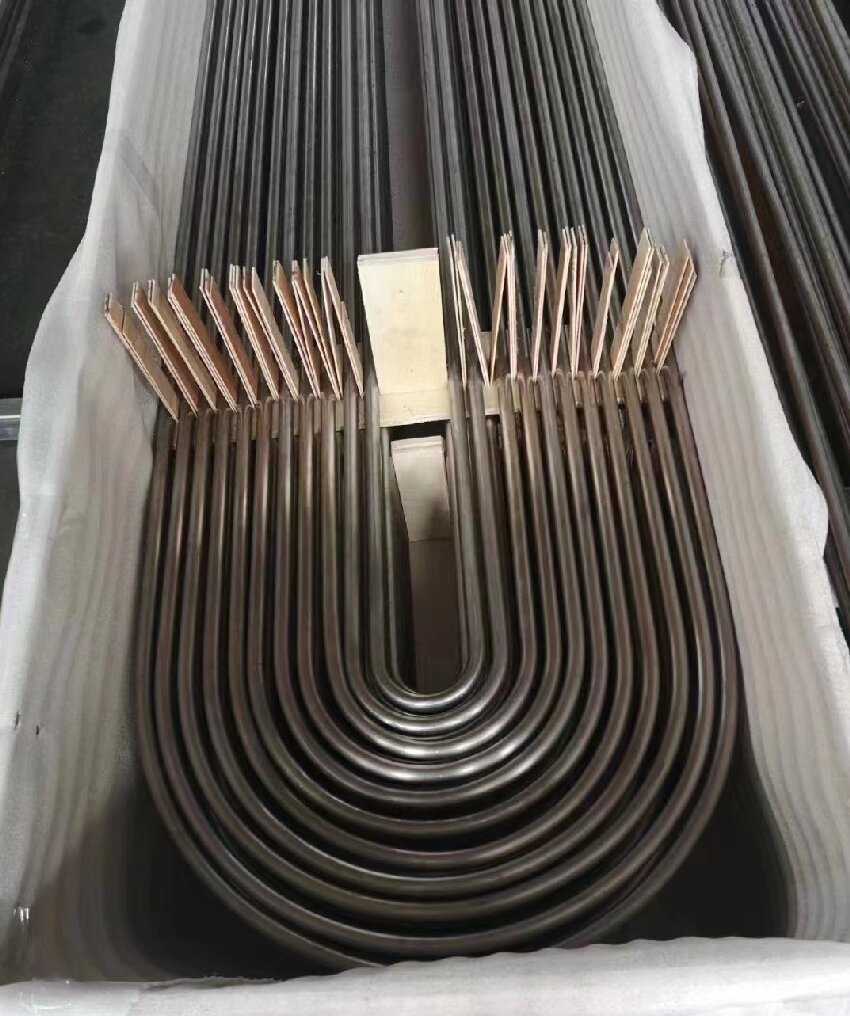

Stainless steel U bent Tube standard and material grade

Stainless steel U-bent tubes are specialized components extensively used in heat exchangers, boilers, condensers, and various industrial applications. Their unique U-shaped configuration allows for thermal expansion and contraction while maximizing heat transfer efficiency in compact spaces.

Stainless steel U-bent tubes Material Standards and Specifications

Stainless steel U-bend tubes adhere to a variety of standards and material grades tailored to meet specific application requirements. Below are detailed descriptions of commonly employed standards and material grades for stainless steel U-bend tubes:

| Standard Specification | Material Grades | Key Properties | Typical Applications |

|---|---|---|---|

| ASTM/ASME A/SA213 | TP304/304L, TP316/316L, TP310S, TP304H, TP347/347H, TP316Ti, TP321/321H | High temperature strength, oxidation resistance, excellent corrosion resistance | Boilers, superheaters, heat exchangers |

| ASTM/ASME A/SA268 | TP405, TP409, TP410, TP430, TP439, TP444 | General corrosion resistance, high-temperature applications | Automotive exhaust systems, heat treatment equipment |

| ASTM/ASME A/SA249 | TP304/304L, TP304H, TP316/316L, TP347/347H, TP316Ti, TP321/321H, TP310S | Excellent weldability, formability, corrosion resistance | Boilers, heat exchangers, condensers |

| ASTM/ASME A/SA269 | TP304/304L, TP316/316L | General corrosion resistance, high cleanliness, good mechanical properties | General service applications, low/high-temperature service |

| ASTM B165, B167, B444, B407, B423 | Monel400, UNS N06600, Inconel625, Incoloy800/800H, Incoloy825 | Exceptional corrosion resistance, high-temperature strength | Chemical processing, marine engineering, aerospace |

| ASTM A789/A790 | Duplex UNS S31803/32205, UNS S32750 | High strength, excellent chloride corrosion resistance | Oil and gas, chemical processing, marine engineering |

Stainless steel U-bent tubes Technical Specifications and Dimensions

Standard Outer Diameter Range

6mm to 50.8mm (1/4" to 2")

Wall Thickness Range

0.5mm to 4.0mm

Bend Radius

1.5D to 5D (where D is tube diameter)

Standard Length

Up to 24 meters (custom lengths available)

Performance Data: Temperature Resistance

Stainless steel U-bent tubes maintain structural integrity across a wide temperature range:

- Austenitic Grades (304, 316): Continuous service up to 870°C (1600°F)

- Ferritic Grades (430, 439): Continuous service up to 815°C (1500°F)

- Duplex Grades (2205, 2507): Continuous service up to 300°C (572°F)

- High-Temperature Alloys (310S, Inconel): Continuous service up to 1150°C (2100°F)

Stainless steel U-bent tubes Material

| Material Grade | Corrosion Resistance | Temperature Limit | Mechanical Strength | Cost Factor | Recommended Applications |

|---|---|---|---|---|---|

| 304/304L | Good | 870°C | Medium | Low | General purpose, food processing, mild chemical environments |

| 316/316L | Excellent | 870°C | Medium | Medium | Marine environments, chemical processing, pharmaceutical |

| 310S | Very Good | 1150°C | High | High | High-temperature furnaces, heat treatment equipment |

| Duplex 2205 | Excellent | 300°C | Very High | Medium-High | Offshore platforms, chemical tankers, desalination plants |

| Inconel 625 | Outstanding | 1150°C | Very High | Very High | Aerospace, nuclear reactors, severe corrosive environments |

Advantages of Stainless Steel U-Bent Tubes

Thermal Expansion Accommodation

The U-bend design naturally accommodates thermal expansion and contraction, reducing stress on tube sheets and supporting structures.

Enhanced Heat Transfer

Turbulence created by the U-bend improves heat transfer coefficients by up to 30% compared to straight tube configurations.

Compact Design

U-bent tubes allow for more heat transfer surface area in a smaller footprint, optimizing space utilization in heat exchangers.

Reduced Maintenance

Elimination of return bends and associated welds reduces potential leak points and maintenance requirements.

Manufacturing Process and Quality Control

Stainless steel U-bent tubes undergo a precise manufacturing process to ensure dimensional accuracy and material integrity:

Bending Process Parameters

- Bending Method: Cold bending using mandrel or rotary draw techniques

- Bend Tolerance: ±1° on bend angle, ±1.5mm on bend radius

- Wall Thinning: Controlled to less than 12% of original wall thickness

- Ovality Control: Maintained below 8% of nominal diameter

- Surface Finish: 0.4μm to 0.8μm Ra, with optional electropolishing

Industry Applications and Performance Data

| Industry | Common Materials | Service Conditions | Expected Service Life |

|---|---|---|---|

| Power Generation | TP304H, TP347H, T91, T22 | High pressure (1500-3000 psi), temperatures up to 600°C | 15-30 years |

| Chemical Processing | 316L, 317L, 904L, Hastelloy | Corrosive media, moderate temperatures (100-300°C) | 10-20 years |

| Oil & Gas Refining | 321, 347, Duplex 2205, Super Duplex | High chloride environments, moderate temperatures | 15-25 years |

| Food & Pharmaceutical | 304, 316, 316L (electropolished) | Sanitary conditions, CIP/SIP cycles | 10-15 years |

| HVAC & Refrigeration | 304, 316, Copper-Nickel | Moderate temperatures, water/brine service | 20-30 years |

Stainless steel U-bent tubes Testing and Certification

All stainless steel U-bent tubes undergo rigorous testing to ensure compliance with international standards:

Non-Destructive Testing

Eddy current, ultrasonic, hydrostatic, and pneumatic testing to detect flaws and ensure integrity.

Material Certification

Full traceability with Mill Test Certificates (MTC) verifying chemical composition and mechanical properties.

Dimensional Verification

Precision measurement of OD, wall thickness, bend radius, and ovality using calibrated instruments.

Surface Inspection

Visual examination and surface roughness measurement to ensure quality finish.

Industry Stainless steel U-bent tubes

Based on industry data from heat exchanger manufacturers:

- U-bent tube heat exchangers achieve heat transfer coefficients of 800-2000 W/m²K

- Properly designed U-bent tube bundles reduce pressure drop by 15-25% compared to hairpin configurations

- Material selection optimization can extend service life by 40-60% in corrosive environments

- U-bend designs reduce the number of tube-to-tubesheet joints by up to 50%, enhancing reliability

Stainless steel U-bent tubes represent a critical component in thermal management systems across multiple industries. Proper material selection, manufacturing quality, and application-specific design are essential for optimal performance and longevity in demanding service environments.