Selection & calculation of the twist flat-tube heat exchanger

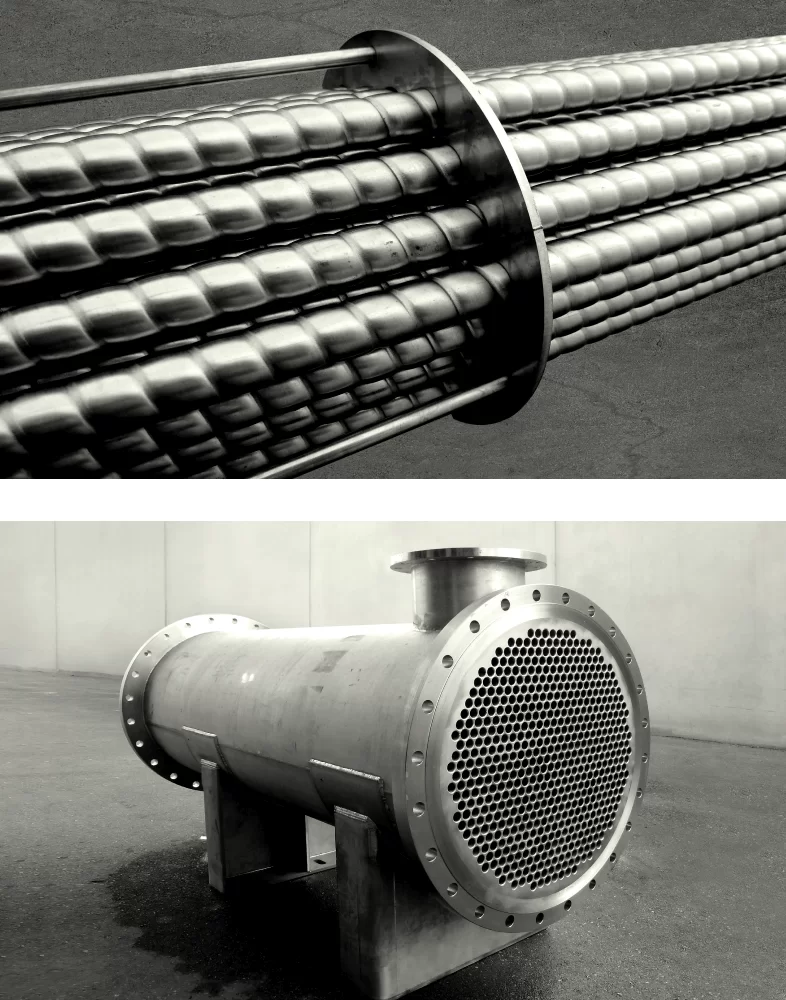

A twist flat-tube heat exchanger is a type of heat exchanger where the tubes are flat and arranged in a twisted or helical pattern within the heat exchanger shell. This design offers several advantages over traditional straight tube heat exchangers, including increased heat transfer area, enhanced heat transfer performance, and compact size.

Selection & calculation of the twist flat-tube heat exchanger

1. Define Requirements:

Determine the heat transfer rate, inlet and outlet temperatures of both fluids, allowable pressure drop, and any other specifications required for the heat exchanger.

2. Selection of Materials:

Choose appropriate materials for the heat exchanger tubes and shell based on factors such as compatibility with the fluids, corrosion resistance, and thermal conductivity.

3. Geometric Design:

- Tube Configuration: Decide on the arrangement of the flat tubes within the heat exchanger shell. In a twist flat-tube heat exchanger, the tubes are typically arranged in a helical pattern.

- Tube Dimensions: Determine the dimensions of the flat tubes including length, width, and thickness. These dimensions will influence the heat transfer area and pressure drop.

- Shell Dimensions: Determine the size and shape of the shell that will accommodate the flat tubes in the desired configuration.

4. Calculation of Heat Transfer Coefficients:

Calculate the heat transfer coefficients for both the inside and outside surfaces of the flat tubes. This involves considering factors such as fluid properties, flow rates, tube geometry, and flow regime.

5. Pressure Drop Calculation:

Calculate the pressure drop across the heat exchanger based on the fluid flow rates, geometry of the tubes, and flow characteristics.

6. Performance Evaluation:

Evaluate the performance of the heat exchanger based on the calculated heat transfer rate, pressure drop, and any other relevant factors. Compare the performance against the specified requirements to ensure they are met.

7. Optimization:

Iterate on the design parameters to optimize the heat exchanger for factors such as heat transfer efficiency, pressure drop, and cost.

8. Detailed Engineering:

Once the design is finalized, create detailed engineering drawings and specifications for fabrication and construction.