ASTM B359/B359M Copper-Alloy Tubes With Integral Fins

ASTM B359/B359M Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

1. ASTM B359/B359M Scope

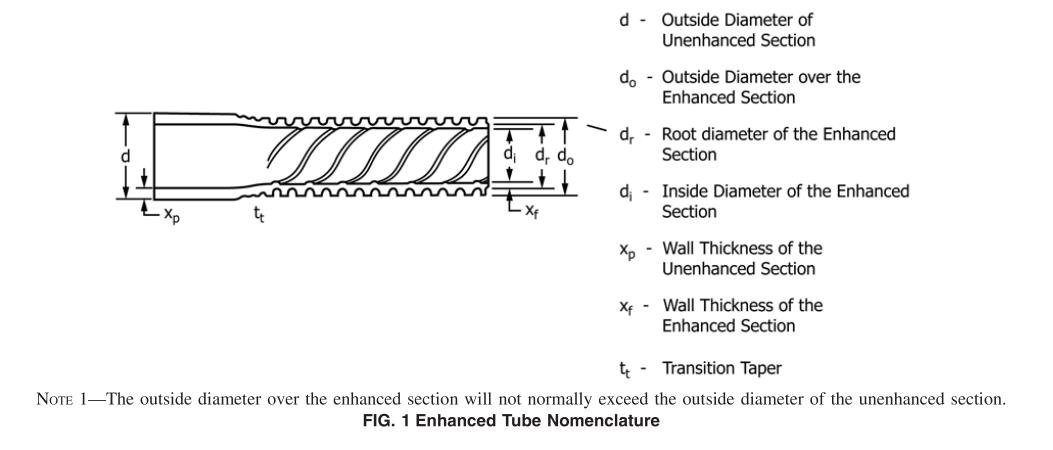

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or internal surface, or both, has been modified by a cold forming process to produce an integral enhanced surface for improved heat transfer.

1.2 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.3 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy UNS No. Type of Metal

C10100 Oxygen-free electronic

C10200 Oxygen-free without residual deoxidants

C10300 Oxygen-free, extra low phosphorus

C10800 Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus

C12200 DHP, Phosphorized, high residual phosphorus

C14200 DPA Phosphorized arsenical

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty Metal Types B,

C44400 C, and C44550 D

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel Type A

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

1.4 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.5 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced only to the inch-pound system of this specification.

1.6 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility ofthe user of this standard to establish appropriate safety and health practices and determine the applicability ofregulatory limitations prior to use. Some specific hazards statements are given in Sections 1, 12 and 18.

1.7 (Warning—Mercury has been designated by many regulatory agencies as a hazardous material that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Safety Data Sheet (SDS) for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.)

2. ASTM B359/B359M Referenced Documents

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B170 Specification for Oxygen-Free Electrolytic Copper Refinery Shapes

B224 Classification of Coppers

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

B858 Test Method forAmmonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

B900 Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

B968/B968M Test Method for Flattening of Copper and Copper-Alloy Pipe and Tube

D4727/D4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes E3 Guide for Preparation of Metallographic Specimens

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and CopperAlloys (Photometric Methods) (Withdrawn 2010)

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper Chromium Alloys (Withdrawn 2010) 4

E243 Practice for Electromagnetic (Eddy Current) Examination of Copper and Copper Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

E2575 Test Method for Determination of Oxygen in Copper and Copper Alloys

3. ASTM B359/B359M General Requirements

3.1 Product described by this specification shall typically be furnished with unenhanced ends, but may be furnished withenhanced ends or stripped ends from which the O.D. enhancement has been removed by machining.

3.1.1 The enhanced sections of the tube in the as-fabricated temper are in the cold-worked condition produced by the enhancing operation.

3.1.2 The unenhanced sections of the tube shall be in the annealed or light drawn temper, and shall be suitable for rolling-in operations.

4. ASTM B359/B359M Terminology

4.1 For the definitions of terms related to copper and copper alloys, refer to Terminology B846.

4.2 Definitions ofTerms Specific to This Standard:

4.2.1 tube condenser, n—see tube, heat exchanger in Terminology B846.

5. ASTM B359/B359M Ordering Information

5.1 Include the following information when placing orders under this specification:

5.1.1 ASTM designation and year of issue,

5.1.2 Copper or CopperAlloy UNS No. designation (see 1.3 and Section 7),

5.1.3 Temper (see Section 8),

5.1.4 Dimensions: diameter, wall thickness, length and location of unenhanced surfaces and total tube length. Configuration of enhanced surfaces shall be as agreed upon between

the manufacturer and the purchaser.

5.1.5 Whether the product is to be subsequently welded for UNS Alloy C72200, UNS Alloys C70620 and C71520 are welding grades of C70600 and C71500,

5.1.6 Quantity

5.1.7 If product is for the U.S. government.

5.2 The following options are available and shall be specified at the time of placing the order, when required:

5.2.1 When heat identification or traceability is required,

5.2.2 When tubes are for Boiler and Pressure Vessel code application, which should then be ordered according to ASME SB 359,

5.2.3 Flattening test (see 11.2),

5.2.4 Certification (see Section 22), when required,

5.2.5 Mill test report (see Section 23), when required, and

5.2.6 Stress relief annealing (see 9.4), when required.

5.3 In addition, when material is purchased for agencies of the U.S. government, it shall conform to the requirements specified in the Supplementary Requirements section, when specified in the contract or purchase order.

6. ASTM B359/B359M Materials and Manufacture

6.1 Materials:

6.1.1 The material of manufacture shall be of such quality and purity that the finished product shall have the properties and characteristics prescribed in this specification for the applicable alloy and temper.

6.2 Manufacture:

6.2.1 The seamless copper and copper alloy tubing shall have the internal or external surface, or both, modified by a cold forming process to produce an integral enhanced surface for improved heat transfer.

6.2.2 The cut ends of the tubes shall be deburred.

6.2.3 Due to the discontinuous nature of the processing of castings into wrought products, it is not practical to identify specific casting analysis with a specific quantity of finished material.

6.2.4 When heat identification is required, the purchaser shall specify the details desired in the purchase order or contract.

Standard ASTM B359/B359M download Links