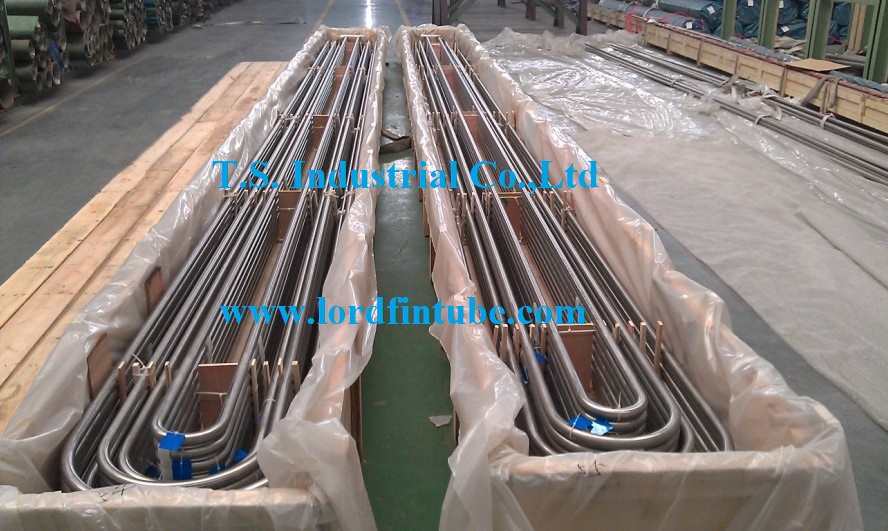

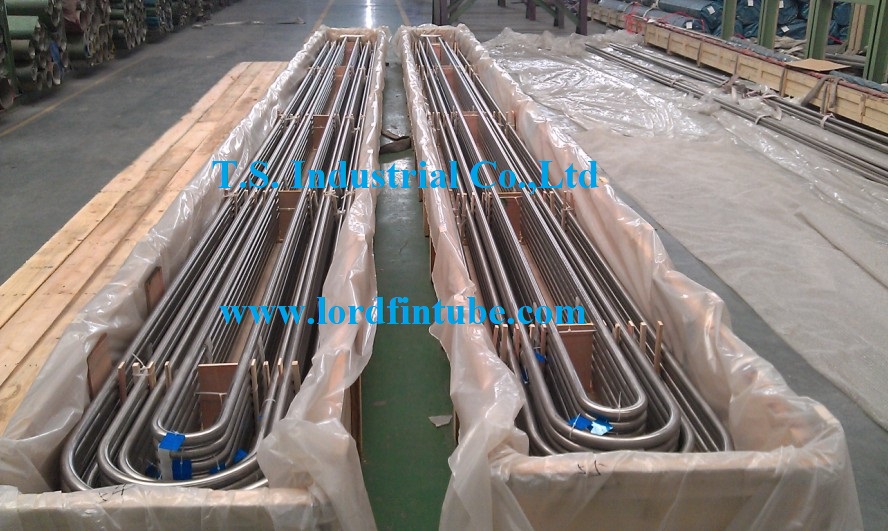

Products Description

The ASTM B444 standard outlines the specifications for pipes and tubes made from nickel-chromium-molybdenum-columbium alloys (UNS N06625 and UNS N06852) as well as nickel-chromium-molybdenum-silicon alloy (UNS N06219). These pipes and tubes are provided in a cold-worked seamless form with a diameter of 3 inches. The overall requirements for these pipes and tubes are detailed in Specification B829. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Specification for Seamless Nickel and nickel Alloy Condenser and Heat-Exchanger tubes

U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Technical Delivery Conditions (TDC)

Material furnished under this specification shall conform to the applicable requirements of Specification B829 unless otherwise provided herein.

1. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 General requirement,

1.1 Wall thickness shall be as specified in PR or PO (i.e. minimum ) after construction.

1.2 All Tube material shall be free of rust, dirt, pits, gouges, crevices.

1.3 Product Analysis shall be reported in MTC.

1.4 Each tube shall be formed from a single length without circumferential welds.

1.5 All tubes shall be in annealed condition.

2. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Non-destructive Testing,

2.1 All tubes shall be subjected to Eddy current testing as per ASTM E 571 & Annexture-I.

2.2 Visual inspection of the U-bends after the bending in order to verify that there are no flaws such as folds, shrinks, friction signs or material tears, flattening.

3. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Marking and Certification,

3.1 Material marking fluid shall be compatible with inconel steel, e.g. they shall not contain chlorides, zinc, sulphur or other detrimental component.

3.2 Markings shall be protected from erosion, wear, or other events that may render them unreadable.

3.3 Material test reports shall be submitted conforming to mandatory certification requirements as per material specification and this TDC.

3.4 Material certificate shall contain all the data relating to condition of supply, tests, examinations.

4. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Additional Clients General Requirement,

4.1 The country of origin for items (finished product) and the raw materials from which the items are formed shall be traceable from the certification and/or marking.

5. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Tolerances

Permissible variations for material specified as small diameter and light-wall tube (converter size) shall conform to the permissible variations prescribed in Table X1.1 and Table X1.2.

5.1 Tube wall thinning in the bends shall not exceed nominal 3% of original tube wall thickness.

5.2 Flattening at the bends shall not exceed 10% nominal OD of straight portion tube for U-tubes.

5.3 Mock-up result shall be checked at minimum bend radius ( 0,30,60,90 Deg) for thinning and flattening.

6. U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Heat Treatment for U-bend portion,

6.1 After bending all tubes shall be subjected to heat treatment at 871˚C min. followed by rapid cooling.

6.2 Heat treatment shall be completed by electric resistance or furnace methods.Open Flame heat treatment is not permitted.

6.3 For electric resistance or induction heating, the heat-treated portion of the U-bend shall extend at Least 300 mm beyond the tangent point. For furnace heating, the heat treatment shall extend at least 600 mm beyond the tangent point.

6.4 After heat treatment all tube shall receive a descaling treatment. All mill scale will be removed.

6.5 During treatment mentioned in Clause 6.1, Inside surface of tube shall be protected by inert gas atomsphere.

7. U-bend Type Seamless tubes SB-444 UNS N066257 U-bend Type Seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 Annexture-I NDE requirements for Tubes

7.1 If pierced mother hollow is used then UT of mother hollow shall be carry out as per Article 4 of ASME Sec V,Edition 65. Acceptance criteria for UT shall be as per Appendix-12 of ASME SEC VIII Div.1,65 Edition.

7.2 If extrudded mother hollow is used than requirement mentioned in Clause 2.1 is not applicable.

7.3 Eddy current testing on all tube shall be carried out as per Table-1 and calibration sample for eddy current testing shall be as per Table 2. Eddy current testing shall be performed on all tubes before bending of tube. Table-1

7.4 Both end of tube shall be cut, to remove "Blind Area" after testing of tube. Refer table 3. Table-3 Tube Length that has to be cut after ECT

7.5 Hydro test carry out for all tubes, for minimum holding time of 2 minutes.Maximum chloride content of water shall be 30 ppm.

7.6 Digital pressure gauge shall required for hydro test.

7.7 U- bends on both side shall be subjected to dye penetrant examination (U portion + 300mm straight length). Crack or any relevent linear indication shall result in rejection of tube as per ASME Sec. VIII Div.1 App. 8.

7.8 Any non relevant linear indication on U bend portion shall be polished for removal of and eliminate possibility relevant indication.

7.9 DP testing shall be carried out on both the ends of tube, from out side upto 2 inch and from Inside upto avilable accessible area, after tubes are cut to length.Acceptance criteria as per ASME Sec. VIII Div.1 App. 8.

7.10 ECT shall be witnessed by person who has valid ECT level 2 certificate & All ECT report shall be certified by ECT level 2 person only.

7.11 For ID and OD Eddy current Testing, ECT charts/reports shall be submitted in soft copy along with Material Test Certificate of tube.

7.12 The frequency of checking the calibration shall be at least every four hours, but also whenever there is an equipment team operator team change over and at the start and end of testing.

The chemical composition of U-bend type seamless tubes SB-444 / SB-444M UNS N06625 Grade 1 refers to a specific type of alloy and its composition. UNS N06625 is a common designation for Inconel 625, which is a nickel-chromium-molybdenum alloy known for its high strength and excellent corrosion resistance, particularly in high-temperature environments. The chemical composition of Inconel 625 Grade 1 typically includes the following elements:

8. U-bend Type Seamless tubes SB-444 UNS N066257 Chemical composition

8.1. Nickel (Ni): Around 58.0% min

8.2. Chromium (Cr): 20.0 - 23.0%

8.3. Molybdenum (Mo): 8.0 - 10.0%

8.4. Iron (Fe): 5.0% max

8.5. Niobium (Nb) + Tantalum (Ta): 3.15 - 4.15%

8.6. Carbon (C): 0.010% max

8.7. Manganese (Mn): 0.50% max

8.8. Silicon (Si): 0.50% max

8.9. Phosphorus (P): 0.015% max

8.10. Sulfur (S): 0.015% max

8.11. Aluminum (Al): 0.40% max

8.12. Titanium (Ti): 0.40% max