Products Description

What are studded Tubes & Studded Pipes?:

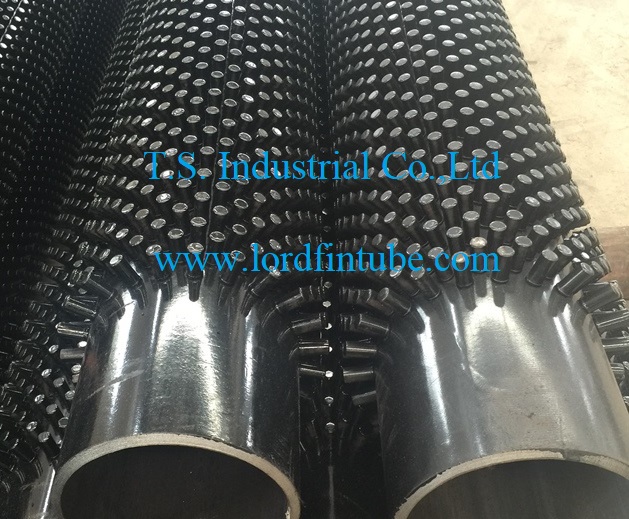

Studded tubes are a variant of metal tubes featuring studs that are welded onto their surface. These studs are strategically positioned along the length of the tube. Commonly found in applications such as boilers and refineries, studded tubes enhance the surface area, which facilitates improved heat transfer, making them ideal for reheating purposes. The studs are welded on the tubes using electrical resistance welding, producing high quality welds. Studded tubes have better preference than finned tubes in heat transfer systems in petrochemical plants, where the surface is exposed to very corrosive environment such as dirty gases or liquids. These tubes should be resistant to aggressive materials and must be cleaned frequently.

Studded Tubes Materials: Base Tube/Pipe & Studs:

Carbon Steel Pipe

- ASTM A192: Standard specification for seamless carbon steel boiler tubes for high-pressure service.

- ASTM A213: Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

- ASTM A106: Although primarily for carbon steel pipes, it’s often used in applications requiring high-temperature service.

Alloy Steel Pipe

- ASTM A335: Specification for seamless ferritic alloy-steel pipe for high-temperature service, commonly used in boiler applications.

- ASTM A199: Standard specification for seamless ferritic and austenitic alloy-steel boiler tubes, designed for high-temperature applications.

Stainless Steel Pipe

- ASTM A312: Standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes, suitable for high-pressure and temperature applications in boilers.

Carbon Steel & Alloy Studs

- Grade 2: Low-strength steel, suitable for general applications.

- Grade 5: Medium-strength steel, often used in structural applications.

- Grade 8: High-strength steel, ideal for heavy-duty applications.

Stainless Steel Studs

- 304: General-purpose stainless steel with good corrosion resistance.

- 316: Offers enhanced corrosion resistance for use in harsh environments.

- 409: General-purpose stainless steel with good corrosion resistance.

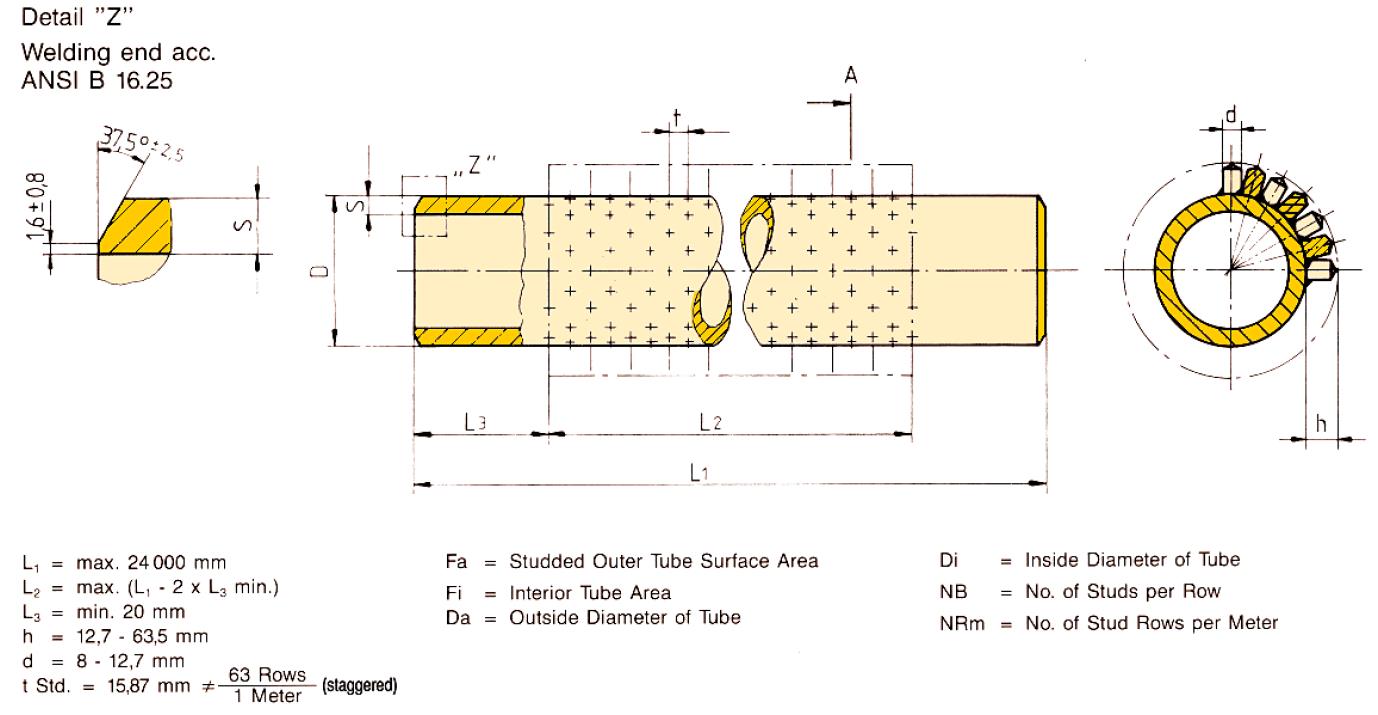

Studded Tubes & Studded Pipes Sizes:

The Standard Tube Dimensions given in the above table are taken from typical orders. We produce studded tubes also with other base tube dimensions in the range 60,3 up to 219,1 mm Outside Diameter.

Up to 24 meters. If necessary with circumferential weld, 100% x-rayed. If required pressure tested.

Studded Tubes Studs

Standard Stud row spacing 5/8" (15,88 mm) = 63 Stud rows per meter, other spacings on request

Studs Shape of Studded Tubes & Studded Pipes

Cylindrical studs , elliptical studs or lens type studs

Studded Tubes & Studded Pipes Fields of application:

1. Power Generation

- Boilers: Studded tubes are used in high-pressure boilers, particularly in superheaters and economizers, to enhance heat transfer efficiency and ensure effective generation of hot water and steam.

- Heat Exchangers: In power plants, studded tubes improve heat exchange efficiency, especially in cooling and heating cycles.

2. Petrochemical Industry

- Cracking Furnaces: Studded tubes are employed in reactors during high-temperature cracking processes to ensure optimal heat exchange and reaction efficiency.

- Heat Exchangers: Used in petroleum refining processes for heating and cooling hot oil.

3. Chemical Processing

- Reactors: In chemical reactions, studded tubes enhance heating and cooling efficiency, especially under high temperature and pressure conditions.

- Separators: Studded tubes help improve energy transfer during separation processes.

4. Marine Applications

- Marine Boilers: Widely used in steam generators on ships for their corrosion resistance and high efficiency.

- Heat Exchangers: Utilized in cooling and heating systems on vessels.

5. Waste Heat Recovery

- Heat Recovery Systems: Studded tubes capture and utilize waste heat from industrial processes, improving overall energy efficiency, particularly in high-temperature exhaust recovery.

6. Oil and Gas

- Drilling and Production Equipment: Used in oil and gas extraction to enhance heat transfer efficiency, especially in environments with significant temperature fluctuations.

Studded Tubes & Studded Pipes Manufacturing process:

Studs are fully automatically welded onto the tube by resistance welding.

The electrical current is directed through both the tube and the base of the studs. These studs are uniquely shaped to enhance the welding process. During the finning and welding procedure, the stud is mechanically pressed against the tube at the weld point, resulting in a strong mechanical bond. This type of fin tube is particularly well-suited for high-pressure and high-temperature applications. The strength of the mechanical bond makes it ideal for environments subject to extreme mechanical loads and stresses, such as during operational processes or cleaning.

Studded Tubes & Studded Pipes Advantages:

Due to their high rigidity, studded tubes can be used even under extreme temperature and pressure conditions.

1. Enhanced Heat Transfer

The studs increase the surface area of the tube or pipe, promoting more effective heat exchange. This makes them particularly efficient in applications requiring quick heating or cooling.

2. Improved Mechanical Strength

The mechanical bond created during the welding process enhances the overall structural integrity of the tube or pipe, allowing them to withstand high pressure and mechanical stress.

3. Durability in Harsh Environments

Studded tubes and pipes are typically made from robust materials (like carbon steel, alloy steel, or stainless steel) that resist corrosion and degradation, making them suitable for use in harsh conditions.

In order to forward you a promt offer we would be pleased to receive you detailed enquiry containing:

• Base tube material and quantity

• Base tube size

• Stud material

• Stud type

• Stud diameter or height

• Stud thickness

• Stud per inch, meter or fin pitch

• Lenght of plain, unfinned ends

(nessesary to roll or weld the tubes into tubeplate or assembly)

Studded Tubes| Studded Pipes