2Cr13 stainless steel forged plate

What is 2Cr13 stainless steel forged plate?

2Cr13 belongs to martensitic stainless steel. 2Cr13 is corresponding to the American Standard 420, which belongs to martensitic stainless steel: chemical composition: C: 0.16-0.25; Si: ≤ 1.00; Mn: ≤ 1.00; P: ≤ 0.040; s: ≤ 0.030; Ni: ≤ 0.6; Cr: 12.00-14.00

For large ring forgings, it has poor thermal conductivity and is sensitive to surface cracks. It is easy to crack during heating and forging, resulting in defects such as inclusions and cracks inside. Therefore, it is necessary to formulate a reasonable forging process for 2Cr13 large ring forgings, and combined with the actual production situation, the process flow has been effectively verified.

2Cr13 physical properties: 2Cr13 belongs to martensitic stainless steel, mainly used in the manufacture of mechanical parts that withstand high stress and require corrosion resistance and wear resistance, and are also widely used in paper industry, food industry, tableware and medical equipment. ⑶ Supply status: annealing treatment after forging to prepare for subsequent quenching and tempering.

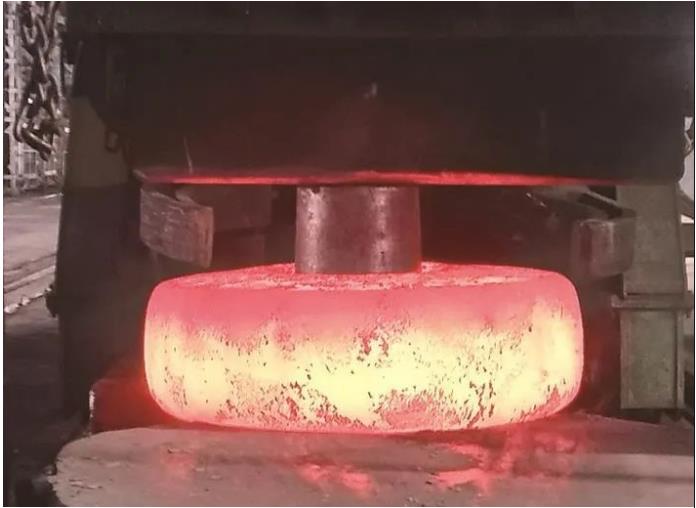

2Cr13 stainless steel forged plate forging process:

In view of the characteristics of 2Cr13 martensitic stainless steel, its forging process is as follows: steel ingot→primary heating→cutting water riser→second heating→upsetting and leveling punching→three heating→ring rolling→annealing→rough turning→flaw detection→ Hit hardness→package.

2Cr13 stainless steel forged plate UT testing:

Roughly turn the end face of the annealed ring to ensure that the roughness is Ra12.5μm, conduct 100% UT flaw detection on the end face, and the flaw detection level meets the requirements.