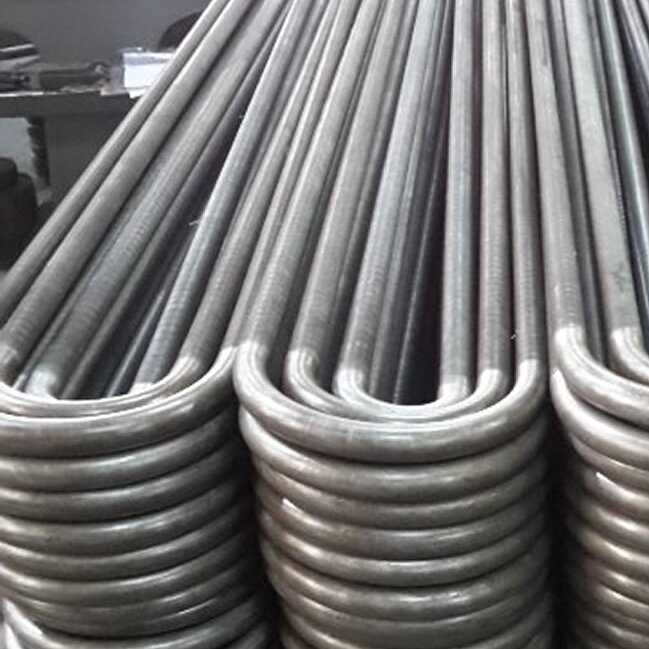

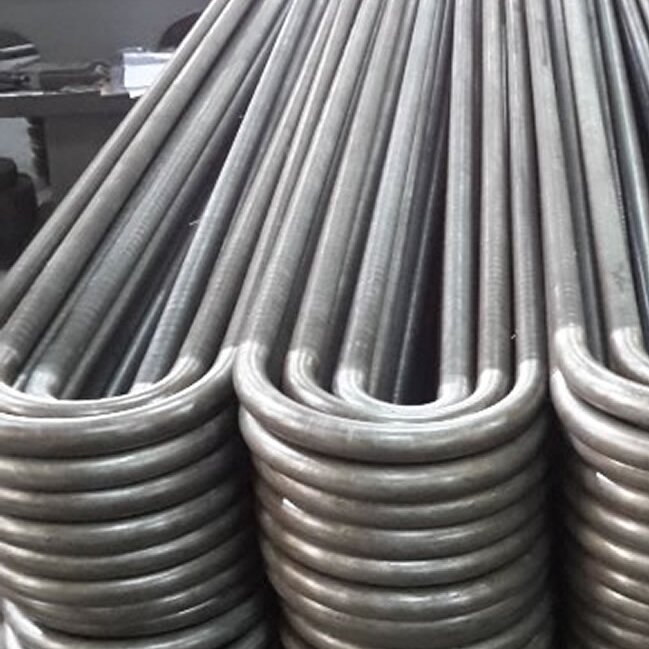

Products Description

The SA334 Gr.6 U-bend low finned tube is an advanced component designed for optimal heat exchange efficiency in low-temperature environments. Constructed from SA334 Gr.6 low-temperature carbon steel, it boasts outstanding toughness, impact resistance, and thermal conductivity. This tube is particularly well-suited for the petroleum, natural gas, chemical, and refrigeration sectors, especially in low-temperature conditions.

1. SA334 Gr.6 U-bend low finned tube Material Properties and Compliance

- SA334 Gr.6 Low-Temperature Carbon Steel: This carbon steel grade, defined by ASTM A334, is specifically engineered for durability and toughness in low-temperature conditions, performing reliably at temperatures down to -45°C. Its carefully controlled carbon and manganese content enhances both ductility at low temperatures and resistance to brittle fractures. Additionally, the material’s natural resistance to oxidation and corrosion makes it ideal for challenging environments.

- Standards and Certifications:

The tube meets ASTM and ASME standards for low-temperature applications and is accompanied by an EN10204-3.2 certification for complete traceability and compliance with quality standards.

2. SA334 Gr.6 U-bend low finned tube Tube Dimensions and Fin Design

- Tube Size:

- Outer Diameter (OD): 19.05 mm - Wall Thickness: 2.108 mm, consistently maintained for optimal heat transfer efficiency and structural integrity.

- Fin Configuration:

- Each tube features precision-rolled low fins with a height of 1.42 mm and a density of 19 fins per inch (fpi). This fin configuration greatly enhances the heat transfer capacity while preserving mechanical strength.

- Base Thickness Under Fins: 1.651 mm, providing robustness in high-stress situations and enhancing wear and damage resistance.

- Non-Finned Sections: The U-bend segment and 203.2 mm (8 inches) at each end are unfinned, allowing for secure sealing and welding, which simplifies installation and improves joint reliability.

3. U-Bend Formation and Stress Relief Process

- Precision U-Bend Fabrication: The U-bends are manufactured in accordance with TEMA (Tubular Exchanger Manufacturers Association) 9th edition guidelines, ensuring the precise bend radius, straightness, and tolerances required for compatibility with other components.

- Electric Resistance Stress Relief: Each U-bend is subjected to electric resistance heating at 610°C for 15 seconds to relieve residual stress at the bend. This process stabilizes the grain structure in the bend area, minimizing the risk of fatigue or cracking—essential for reliable performance under thermal and mechanical stress.

U bend low fin tube

4. U Bend Lowfin Tube Hydrotesting and Quality Assurance

- Hydrostatic Pressure Testing: Each tube undergoes a rigorous 100% hydrostatic test at 70 bar for 10 seconds to confirm pressure resistance and integrity, enabling early detection of micro-cracks and ensuring the tubes capability to handle high-pressure applications without leaking.

- Detailed Quality Checks:

- Dimensional Verification: Inspection of fin and U-bend dimensions to ensure strict adherence to design specifications.

- Heat Treatment Documentation: A report confirming the stress-relief treatment of the bend verifies compliance with the prescribed thermal processes.

- Packaging Certification: Tubes are packaged in compliance with international export standards, ensuring protection during shipping.

5. U Bend Lowfin Tube Packaging and Transport

- Protective Export Packaging: Tubes are securely packed in sturdy, export-ready wooden cases with internal shock-absorbing materials to safeguard against damage during transit.

- Identification and Documentation: Each case is clearly labeled for easy identification and includes complete documentation covering tube specifications, material certificates (EN10204-3.2), and testing reports for full transparency and traceability.

6. U Bend Low fin tube Applications and Performance Benefits

- Enhanced Heat Transfer: The low-fin design significantly amplifies the external surface area of the tube, thus optimizing heat transfer. The U-bend configuration allows for multiple fluid passes, facilitating efficient heat exchange within a compact layout.

- Adaptability to Low-Temperature Environments: The SA334 Gr.6 material maintains high toughness at low temperatures, making it suitable for extreme conditions often encountered in LNG facilities, chemical processes, and refrigeration systems.

- Durability and Reduced Maintenance: The material’s low-temperature ductility, stress-relieved U-bends, and thorough pressure testing contribute to long-lasting durability, minimizing downtime and maintenance costs related to leaks or fatigue failures.

- Simplified Installation: The unfinned ends of the U-bend tube ease welding and sealing, streamlining the installation process and promoting system reliability.

7. U Bend Lowfin tube Typical Use Cases

- Petroleum and Natural Gas: Commonly utilized in LNG plants and natural gas separation systems where efficient heat exchange is critical for optimizing energy in low-temperature processes.

- Chemical Processing: Used in low-temperature coolers, evaporators, and condensers where significant heat exchange is required at sub-zero temperatures.

- Industrial Refrigeration and HVAC: A crucial part of condensers and evaporators in industrial refrigeration units, ensuring energy-efficient temperature management through effective heat transfer.

8. U Bend low finned tube Competitive Advantages

- The SA334 Gr.6 U-bend low finned tube combines superior thermal efficiency, optimum low-temperature performance, dependability, and low maintenance needs, making it an exceptional option for industrial heat exchange applications. It addresses the need for effective and reliable heat transfer within the petrochemical, oil, and gas sectors while offering cost-efficiency due to its enhanced heat transfer capabilities without increasing the exchanger size or requiring frequent upkeep.