Products Description

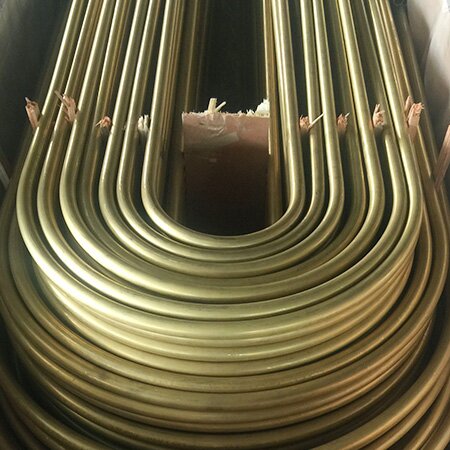

Copper and Copper Alloy U-Bending Tubes

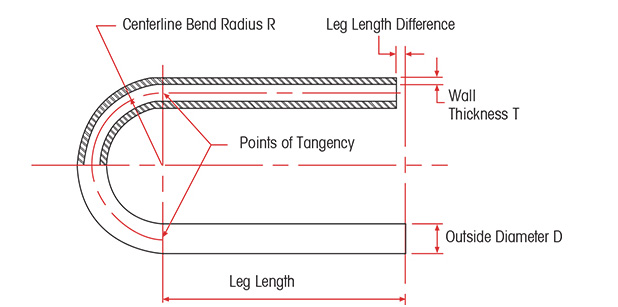

Our copper and copper alloy U-bending tubes are precision-engineered using advanced cold-working techniques to deliver exceptional performance and reliability across various industrial applications. These tubes are specifically tailored to meet diverse client specifications, including custom bending radii, wall thicknesses, and dimensions.

Our U-bend tubes are used across a variety of industries for applications such as boilers, condensers, evaporators, heat exchanger tube bundles, coolers, intercoolers, chillers, and more. They are also widely utilized in industries such as fertilizer plants, sugar mills, steel plants, oil & gas facilities, chemical and petrochemical plants, refineries, power plants, and renewable energy plants.

Copper Alloy U-Bending Tubes Production Process:

Our production process integrates state-of-the-art equipment and rigorous quality checks to ensure durability, reliability, and efficiency:

⇒Straight Tube Preparation: Tubes are precision-cut to the required lengths.

⇒Bending: Advanced bending machines and molds deliver accurate, seamless U-bends with minimal deformation.

⇒Flaw Detection: Tubes undergo 100% inspection pre- and post-bending using non-destructive testing methods.

⇒Stress Relief Annealing: Post-bending, tubes are annealed using electric heating to relieve residual stresses, ensuring mechanical integrity.

⇒Hydrostatic Testing: Each tube is subjected to rigorous water pressure testing to confirm its leak-proof performance.

Copper and Copper Alloy U-Bending Tubes Features:

⇒Seamless Construction – U-bends are seamlessly formed, eliminating the risk of wrinkles, bulges, or any other structural imperfections.

⇒Large Radius Bends – Ideal for pneumatic conveyors and other applications that require large-radius bends.

⇒Low Ovality – Extremely low ovality ensures the tube remains perfectly round for improved flow dynamics and efficiency.

⇒Aesthetic Surface – Tubes have a visually pleasing finish, with deburred saw edges, ensuring a smooth, scratch-free surface.

⇒Easy Installation – The tubes come with leg extensions on both sides for ease of installation and are safe for use in food-grade environments.

Copper and Copper Alloy U-Bending Tubes Applications:

⇒Heat Exchangers: Efficient heat transfer for industrial and commercial systems.

⇒Power Plants: Used in condensers, boilers, and low-pressure economizers.

⇒Chemical and Petrochemical Plants: Corrosion-resistant and robust for demanding conditions.

⇒Renewable Energy Systems: Supporting sustainable energy solutions in solar and geothermal plants.

⇒Oil & Gas: Ideal for offshore platforms and refineries.

Copper and Copper Alloy U-Bending Tubes Material Standards and Grades:

We offer U-bending tubes made from high-quality materials to suit a wide range of operational demands. These include:

Copper and Copper Alloys: JIS H3300 C1220, ASTM B68 C12200, BS2871 C106, EN 12735-2 CU-DHP, DIN SF-Cu.

Specialized Alloys: Aluminum Brass (ASTM B111 C68700), Admiralty Brass (ASTM B111 C44300), Copper-Nickel (ASTM B111 C70600, C71500, C71640).

Customized Options: Tailored grades for specific requirements in condensers, heat exchangers, and evaporators.

Copper and Copper Alloy Tubes:

⇒JIS H3300 C1220 (Copper Tube)

⇒ASTM B68 C12200, BS2871 C106, EN 12735-2 CU-DHP, DIN SF-Cu

⇒ASTM B135 (Copper Alloys: C33000, C28000, C27000, C27200, C27400, C26000, C26200, C26800, C23000) – Suitable for Condensers, Evaporators, Coolers, Chillers.

⇒ASTM B111 C68700 (Aluminum Brass Tube), BS EN12451(B2871) CuZn20A12As (CZ110) – For Condensers and Evaporators.

⇒ASTM B111 C44300 (Admiralty Brass Tube), BS EN12451(B2871) CuZn28Sn1As (CZ111) – For Condensers, Evaporators, Coolers, and Chillers.

⇒ASTM B111 C70600 (Copper-Nickel Tube), BS EN12451(B2871) CuNi10Fe1Mn (CN102) – For Condensers, Evaporators.

⇒ASTM B111 C71500 (Copper-Nickel Tube), BS EN12451(B2871) CuNi30Fe1Mn (CN107, CN108) – For Condensers, Evaporators, Coolers, Chillers.

⇒ASTM B111 C71640 (Copper-Nickel Tube), BS EN12451(B2871) CuNi30Fe1Mn (CN108) – For Heat Exchanger Tube Bundles.