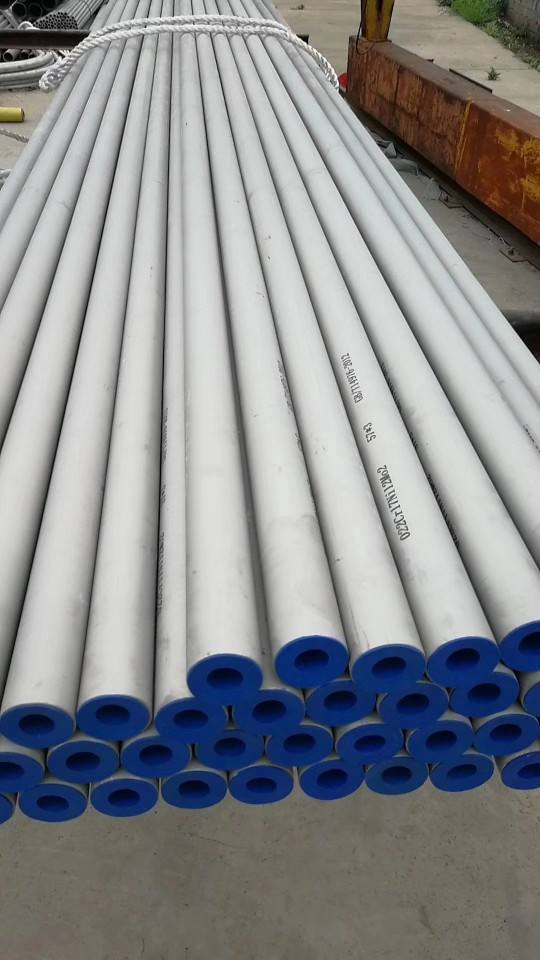

Lord Fin Tube-Urea resistant stainless steel 00cr25ni22mo2n

Tube Sheet Drilling: Precision Techniques and Industrial Applications

Tube sheet drilling is a critical manufacturing process in heat exchanger and boiler fabrication, involving the precise drilling of holes in tube sheets to accommodate tubes that facilitate heat transfer between fluids. This specialized process requires extreme precision to ensure proper fit, alignment, and sealing of tubes within the sheet.

What is Tube Sheet Drilling?

Tube sheet drilling refers to the process of creating precisely spaced and sized holes in tube sheets—the plates that support and separate tubes in heat exchangers, boilers, and other industrial equipment. The accuracy of this drilling process directly impacts the efficiency and longevity of the heat transfer equipment.

Key Aspects of Tube Sheet Drilling

1. Precision Requirements

Tube sheet drilling demands exceptionally tight tolerances, typically within ±0.05mm for hole diameter and ±0.1mm for hole positioning. This precision ensures proper tube fitment, minimizes stress concentrations, and prevents potential leak paths in the final assembly.

2. Materials and Tooling

Tube sheets are commonly manufactured from various materials including carbon steel, stainless steel, brass, and exotic alloys like 00Cr25Ni22Mo2N. Each material requires specific drilling techniques and tooling considerations:

| Material | Recommended Drill Type | Cutting Speed (RPM) | Special Considerations |

|---|---|---|---|

| Carbon Steel | HSS or Carbide | 30-60 | Use cutting fluid for cooling |

| Stainless Steel | Carbide | 10-30 | Slow speed to prevent work hardening |

| Nickel Alloys | Carbide or Cobalt | 5-15 | High pressure coolant required |

| Brass/Copper | HSS | 60-100 | Sharp tools to prevent material pulling |

3. Drilling Techniques

Modern tube sheet drilling employs several advanced techniques:

- CNC Drilling: Computer Numerical Control ensures precise hole patterns and consistent quality

- Gun Drilling: For deep hole applications with minimal deviation

- BTA Drilling: Deep hole drilling system that provides excellent surface finish

- Multi-spindle Drilling: Simultaneous drilling of multiple holes for increased efficiency

4. Quality Control Measures

Rigorous quality checks are essential throughout the tube sheet drilling process:

- Dimensional verification using CMM (Coordinate Measuring Machine)

- Surface finish analysis

- Hole perpendicularity checks

- Burr inspection and removal

- Visual examination for microcracks

Industrial Applications of Tube Sheet Drilling

Heat Exchangers

Shell and tube heat exchangers require precisely drilled tube sheets to maintain thermal efficiency and prevent fluid mixing.

Boilers

Steam generation systems depend on accurately drilled tube sheets to support water tubes and maintain system integrity.

Nuclear Power Plants

Nuclear steam supply systems utilize tube sheets with exceptionally precise drilling tolerances for safety-critical applications.

Petrochemical Industry

Refinery heat exchangers and condensers require corrosion-resistant materials and precision drilling for harsh environments.

Challenges in Tube Sheet Drilling

Tube sheet drilling presents several technical challenges that manufacturers must address:

- Work Hardening: Certain materials like stainless steel tend to harden during drilling, requiring specialized techniques

- Heat Management: Excessive heat can alter material properties and affect dimensional accuracy

- Chip Evacuation: Proper removal of drilling chips is critical for hole quality and tool life

- Tool Wear: Hard materials accelerate drill bit wear, necessitating frequent tool changes and inspections

- Hole Alignment: Maintaining perfect alignment across thick tube sheets requires specialized equipment

Advanced Technologies in Tube Sheet Drilling

Recent advancements in tube sheet drilling technology include:

- Laser-guided Positioning Systems: Enhance accuracy in hole placement

- Adaptive Control Systems: Automatically adjust drilling parameters based on real-time feedback

- Automated Tool Changing: Reduce downtime and maintain consistent quality

- In-process Monitoring: Sensors that detect tool wear and potential defects during operation

- CAD/CAM Integration: Streamline the transition from design to manufacturing

Material Considerations: Urea-Resistant Stainless Steel 00Cr25Ni22Mo2N

In applications involving corrosive environments like urea production, specialized materials such as urea-resistant stainless steel 00Cr25Ni22Mo2N are often employed for tube sheets. This duplex stainless steel offers:

- Excellent resistance to urea corrosion

- High mechanical strength and toughness

- Good resistance to chloride stress corrosion cracking

- Cost-effectiveness compared to highly alloyed alternatives

When drilling tube sheets from 00Cr25Ni22Mo2N or similar duplex stainless steels, special considerations include:

- Using sharp carbide tooling with positive rake angles

- Maintaining consistent feed rates to prevent work hardening

- Employing high-pressure coolant systems for heat dissipation

- Implementing peck drilling cycles for deep holes

Conclusion

Tube sheet drilling is a specialized manufacturing process that requires precision, expertise, and advanced equipment. The accuracy of this process directly impacts the performance, efficiency, and safety of heat exchange equipment across various industries. As technology advances, CNC-controlled systems and sophisticated tooling continue to enhance the precision and efficiency of tube sheet drilling operations.

For critical applications in corrosive environments, material selection becomes equally important, with specialized alloys like 00Cr25Ni22Mo2N offering the necessary corrosion resistance while maintaining mechanical integrity.