Air Cooler Floating Header Support Structure

2024-03-19Leave a message

Introduce Air Cooler Floating Header Support Structure

During the process of oil and natural gas processing, combustible gases need to be cooled and liquefied through cooling equipment to form liquefied gas for storage and transportation. When the cooling equipment operates, the cooling medium compressed into liquid by the compressor releases a large amount of heat. This heat is exchanged with the air through an air cooler, dissipating the heat from the cooling medium into the air.

Traditional air coolers typically consist of finned tubes and headers. The headers are mounted on both sides of the frame, with the ends of the finned tubes welded to the corresponding headers. The cooling medium flows through the finned tubes for heat dissipation. The headers are either welded or bolted to the frame of the air cooler. When welded, the heat from the finned tubes causes thermal expansion, exerting direct pressure on the weld seams between the finned tubes and the headers, leading to potential cracking of the weld seams and even rupture of the finned tubes, resulting in coolant leakage. When bolted, although the headers can move with the thermal expansion and contraction of the finned tubes, the bolts are not under stress during operation. The weight of the headers will then apply stress on the weld seams between the finned tubes and the headers, increasing the risk of weld seam cracking and coolant leakage.

Air Cooler Floating Header Summary

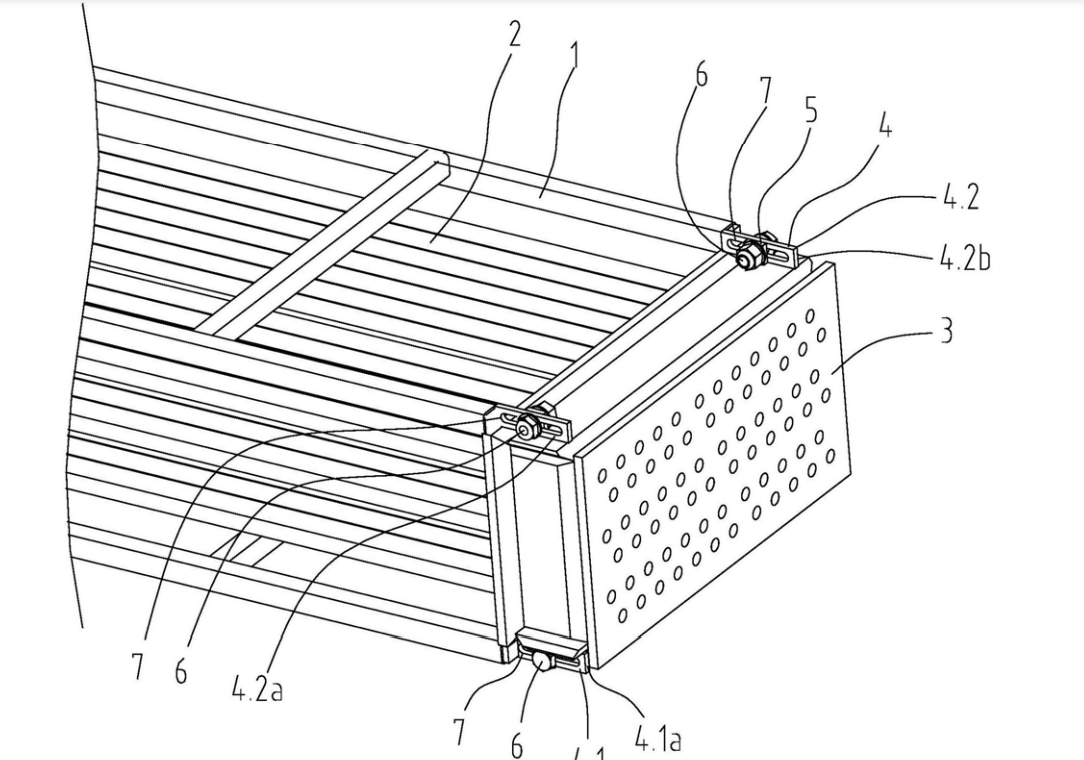

The floating tube header support structure for the air cooler is used to support and fix the floating tube boxes, which are installed on the frame and connected to the finned tubes. It includes a fixed plate mounted on the frame, a connecting plate on the floating tube box in sliding contact with the fixed plate, and bolts connecting the connecting plate to the fixed plate. The bolts installed on the connecting plate pass through installation holes set in the fixed plate, which are slot holes and parallel to the axial direction of the finned tubes. The fixed plate comprises a support plate located below the floating tube box, upon which the floating tube box rests to support it. This support structure bears the weight of the floating tube box through support plates set on the frame, preventing significant stress on the weld seams between the finned tubes and the floating tube box, thus avoiding weld seam cracking and coolant leakage. The floating tube box is able to move relative to the axial direction of the finned tubes to accommodate length changes due to thermal expansion and contraction, preventing the entirety of the thermal expansion force from acting on the weld seams between the finned tubes and the headers, and thereby preventing weld seam cracking and coolant leakage.