Lord Fin Tube--Economizer with Finned Tube

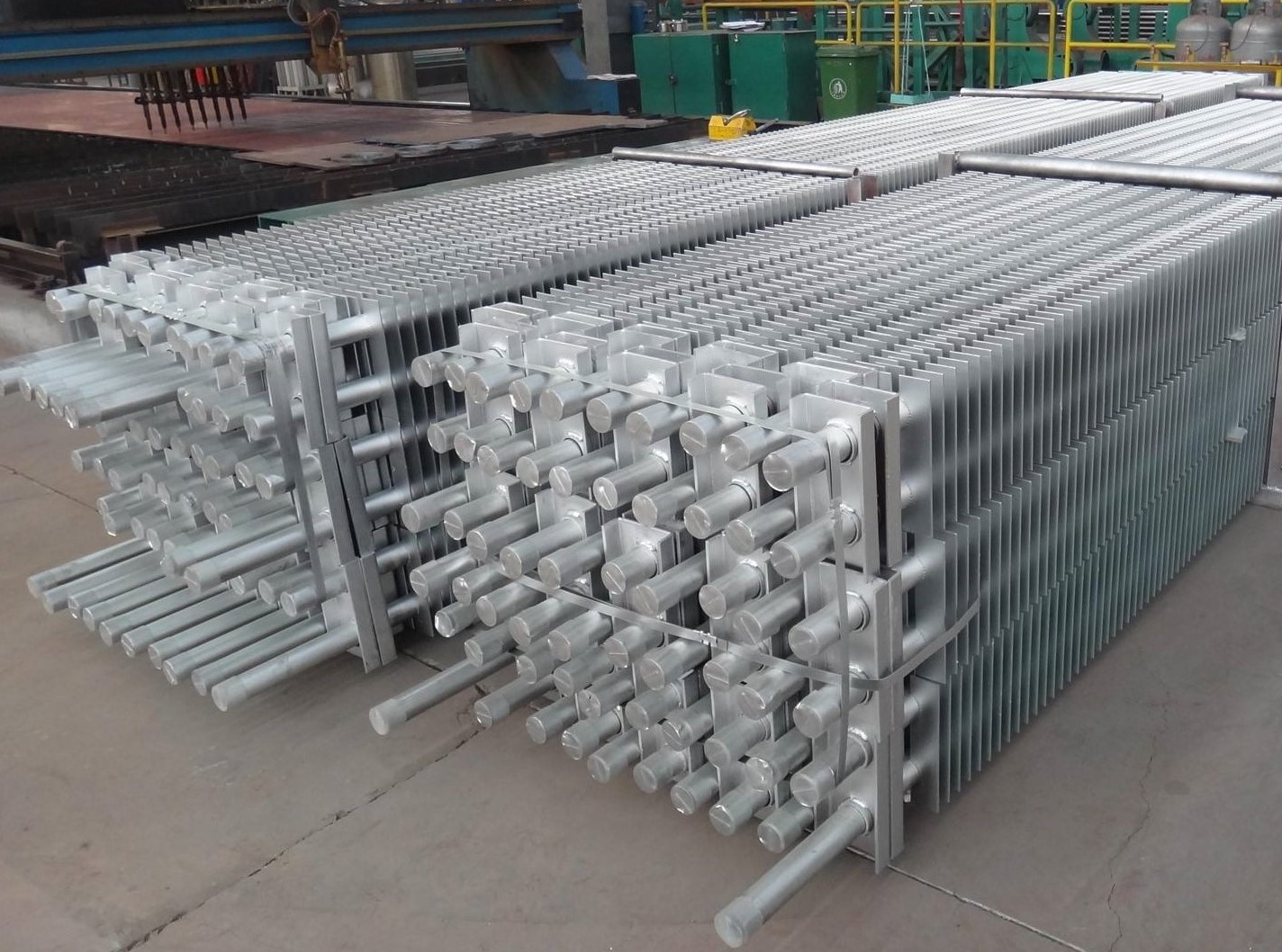

Economizer with finned tube

An economizer with finned tubes is a type of heat exchanger used in industrial and commercial boilers to recover heat from the flue gas before it is released into the atmosphere. The economizer uses finned tubes to increase the heat transfer surface area, which improves heat recovery efficiency and reduces fuel consumption.

The basic design of an economizer with finned tubes involves a bundle of tubes that are arranged in parallel and connected by headers. The hot flue gas from the boiler passes over the outside of the finned tubes, while the colder feedwater passes through the inside of the tubes. As the flue gas passes over the finned tubes, heat is transferred from the gas to the tubes, which heats up the feedwater.

The finned tubes used in economizers have fins attached to the outside of the tubes, which increase the heat transfer surface area and improve heat transfer efficiency. The fins can be either rectangular or triangular in shape, and can be arranged in various configurations, such as in-line, staggered or wavy.

Economizers with finned tubes are commonly used in industrial and commercial boilers, where they can help to reduce fuel consumption and operating costs, as well as reduce greenhouse gas emissions. The efficiency of an economizer with finned tubes will depend on factors such as the design of the heat exchanger, the temperature difference between the flue gas and the feedwater, and the flow rates of the fluids.

What kind of finned tube used in economizer?

The type of finned tube used in an economizer depends on the specific application and design requirements. However, there are several common types of finned tubes that are used in economizers:

1. Extruded finned tubes: These finned tubes are made by extruding fins from the wall of a plain tube. The fins are typically rectangular in shape and are closely spaced to maximize the heat transfer surface area.

2. Welded finned tubes: These finned tubes are made by welding fins onto the surface of a plain tube. The fins can be either rectangular or circular in shape and are spaced at a predetermined distance to optimize the heat transfer surface area.

3. L-finned tubes: These finned tubes have fins that are bent at a right angle to the tube wall, forming an L-shape. The L-fins provide a larger heat transfer surface area than rectangular fins, which improves the heat recovery efficiency.

4. G-finned tubes: These finned tubes have fins that are bent into a G-shape, which provides a larger heat transfer surface area than L-finned tubes. G-finned tubes are commonly used in applications where a high heat transfer rate is required.

5. H-finned tubes: These finned tubes have fins that are bent into an H-shape, which provides an even larger heat transfer surface area than G-finned tubes. H-finned tubes are commonly used in applications where a very high heat transfer rate is required.

Overall, the type of finned tube used in an economizer will depend on factors such as the operating conditions, the heat transfer requirements, and the available space for the heat exchanger. The final decision should be based on a thorough analysis of the specific application and design requirements.