High Frequency Welding of Spiral Finned Tube

High Frequency Welding of Spiral Finned Tube Introduction

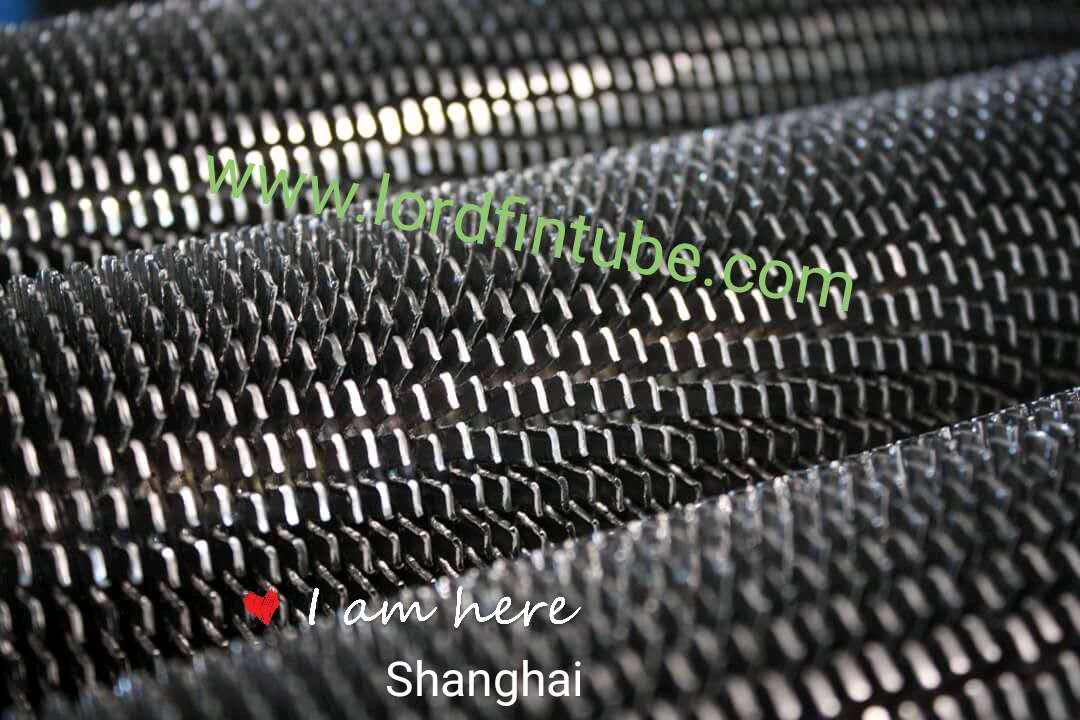

High Frequency Welding (HFW) is a crucial technique in the manufacturing of spiral finned tubes. These tubes are extensively used in heat exchangers due to their enhanced heat transfer capabilities. This article aims to provide a comprehensive overview of the HFW process for spiral finned tubes, including its principles, applications, advantages, and relevant data.

Principles of High Frequency Welding

High Frequency Welding involves the use of high-frequency electrical currents to fuse materials together. This process is characterized by the following steps:

Induction Heating: High-frequency currents are induced into the materials, generating heat due to electrical resistance.

Pressure Application: The heated materials are pressed together, causing the surfaces to bond.

Cooling: The welded joint is cooled to solidify the bond.

Applications of Spiral Finned Tubes

Spiral finned tubes are used in various industries, including:

Power Generation: Boilers and heat recovery steam generators.

Petrochemical: Heat exchangers and condensers.

HVAC: Air conditioning and refrigeration units.

Automotive: Radiators and exhaust gas recirculation coolers.

Advantages of High Frequency Welding for Spiral Finned Tubes

Enhanced Efficiency: Provides superior heat transfer due to the increased surface area of the fins.

Durability: Produces strong and reliable joints capable of withstanding high pressure and temperature.

Cost-Effectiveness: Reduces manufacturing costs by minimizing material waste and processing time.

Versatility: Applicable to a wide range of materials and tube sizes.

Technical Data and Performance Metrics

Below is a table presenting key technical data for spiral finned tubes produced using high-frequency welding:

|

Parameter |

Value |

|

Tube Material |

Carbon Steel, Stainless Steel, Alloy Steel |

|

Fin Material |

Aluminum, Copper, Stainless Steel |

|

Fin Height |

5 mm - 30 mm |

|

Fin Thickness |

0.3 mm - 1.5 mm |

|

Tube Diameter |

15 mm - 219 mm |

|

Welding Frequency |

150 kHz - 450 kHz |

|

Heat Transfer Coefficient |

Up to 3000 W/m²K |

|

Operating Temperature Range |

-50°C to +800°C |

|

Operating Pressure Range |

Up to 35 MPa |

HFW Spiral Finned Tube Manufacturing Process

Material Preparation: Tubes and fins are cleaned and prepped for welding. The materials are typically chosen based on the specific requirements of the application.

Tube Feeding: The tube is fed into the welding machine, where it is precisely positioned for the finning process.

Fin Forming and Positioning: Fins are formed from a continuous strip and wrapped helically around the tube. They are positioned accurately using a finning head.

High-Frequency Induction Heating: High-frequency current is applied to heat the tube and the root of the fins to a temperature where the material becomes plastic.

Welding: The heated materials are then pressed together using mechanical force, forming a metallurgical bond between the fin and the tube.

Cooling: The welded joint is immediately cooled to ensure the bond solidifies quickly and to prevent any deformation or oxidation.

Quality Inspection: Weld joints are inspected for defects using non-destructive testing methods such as ultrasonic testing or eddy current testing to ensure the integrity of the weld.

Cutting and Finishing: The finned tubes are cut to the desired length and subjected to surface treatments if necessary, such as galvanizing or coating to enhance corrosion resistance.

High Frequency Welding of Spiral Finned Tube Quality Control and Standards

1. Material Standards:

ASTM A106/A213: Specifications for seamless carbon steel and alloy tubes.

ASTM A249/A269: Specifications for welded/seamless austenitic steel boiler, superheater, heat exchanger, and condenser tubes.

ASTM B111/B111M: Specifications for copper and copper-alloy seamless condenser and heat exchanger tubes.

2. Manufacturing Standards:

ASME Section VIII: Boiler and pressure vessel code.

EN 10204: Metallic products - Types of inspection documents.

3. Quality Management Systems:

ISO 9001: Quality management systems - Requirements. This standard ensures that manufacturers maintain consistent quality in their processes.

4. Non-Destructive Testing (NDT):

Ultrasonic Testing (UT): Used to detect internal flaws and measure wall thickness.

Eddy Current Testing (ECT): Used for detecting surface and near-surface defects.

Radiographic Testing (RT): Used to examine the internal structure of the welds.

5. Dimensional and Visual Inspection:

Dimensional Checks: Ensures that the finned tubes meet specified dimensions, including fin height, spacing, and tube diameter.

Visual Inspection: Inspects for surface defects such as cracks, porosity, and incomplete welds.

6. Mechanical Testing:

Tensile Testing: Assesses the tensile strength and ductility of the welded joint.

Hardness Testing: Measures the hardness of the weld area to ensure it meets required specifications.

High Frequency Welding of spiral finned tubes are a highly efficient and reliable method used across various industries to enhance heat transfer. By understanding the principles, applications, advantages, and technical data associated with this process, manufacturers can produce high-quality, durable, and cost-effective spiral finned tubes.

HFW Spiral Finned Tube References

ASTM International. (2020). Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service.

ASME. (2019). Boiler and Pressure Vessel Code, Section VIII.

ISO. (2015). Quality Management Systems – Requirements (ISO 9001:2015).