ASTM B111 C44300 Naval Brass Tube in Stock

ASTM B111 C44300 Naval Brass Tube In Stock

Available for Immediate Shipment

We maintain substantial stock of ASTM B111 C44300 Naval Brass Tubes to ensure your projects stay on schedule. No more waiting for material delivery during critical equipment maintenance or emergency repairs.

ASTM B111 C44300 Naval Brass Tube Composition

Chemical Composition Analysis

C44300 Naval Brass contains a precise balance of copper, zinc, tin, and the crucial element arsenic that provides its superior corrosion resistance properties.

| Element | Percentage | Function |

|---|---|---|

| Copper (Cu) | 70.0 - 73.0% | Base material providing conductivity and formability |

| Zinc (Zn) | Remainder | Enhances strength and workability |

| Tin (Sn) | 0.9 - 1.2% | Improves corrosion resistance in marine environments |

| Arsenic (As) | 0.02 - 0.06% | Critical for preventing dezincification corrosion |

| Lead (Pb) | ≤ 0.07% | Trace element for machinability |

| Iron (Fe) | ≤ 0.06% | Impurity control |

B111 C44300 Tube Technical Specifications & Mechanical Properties

ASTM B111 C44300 Standard Requirements

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | ≥ 345 MPa (50 ksi) | ASTM E8 |

| Yield Strength (0.5% extension) | ≥ 125 MPa (18 ksi) | ASTM E8 |

| Elongation (% in 50mm) | ≥ 45% | ASTM E8 |

| Rockwell Hardness | B45 - B75 | ASTM E18 |

| Thermal Conductivity | 111 W/m·K | ASTM E1225 |

| Electrical Conductivity | 26% IACS | ASTM B193 |

Performance Comparison: C44300 vs Alternative Materials

| Property | C44300 Naval Brass | 304 Stainless Steel | 90-10 Cupronickel | Aluminum Brass |

|---|---|---|---|---|

| Seawater Corrosion Resistance | Excellent | Good | Excellent | Very Good |

| Thermal Conductivity (W/m·K) | 111 | 16 | 50 | 100 |

| Tensile Strength (MPa) | 345-480 | 515-860 | 310-380 | 370-550 |

| Cost Effectiveness | High | Medium | Low | Medium |

| Resistance to Biofouling | Good | Excellent | Excellent | Good |

| Ease of Fabrication | Excellent | Good | Good | Very Good |

ASTM B111 C44300 Naval Brass Tube Application

The Dezincification Challenge

Ordinary brass alloys are susceptible to dezincification corrosion in seawater or acidic environments, where zinc is selectively leached out, leaving a porous copper structure that compromises mechanical strength and leads to premature failure.

Arsenic as the Solution

The addition of 0.02-0.06% arsenic in C44300 acts as an effective inhibitor that fundamentally prevents dezincification by forming a protective film on the brass surface. Research demonstrates this precise arsenic concentration provides optimal protection without increasing susceptibility to stress corrosion cracking.

Arsenic Range

0.02% - 0.06% by mass fraction provides maximum dezincification resistance while maintaining mechanical integrity.

Corrosion Rate

Field tests show C44300 maintains corrosion rates below 0.025 mm/year in typical seawater applications.

Service Life

Properly maintained C44300 Naval Brass Tube systems demonstrate service lives exceeding 20+ years in marine environments.

ASTM B111 C44300 Naval Brass Tube Industry Applications

Power Generation

Condensers, low-pressure feedwater heaters, and oil cooler tube bundles in thermal and nuclear power plants. Proven performance in temperatures up to 200°C.

Shipbuilding & Marine

Main/auxiliary ship condensers, seawater pipeline systems, evaporators, and marine heat exchangers. Resists saltwater corrosion at flow rates up to 3 m/s.

Chemical Processing

Heat exchangers, cooling coils, and conduits for handling cooling water, weakly acidic media, and alkaline solutions. Compatible with pH ranges of 6.5-8.5.

Desalination Plants

Heat exchange systems in multi-stage flash and multi-effect distillation units. Withstands total dissolved solids up to 45,000 ppm.

ASTM B111 C44300 Naval Brass Tube Customization & Additional Services

While we maintain substantial stock of standard sizes, our manufacturing capabilities extend far beyond inventory items. We provide comprehensive customization services:

Tube Configurations

- Straight lengths (up to 20 meters)

- U-bend tubes (various bend radii)

- Precision-cut to specified lengths

- Internal groove enhancement

Quality Documentation

- Material Test Certificates (MTC)

- Third-party inspection reports

- Chemical analysis certificates

- Non-destructive testing reports

Additional Processing

- Stress relief annealing

- Surface cleaning & passivation

- End finishing & deburring

- Protective packaging

Our C44300 seamless brass tubes can be supplied as straight lengths or manufactured as U-bend tubes according to your specific heat exchanger design requirements.

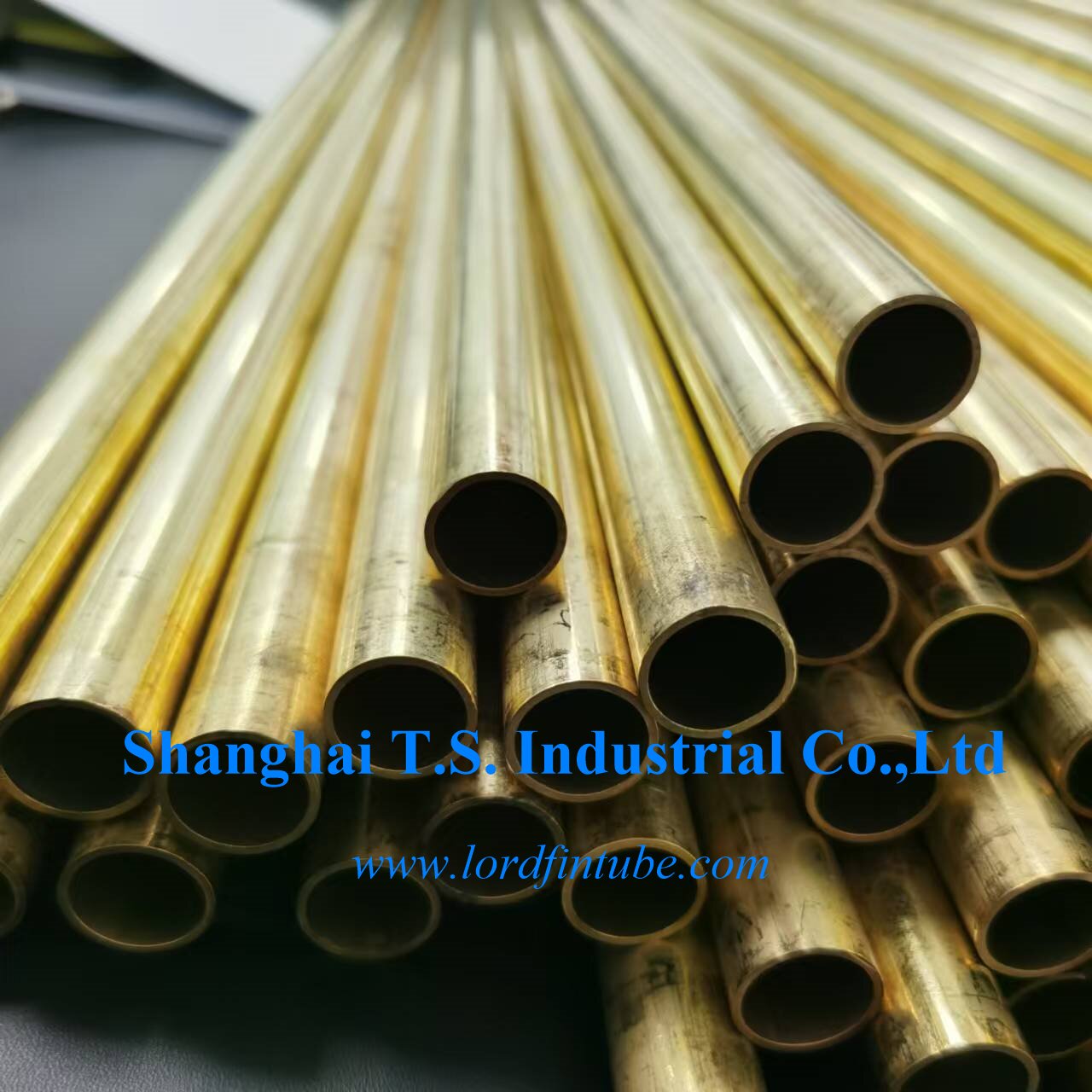

Product Visualization

ASTM B111 C44300 Seamless Brass Tube - Available for Immediate Shipment