Lord Fin Tube--The types of finned tubes

The types of finned tubes

Finned tubes are used in a variety of applications, including heat exchangers, air conditioning systems, and power plants. They are designed to increase the surface area of the tube, which enhances heat transfer efficiency. There are several types of finned tubes, including:

1. Extruded finned tubes: These are created by extruding fins from a metal tube, typically aluminum or copper. The fins are integral to the tube and cannot be removed. These tubes are commonly used in air-cooled heat exchangers.

2. Embedded finned tubes: These tubes have fins that are embedded into the wall of the tube. They are typically made from carbon steel or stainless steel and are commonly used in heat exchangers in power plants and chemical plants.

3. Welded finned tubes: These tubes have fins that are welded onto the surface of the tube. They are commonly made from carbon steel, stainless steel, or aluminum and are used in a variety of applications, including air conditioning systems and heat exchangers.

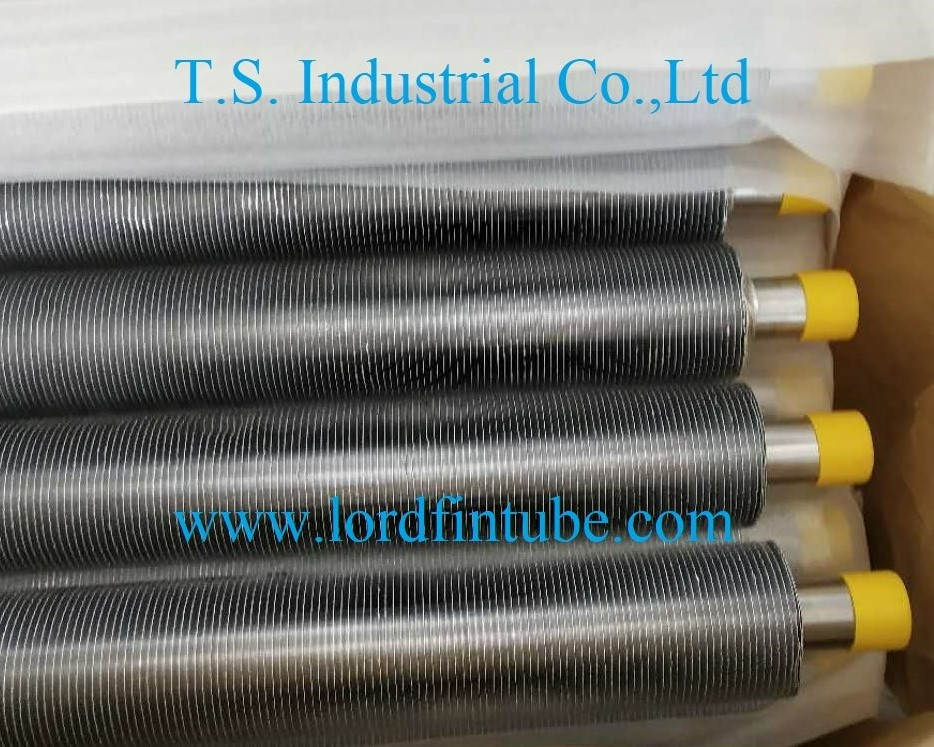

4. Spiral finned tubes: These tubes have fins that are wound around the outside of the tube in a spiral pattern. They are typically made from carbon steel, stainless steel, or aluminum and are commonly used in air-cooled heat exchangers.

4. L-foot finned tubes: These tubes have fins that are attached to the tube using L-shaped brackets. They are commonly used in air conditioning systems and heat exchangers.

5. G-fin tubes: These tubes have fins that are in the shape of a G, which provides a higher heat transfer coefficient than other types of finned tubes. They are commonly used in heat exchangers in the chemical and petrochemical industries.

6. HFW (High Frequency Welded) finned tubes: These tubes have fins that are welded onto the tube using a high frequency welding process. They are typically used in air-cooled heat exchangers, and their design can provide improved heat transfer efficiency compared to other types of finned tubes.

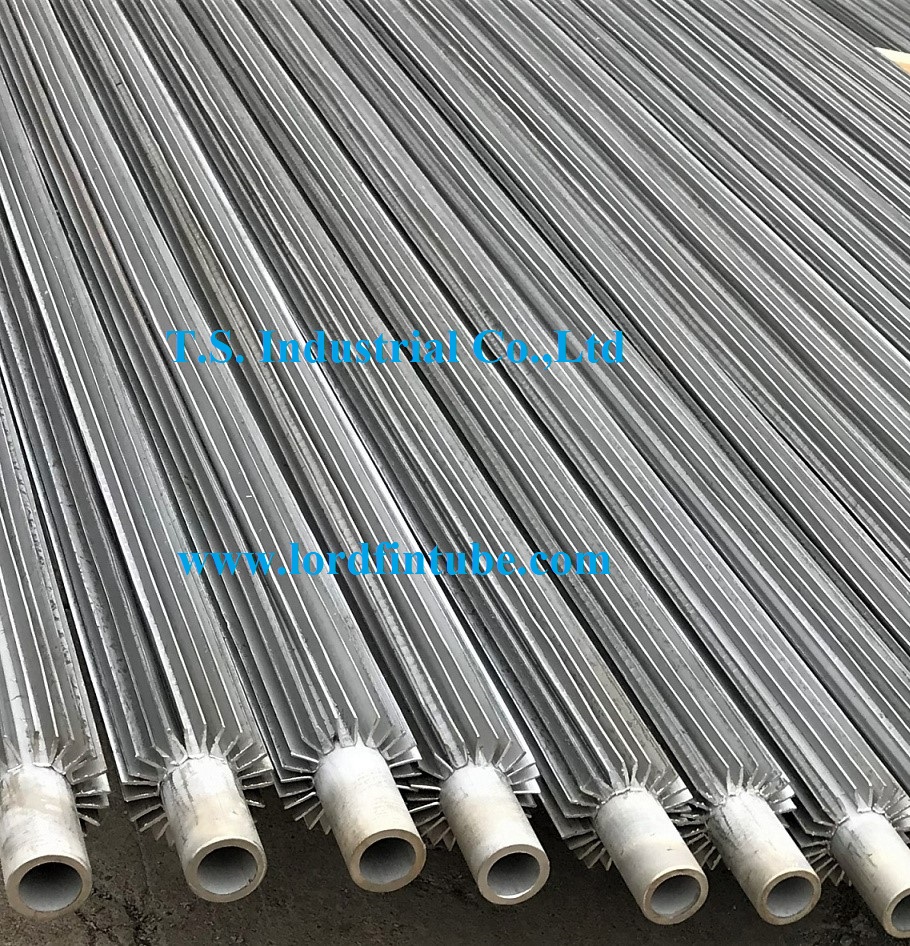

7. Longitudinal finned tubes: These tubes have fins that run along the length of the tube, rather than around the circumference. They are typically used in applications where space is limited, such as in compact heat exchangers.

8. Plate finned tubes: These tubes have fins that are attached to a plate that is then attached to the tube. The fins can be made from a variety of materials, including aluminum, copper, and stainless steel. Plate finned tubes are commonly used in heat exchangers for aerospace and aviation applications.

9. Low finned tubes: These tubes have fins that are shorter than other types of finned tubes, which reduces the distance between the fins and increases the heat transfer efficiency. They are commonly used in air conditioning systems and heat exchangers for the HVAC industry.

10. Knurled finned tubes: These tubes have fins that are knurled, which means they have a rough surface texture. The knurling can increase the surface area of the fin and improve heat transfer efficiency. Knurled finned tubes are commonly used in heat exchangers for the petrochemical industry.

These are some additional types of finned tubes that are commonly used in different applications. The choice of finned tube will depend on the specific requirements of the application, such as the operating conditions, the fluid being used, and the required heat transfer efficiency.