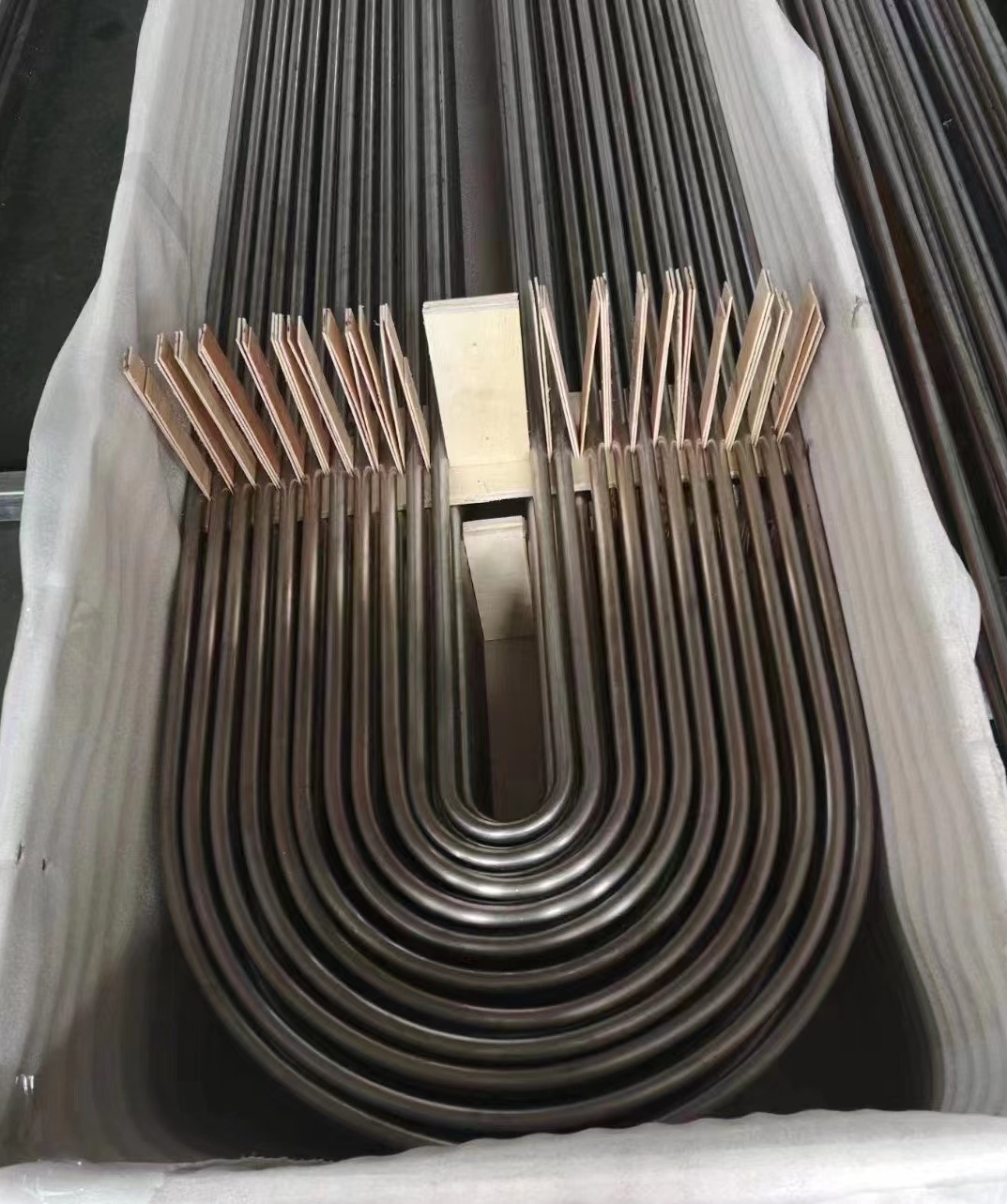

U bend heat exchanger tube ASME SA213 TP316L

What is a U Bend Heat Exchanger Tube ASME SA213 TP316L?

A U Bend Heat Exchanger Tube ASME SA213 TP316L is a seamless austenitic stainless steel tube designed for efficient heat transfer in various industrial applications. The U bend configuration maximizes surface area contact between fluids, enhancing thermal performance while maintaining a compact structure. Made from TP316L, the low carbon version of 316 stainless steel, it offers superior corrosion resistance, high-temperature strength, and excellent formability and weldability. This makes it ideal for use in environments like chemical processing plants, power generation facilities, and the oil and gas industry, where durability and reliability are paramount.

Introduction to ASME SA213 TP316L

ASME SA213 TP316L is a specification under the American Society of Mechanical Engineers (ASME) for seamless austenitic stainless steel tubing. TP316L refers to the low carbon version of 316 stainless steel, known for its exceptional corrosion resistance, high-temperature strength, and good formability and weldability. This makes it an ideal material for demanding industrial applications, including heat exchangers, chemical processing, power generation, and the oil and gas industry, where the materials ability to withstand harsh environments and maintain structural integrity is crucial.

Why Choose U Bend Heat Exchanger Tube ASME SA213 TP316L?

Efficient Heat Transfer

The U bend design optimizes the heat transfer process. By bending the fluid path into a U shape, the residence time of the fluid inside the tube is increased, enhancing heat exchange efficiency. This design is especially suitable for applications requiring efficient heat transfer in compact spaces.

Reduced Pressure Drop

The U bend configuration helps reduce pressure drop during fluid flow, increasing overall system efficiency. Lower pressure drop means lower pumping costs and higher system performance.

Compact Structure

The U bend design allows for maximum heat transfer efficiency in compact spaces. Its flexible installation options and compact structure make it an ideal choice for various industrial applications.

Superior Corrosion Resistance

One of the standout features of TP316L stainless steel is its exceptional resistance to corrosion. The low carbon content in TP316L helps prevent carbide precipitation during welding, which can lead to intergranular corrosion. This makes it suitable for use in environments where exposure to corrosive substances is a concern, such as in chemical processing plants and marine environments.

High-Temperature Performance

TP316L maintains its strength and integrity even at elevated temperatures. This makes the U bend heat exchanger tube particularly useful in applications where high-temperature fluids are involved. The materials ability to withstand heat without compromising its mechanical properties ensures longevity and reliability.

Good Formability and Weldability

TP316L has good formability and weldability, making it suitable for manufacturing complex shapes in heat exchanger tubes. This material is easy to process and can meet various industrial applications diverse needs.

Processing Considerations for U Bend Heat Exchanger Tube ASME SA213 TP316L

Precise Bending

Precision in bending is crucial when processing U bend tubes. It is essential to ensure that each bends angle and radius meet the design requirements to maintain the heat exchangers performance and efficiency.

Welding Quality

Welding is a critical step in the manufacturing process of U bend tubes. Each step in the welding process must meet the standards to avoid defects and degradation of material properties.

Surface Treatment

To enhance corrosion resistance and extend service life, U bend tubes typically undergo surface treatment after processing. This includes polishing and passivation to ensure smooth and corrosion-resistant inner and outer surfaces.

Applications of U Bend Heat Exchanger Tube ASME SA213 TP316L

Chemical Processing

In chemical plants, materials must resist aggressive chemicals and high temperatures. The U bend heat exchanger tube ASME SA213 TP316L is widely used in these environments to ensure efficient heat transfer and prevent contamination. Its superior corrosion resistance and high-temperature performance make it an ideal choice for the chemical industry.

Power Generation

Power plants rely on efficient heat exchangers to maintain optimal performance. The high-temperature tolerance and durability of TP316L make it ideal for use in boiler tubes and other heat exchange equipment in power generation facilities. In these applications, U bend heat exchanger tubes can operate stably under high temperatures and pressures, ensuring the reliability and efficiency of power generation equipment.

Oil and Gas Industry

In the oil and gas industry, equipment is exposed to harsh conditions and corrosive substances. The U bend heat exchanger tube ASME SA213 TP316L provides reliable performance. It is commonly used in refineries, offshore platforms, and petrochemical plants. Its superior corrosion resistance and mechanical properties enable it to withstand the demanding environments in these industries.

The U bend heat exchanger tube ASME SA213 TP316L is a versatile and robust solution for various industrial applications. Its superior corrosion resistance, high-temperature performance, and efficient design make it an essential component in heat transfer systems. Investing in these high-quality tubes ensures enhanced efficiency, longevity, and cost-effectiveness in demanding environments.

U bend heat exchanger tube ASME SA213 TP316L