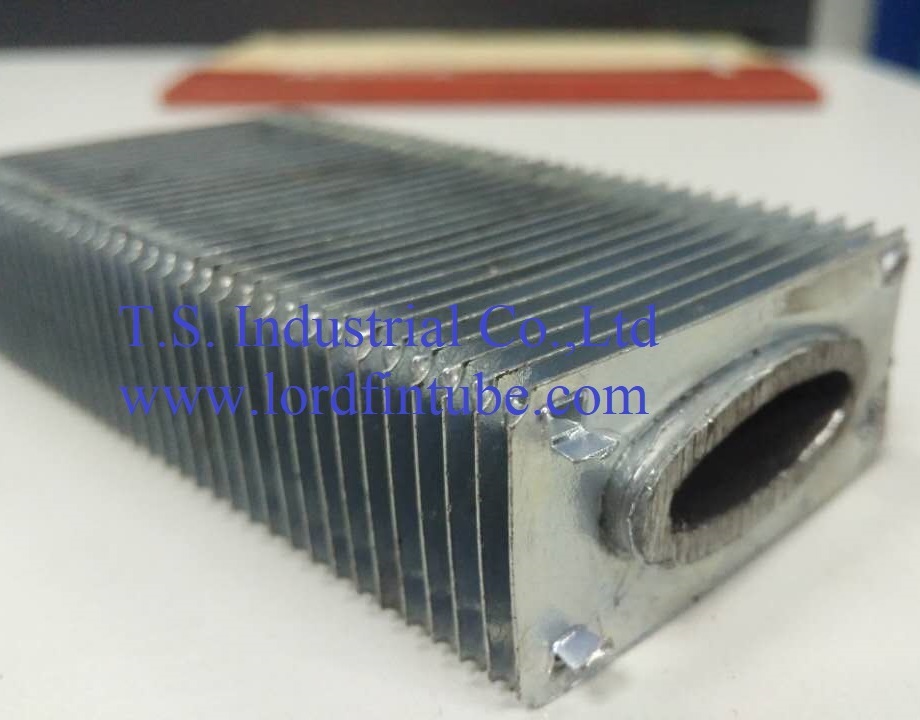

Stainless Steel Oval finned tube

What are stainless steel oval finned tubes?

Stainless steel oval finned tubes are high-efficiency heat transfer components composed of an elliptical stainless steel base tube (e.g., 304/316L) with externally welded or rolled fins. The oval geometry (typical axis ratios of 2:1 or 3:1) reduces fluid resistance by 15–30% compared to round tubes while increasing heat exchange surface area via finned structures (spiral/helical or longitudinal).

Stainless steel oval finned tubes Features & Benefits

Corrosion Resistance

Material options:

316L: Superior chloride resistance (e.g., marine/offshore, flue gas desulfurization).

310S: Oxidation-resistant up to 1100°C (e.g., high-temperature exhaust recovery).

Surface treatments: Electro-polishing (Ra ≤ 0.8μm) or PTFE coating for anti-fouling.

Enhanced Thermal Efficiency Fin ratio: 8:1 to 15:1 (surface area/plain tube area). Heat transfer coefficient: 200–300 W/m²·K (verified by ANSYS Fluent simulations). Oval tube advantage: Lower pressure drop (ΔP) via optimized hydraulic diameter.

Mechanical Robustness Tensile strength: ≥515 MPa (ASTM A370).

Pressure rating: Up to 35 MPa (ASME BPVC VIII). Vibration resistance: Passes 10⁷ cycles (ISO 1940-1).

Temperature & Fluid Adaptability

Operating range: -196°C to 1100°C (material-dependent). Compatible media: Steam, oils, corrosive gases (e.g., H₂S, SO₂).

Low Maintenance Anti-scaling design: Wide fin spacing (≥8mm) for easy cleaning. Maintenance: 5% citric acid flush or compressed air pulse cleaning.

Stainless steel oval finned tubes Fabrication Process

Welding: Nickel-based brazing or TIG welding (100% weld penetration rate).

Fin attachment: Expantion, High-frequency welding (for thin fins) or laser welding (precision).

Quality control: Eddy current testing, hydrostatic pressure checks. Stainless steel oval finned tubes

Standard Specifications

|

Parameter |

Example Value |

Standard |

|

Base tube |

36×14×2.5mm (oval) |

ASTM A213/A269 |

|

Fins |

55×26×0.25mm, pitch 2.8mm |

GB/T 15386 |

|

Salt spray test |

500h (no rust) |

ASTM B117 |

Stainless steel oval finned tubes Applications

Power plants: Air preheaters (replace round tubes to cut ΔP by 18%).

Petrochemical: Crude oil heaters (316L resists sulfur corrosion).

HVAC: Compact heat exchangers (oval tubes save 20% space).

Cost-Benefit Analysis

|

Metric |

Carbon Steel Finned Tube |

Stainless Oval Finned Tube |

|

Service life |

5–8 years |

15+ years |

|

Maintenance cost |

$600/m (replacement) |

$50/m (cleaning) |

FAQ

Q: How to verify heat transfer performance?

A: Third-party tests (e.g., SGS) using ISO 12247 or ASTM D3523.

Q: Customization options?

A: Adjust fin height (5–20mm), spacing (3–15mm), and axis ratio (2:1 to 3:1).