Advantages of Finned tube cooler

A finned tube cooler is an advanced heat exchange device designed to efficiently dissipate thermal energy by transferring heat to the surrounding environment through enhanced surface area. In chemical processing, power generation, and industrial manufacturing applications, finned tube coolers play a critical role in thermal management systems, offering superior performance compared to conventional cooling solutions.Finned tube coolers can achieve heat transfer coefficients 3-5 times higher than bare tube exchangers, making them particularly valuable in applications where space constraints or efficiency requirements demand optimal thermal performance.

Definition and Working Principle of Finned Tube Coolers

A finned tube cooler operates on the fundamental principles of conduction and convection heat transfer, but with enhanced efficiency due to the extended surface area provided by the fins. Thermal energy from the process fluid inside the tubes is conducted through the tube wall to the fins, where it is dissipated to the ambient air through forced or natural convection.

Thermal Performance Metrics

The enhanced surface area of Finned tube cooler designs significantly improves heat transfer efficiency, allowing for more compact heat exchanger designs while maintaining or even improving thermal performance compared to conventional bare-tube systems.

Finned Tube Coolers Structural Design and Configuration

Finned tube coolers feature an optimized design consisting of several key components that work together to maximize heat transfer efficiency:

Enhanced Tubes

The primary heat transfer surface, typically constructed from carbon steel, stainless steel, or copper alloys depending on application requirements and fluid compatibility.

Extended Fins

Thin metallic projections that dramatically increase the effective heat transfer surface area, available in various configurations including helical, longitudinal, and plate fins.

Air Movement System

Axial or centrifugal fans that generate controlled airflow across the finned surfaces, optimizing the convective heat transfer coefficient.

Support Structure

Robust framework that maintains proper tube alignment and fin spacing while withstanding operational thermal stresses and vibrations.

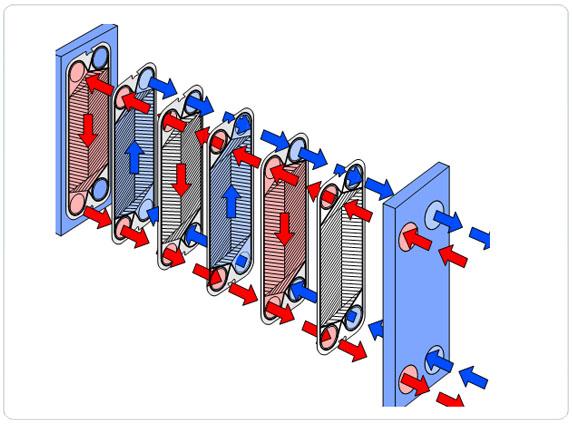

Finned Tube Coolers Operational Methodology

The working process of a finned tube cooler follows a systematic heat transfer sequence:

Step 1: Internal Heat Conduction - Thermal energy from the process fluid is transferred to the inner tube wall through convective heat transfer, then conducted through the tube material.

Step 2: Fin Base Conduction - Heat flows from the tube wall to the base of the fins, where the extended surface area begins to contribute to the overall heat transfer process.

Step 3: External Convection - Forced airflow across the finned surfaces removes thermal energy through convective heat transfer, with the enhanced surface area significantly improving efficiency.

Step 4: Heat Dissipation - The heated air is discharged to the atmosphere, completing the heat rejection process and maintaining the process fluid at the desired temperature.

Advantages of Finned Tube Coolers in Industrial Applications

Finned tube coolers offer significant benefits across various industrial sectors, particularly in chemical processing, power generation, and HVAC applications where efficient heat rejection is critical to operational success.

| Performance Aspect | Finned Tube Cooler | Bare Tube Exchanger | Shell and Tube Heat Exchanger |

|---|---|---|---|

| Heat Transfer Efficiency | High (enhanced surface area) | Moderate | High (liquid-liquid) |

| Space Requirements | Compact | Bulky | Moderate to Large |

| Airside Pressure Drop | Optimized design | Lower | N/A |

| Maintenance Requirements | Low (accessible surfaces) | Low | High (tube bundle removal) |

| Installation Cost | Competitive | Lower initial cost | Higher |

| Operational Flexibility | Excellent | Good | Limited |

Technical Advantages

Enhanced Thermal Performance

The extended surface area of finned tubes significantly improves heat transfer coefficients, with typical surface area increases of 5-20 times compared to bare tubes, resulting in more efficient cooling in compact footprints.

Operational Reliability

With no moving parts in the heat transfer core and robust construction, finned tube coolers deliver exceptional operational reliability with minimal maintenance requirements, reducing downtime and maintenance costs.

Energy Efficiency

Optimized fin designs and airflow management systems reduce fan power requirements while maintaining high heat transfer rates, resulting in lower operational energy consumption and reduced lifecycle costs.

Environmental Compatibility

As closed-loop systems that use ambient air as the cooling medium, finned tube coolers eliminate water consumption and minimize environmental impact while avoiding cross-contamination between process fluids and cooling media.

Design Flexibility

Available in various configurations, materials, and fin types to suit specific application requirements, including high-temperature, corrosive, or fouling service conditions.

Economic Advantages

Lower installation costs compared to water-cooled systems, reduced space requirements, and minimal operational expenses contribute to an attractive return on investment for industrial applications.

Industry Application Data: In chemical processing plants, finned tube coolers typically demonstrate a 25-40% reduction in total cost of ownership compared to conventional shell and tube heat exchangers for gas cooling applications, with payback periods often under 18 months.

The comprehensive advantages of Finned tube cooler technology make it the preferred solution for numerous industrial cooling applications, particularly where space constraints, efficiency requirements, or environmental considerations are paramount. Continued innovation in fin designs, materials, and manufacturing techniques further enhances the performance and applicability of these efficient heat exchange systems across diverse industrial sectors.