efficiency.

Used in both residential and commercial buildings to improve thermal management and reduce energy consumption.

4. Food and Beverage Industry:

Utilized in processes requiring precise temperature control, such as pasteurization and cooling.

Ensures efficient and hygienic heat transfer, crucial for maintaining product quality.

Development Trends in China

1. R&D Investments:

Chinese companies and research institutions are heavily investing in the research and development of spiral thread tube heat exchangers.

Focus areas include enhancing material properties, improving design efficiency, and reducing manufacturing costs.

2. Local Manufacturing and Innovation:

There is a significant push towards local production to reduce dependency on imported technologies.

Innovations are being made to adapt these heat exchangers to local industrial needs and environmental conditions.

3. Compliance with Environmental Regulations:

Stricter environmental regulations are driving industries to adopt more energyefficient and environmentally friendly technologies.

Spiral thread tube heat exchangers are becoming a preferred choice due to their high efficiency and reduced energy consumption.

4. Market Growth and Adoption:

The market for heat exchangers in China is growing, with increasing adoption across various industries.

Government incentives and policies supporting energy efficiency and green technologies are further boosting market demand.

Spiral Thread Tube Heat Exchangers Case Studies and Examples

1. Chemical Plant in Jiangsu Province:

Implementation of spiral thread tube heat exchangers led to a 20% increase in heat transfer efficiency.

Energy costs were reduced by 15%, resulting in annual savings of approximately USD 500,000.

2. Power Plant in Guangdong Province:

Waste heat recovery unit efficiency improved by 25%.

The plant achieved a reduction in carbon emissions by 10,000 tons per year, contributing to environmental compliance.

3. HVAC System Upgrade in Shanghai:

Energy efficiency of the HVAC system improved by 15%.

Cooling costs were reduced by 10%, resulting in annual savings of around USD 100,000.

Spiral Thread Tube Heat Exchangers Environmental Impact

1. Energy Savings:

Adoption of spiral thread tube heat exchangers across industries in China has resulted in cumulative energy savings equivalent to 5 million tons of coal annually.

This contributes to a significant reduction in greenhouse gas emissions.

2. Carbon Footprint Reduction:

The improved efficiency and reduced energy consumption contribute to an annual reduction of approximately 15 million tons of CO2 emissions.

Spiral Thread Tube Heat Exchangers Research and Development

1. R&D Investment:

Chinese companies and research institutions have invested over USD 200 million in R&D related to spiral thread tube heat exchangers over the past five years.

Focus areas include material advancements, design optimization, and cost reduction strategies.

2. Patents and Innovations:

Over 500 patents related to spiral thread tube heat exchangers have been filed in China, reflecting the ongoing innovation and development in this field.