Lord Fin Tube--Studded tubes manufacturer

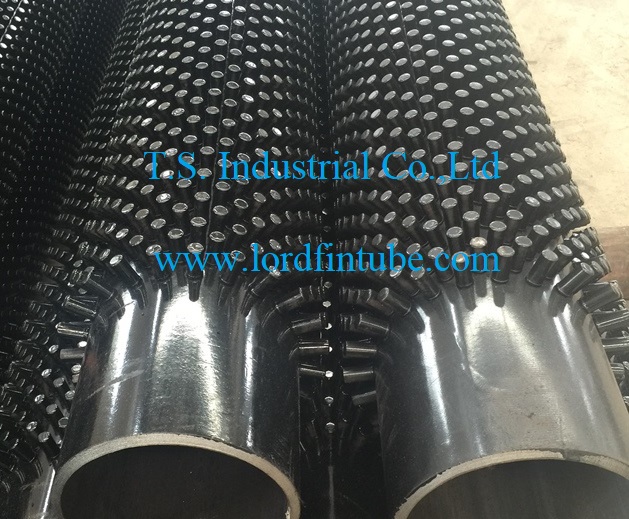

Studded tubes (or stud-welded tubes) are specialized heat transfer surfaces designed to maximize thermal efficiency in industrial equipment like boilers, heat exchangers, and furnaces.

1. Studded Tubes Definition & Core Applications

Studded tubes (or Pin Pipes) are steel pipes with externally welded studs or protrusions, typically made of carbon steel, stainless steel (AISI 304/410), or specialty alloys (e.g., Inconel, Monel). These studs enhance surface area and functional performance for industrial applications.

Primary Uses

Heat Transfer Enhancement: Optimizes thermal efficiency in boilers, heat exchangers, and furnaces by disrupting laminar flow and increasing turbulence.

Abrasion/Wear Resistance: Protects pipelines handling abrasive materials (e.g., fluidized beds, cement kilns).

High-Temp/Pressure Environments: Ideal for petrochemical, power generation, and shipbuilding industries.

2. Studded Tubes Features & Advantages

Structural Design

Stud Arrangement: Staggered rings or helical patterns tailored to maximize heat transfer or wear resistance.

Dual-Surface Design: Smooth inner bore (minimizes pressure drop) + studded exterior (enhances performance).

Performance Benefits

|

Feature |

Advantage |

|

Heat Transfer |

30–50% higher efficiency vs. bare tubes (studs increase surface area + turbulence). |

|

Abrasion Resistance |

Extends service life in particle-laden flows (e.g., coal-fired boilers). |

|

Anti-Fouling |

Studs reduce sediment buildup, lowering maintenance costs. |

|

Mechanical Strength |

Withstands pressures up to 150 bar and temperatures exceeding 600°C. |

3. Studded Tubes Materials & Manufacturing Process

Material Options

Carbon Steel: Cost-effective for general-purpose use.

Stainless Steel (AISI 304/316): Corrosion-resistant for chemical/petrochemical apps.

Nickel Alloys (Inconel): Extreme heat/corrosion resistance (e.g., sulfuric acid recovery).

Production Techniques

Stud Welding: Automated drawn-arc or resistance welding ensures strong, consistent bonds. Base Tube Fabrication: Seamless or welded tubes (OD: 60.3–219 mm; lengths up to 20 meters).

Quality Control: NDT Testing: X-ray/ultrasonic inspection for weld integrity. Pressure Testing: Validates performance under operational conditions.

4. Studded Pipes Technical Specifications

|

Parameter |

Range/Capability |

Standards Compliance |

|

Tube OD |

60.3–219 mm |

ASTM A213, ASME SA192 |

|

Stud Height |

6–25 mm (customizable) |

ISO 9001 |

|

Pressure Rating |

Up to 150 bar |

PED 2014/68/EU |

|

Temperature |

-50°C to +800°C (material-dependent) |

EN 10204 3.1 Certification |

5. Studded Tubes Industry Applications

Sector-Specific Uses

Power Generation: Boiler superheaters, economizers (coal/gas-fired plants). Waste heat recovery systems (improves energy efficiency by 15–20%).

Oil & Gas: Refinery reheaters, sulfur condensers.

Chemical Processing: Reactors, acid-cooling pipelines (resists H₂SO₄/HCl atmospheres).

Metallurgy: High-temperature flue gas ducts (reduces erosion in sintering plants).

Compatible Equipment Shell-and-tube heat exchangers Fluidized bed reactors Thermal oxidizers