What Is Tube Sheet In Heat Exchanger?

What Is Tube Sheet In Heat Exchanger?

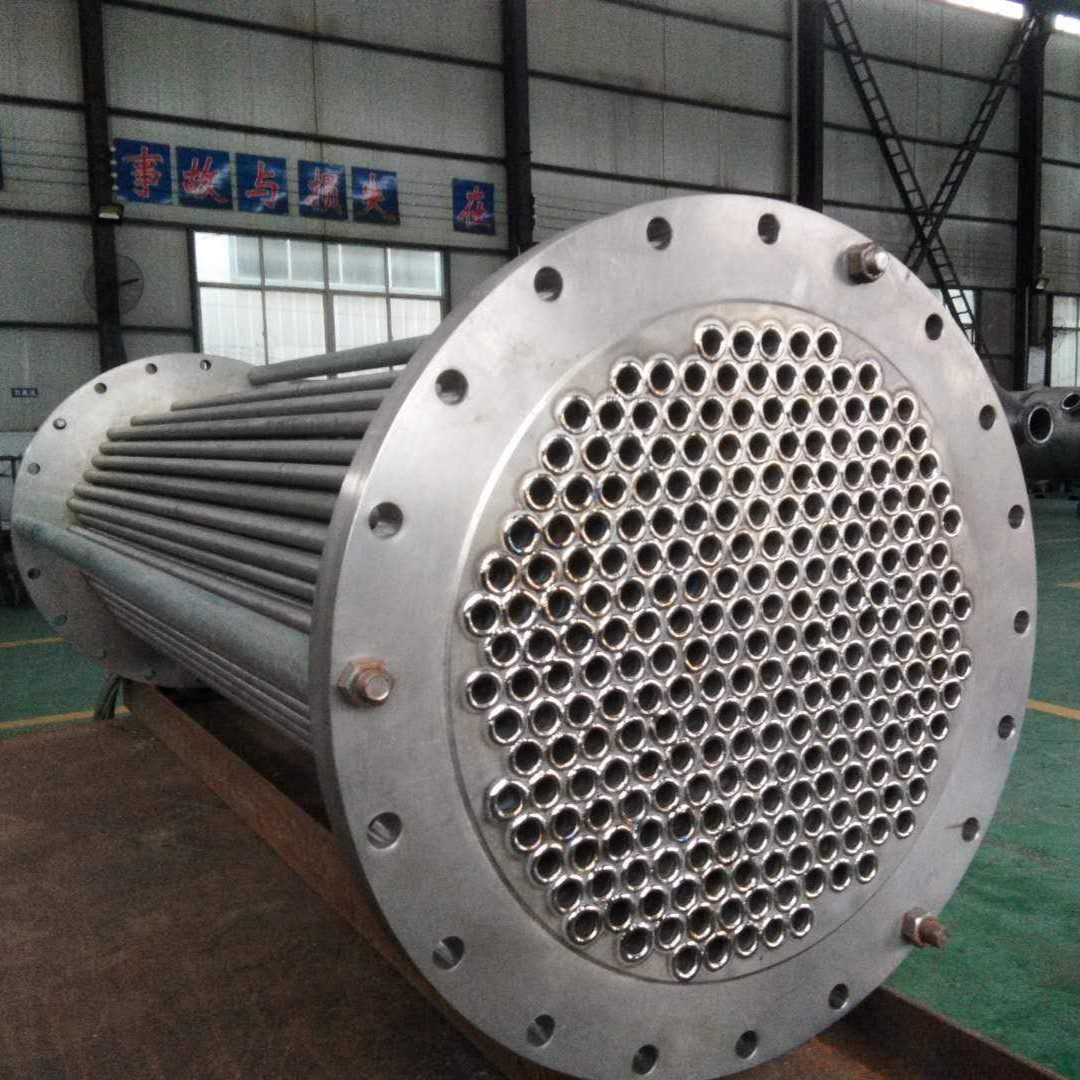

Tube sheets are critical components in shell and tube heat exchangers, serving as structural elements that support and separate tubes while facilitating efficient heat transfer between fluid streams. These precision-engineered plates play a vital role in the reliability and performance of heat exchange systems across various industries.

Function and Importance of Tube Sheets

Tube sheets perform several essential functions in heat exchangers:

- Provide structural support for tube bundles

- Maintain proper tube alignment and spacing

- Create a barrier between shell-side and tube-side fluids

- Facilitate efficient heat transfer between fluid streams

- Allow for proper distribution of fluids within the exchanger

Tube Sheet Design Specifications

Tube sheet design varies based on operating conditions, with key parameters including:

| Parameter | Range | Standard Values |

|---|---|---|

| Tube Pattern | Triangular, Square, Rotated Square | Triangular (30°, 60°), Square (90°) |

| Tube Pitch Ratio | 1.25 - 1.5 | 1.25 (common), 1.33 (frequent), 1.5 (minimum) |

| Tube Hole Tolerance | ±0.005 inches | ±0.002 - ±0.005 inches |

| Ligament Efficiency | 15% - 45% | 25% - 35% (typical) |

| Thickness Range | 1" - 24" | 2" - 12" (most common) |

Tube Sheet Materials

Material selection depends on corrosion resistance, thermal conductivity, and mechanical strength requirements:

| Material | Advantages | Limitations | Typical Applications |

|---|---|---|---|

| Carbon Steel | Cost-effective, good mechanical strength | Poor corrosion resistance | Non-corrosive environments, oil and gas |

| Stainless Steel (304/316) | Excellent corrosion resistance, good strength | Higher cost, potential for chloride stress corrosion | Chemical processing, food and beverage |

| Brass | Good thermal conductivity, reasonable corrosion resistance | Not suitable for ammonia environments | Marine applications, low-pressure steam |

| Titanium | Exceptional corrosion resistance, high strength-to-weight ratio | High cost, difficult to machine | Seawater cooling, chemical processing |

| Clad Materials | Cost-effective corrosion protection | Fabrication challenges, potential for delamination | High-pressure corrosive environments |

Tube Sheet Manufacturing Process

The manufacturing of tube sheets involves several critical steps:

- Material Selection: Choosing appropriate material based on service conditions

- Cutting and Forming: Precision cutting to required dimensions

- Drilling: Accurate hole drilling with strict tolerances

- Counterboring: Creating recesses for expanded tube joints

- Facing: Machining surfaces to ensure flatness

- Grooving: Cutting grooves for sealing elements when required

Industry Insight: Modern CNC-controlled drilling machines can achieve hole position accuracies within ±0.001 inches, which is critical for proper tube installation and performance.

Tube Attachment Methods

Several techniques are used to secure tubes to tube sheets:

| Method | Process | Strength | Leak Prevention | Applications |

|---|---|---|---|---|

| Expansion | Mechanical or hydraulic tube expansion | Medium | Good | Low to medium pressure applications |

| Welding | Fusion welding of tube to sheet | High | Excellent | High pressure/temperature services |

| Explosive | Using controlled explosive force | High | Excellent | Hard-to-reach areas, special alloys |

| Rolling & Welding | Combination of expansion and welding | Very High | Superior | Critical services, nuclear applications |

Industry Standards and Codes

Tube sheet design and manufacturing follow established international standards:

- ASME Boiler and Pressure Vessel Code, Section VIII

- TEMA Standards (Tubular Exchanger Manufacturers Association)

- API 660 (Shell-and-Tube Heat Exchangers)

- EN 13445 (Unfired Pressure Vessels)

Performance Data and Statistics

| Failure Mode | Frequency (%) | Primary Causes | Prevention Methods |

|---|---|---|---|

| Corrosion | 42% | Improper material selection, corrosive environment | Material upgrade, protective coatings |

| Stress Corrosion Cracking | 23% | Tensile stress + corrosive environment | Stress relief, material change |

| Erosion | 15% | High-velocity fluids, particulate matter | Flow control, erosion-resistant materials |

| Fatigue | 12% | Cyclic pressure, vibration | Design improvements, support addition |

| Manufacturing Defects | 8% | Improper drilling, poor welds | Quality control, inspection protocols |

Maintenance and Inspection

Regular inspection and maintenance are crucial for tube sheet longevity:

- Visual inspection for corrosion and cracking

- Non-destructive testing (NDT) methods:

- Dye penetrant testing

- Magnetic particle inspection

- Ultrasonic testing

- Eddy current testing

- Thickness measurements

- Tube joint integrity checks

Maintenance Tip: According to industry data, regular inspection and maintenance can extend tube sheet life by 40-60% and reduce unexpected downtime by up to 70%.

Tube sheets

Tube sheets are fundamental components in heat exchanger design, directly impacting equipment performance, reliability, and service life. Proper material selection, precision manufacturing, appropriate tube attachment methods, and regular maintenance are all critical factors in ensuring optimal tube sheet performance. Understanding the technical aspects of tube sheet design and function enables engineers to specify and maintain heat exchangers that meet specific operational requirements while maximizing efficiency and minimizing life-cycle costs.

As heat exchanger technology continues to evolve, tube sheet design and manufacturing processes are also advancing, with improvements in materials, fabrication techniques, and inspection methods contributing to enhanced performance and reliability in increasingly demanding applications.