Products Description

What is ASTM B395 Standard?

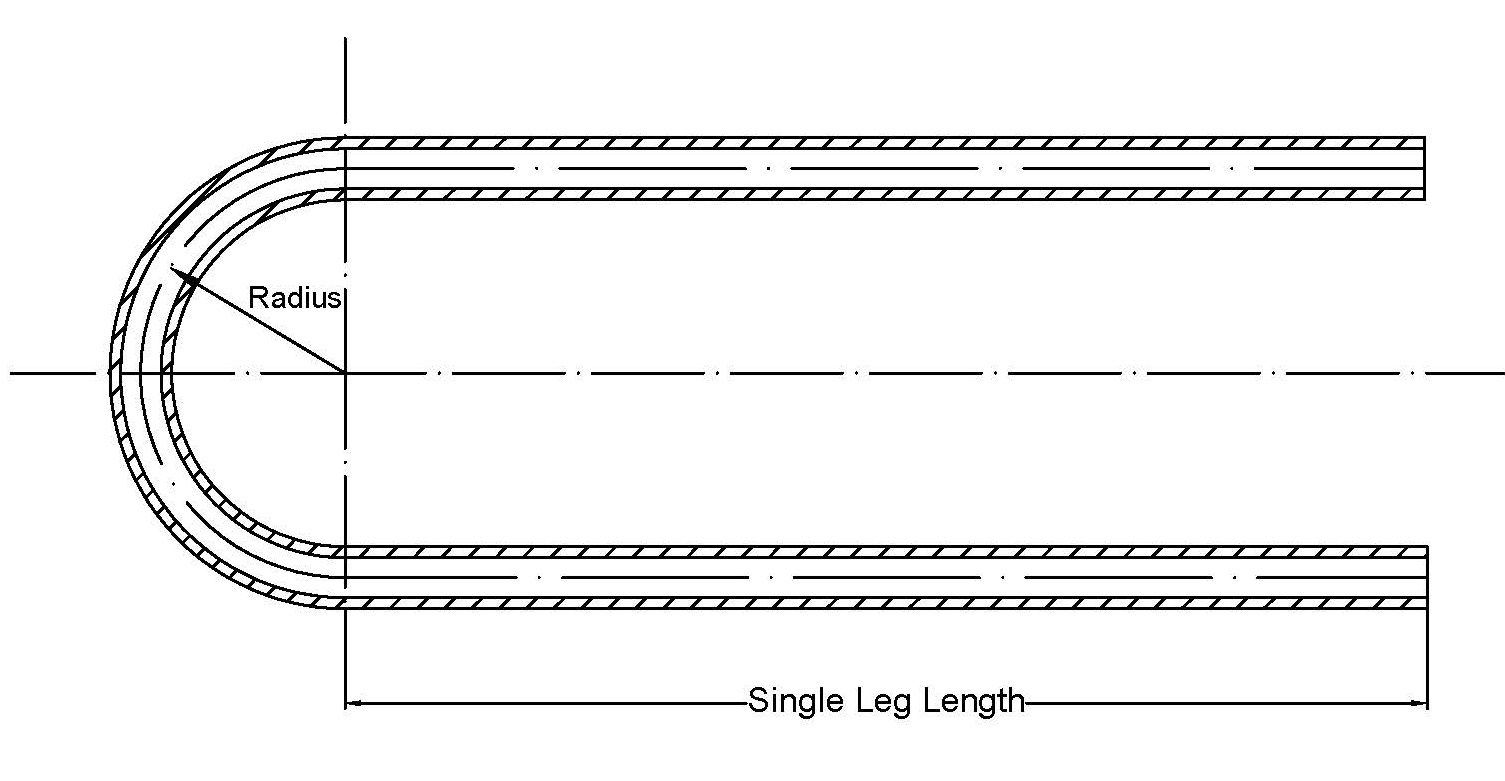

Structural Design of U-Bend tubes

How tube bundle works?

Specifications of B395 U-Bend Tubes

Copper Alloy Common Grades & Chemical Composition

|

Grade |

Cu① |

Sn |

Al |

Ni+Co |

Pb |

Fe |

Zn |

Mn |

As |

Sb |

P |

Cr |

其他元素 |

|

C10200①② |

≥99.95 |

|

|

|

|

|

|

|

|

|

|

|

O:≤10ppm |

|

C10300① |

≥99.95③ |

|

|

|

|

|

|

|

|

|

0.001-0.005 |

|

|

|

C10800① |

≥99.95③ |

|

|

|

|

|

|

|

|

|

0.005-0.012 |

|

|

|

C12000① |

≥99.9③ |

|

|

|

|

|

|

|

|

|

0.004-0.012 |

|

|

|

C12200① |

≥99.9 |

|

|

|

|

|

|

|

|

|

0.015-0.04 |

|

|

|

C14200① |

≥99.4 |

|

|

|

|

|

|

|

0.15-0.5 |

|

0.015-0.04 |

|

|

|

C19200④ |

≥98.5 |

|

|

|

|

0.8-1.2 |

≤0.2 |

|

|

|

0.01-0.04 |

|

|

|

C23000④ |

84-86 |

|

|

|

0.05 |

≤0.05 |

Rest |

|

|

|

|

|

|

|

C44300⑤ |

70-73 |

0.9-1.2 |

|

|

0.07 |

≤0.06 |

Rest |

|

0.02-0.06 |

|

|

|

|

|

C44400⑤ |

70-73 |

0.9-1.2 |

|

|

0.07 |

≤0.06 |

Rest |

|

|

0.02-0.1 |

|

|

|

|

C44500⑤ |

70-73 |

0.9-1.2 |

|

|

0.07 |

≤0.06 |

Rest |

|

|

|

0.02-0.1 |

|

|

|

C60800①⑥ |

Rest |

|

5-6.5 |

|

0.1 |

≤0.1 |

|

|

0.02-0.35 |

|

|

|

|

|

C68700①⑥ |

76-79 |

|

1.8-2.5 |

|

0.07 |

≤0.06 |

Rest |

|

0.02-0.06 |

|

|

|

|

|

C70400①⑥ |

Rest |

|

|

4.8-6.2 |

0.05 |

1.3-1.7 |

≤1 |

0.3-0.8 |

|

|

|

|

|

|

C70600①⑥ |

Rest |

|

|

9-11 |

0.05⑦ |

1-1.8 |

≤1⑦ |

≤1⑦ |

|

|

|

|

|

|

C70620①⑥ |

≥86.5 |

|

|

9-11 |

0.02 |

1-1.8 |

≤0.5 |

≤1 |

|

|

≤0.02 |

|

C:≤0.05 S:≤0.02 |

|

C71000①⑥ |

Rest |

|

|

19-23 |

0.05⑦ |

≤1 |

≤1 |

≤1⑦ |

|

|

⑦ |

|

⑦ |

|

C71500①⑥ |

Rest |

|

|

29-33 |

0.05⑦ |

0.4-1 |

≤1⑦ |

≤1 |

|

|

|

|

③ |

|

C71520①⑥ |

≥65 |

|

|

29-33 |

0.02 |

0.4-1 |

≤0.5 |

≤1 |

|

|

≤0.02 |

|

C:≤0.05 S:≤0.02 |

|

C72200①④ |

Rest |

|

|

15-18 |

0.05⑦ |

0.5-1 |

≤1⑦ |

≤1 |

|

|

⑦ |

0.3-0.7 |

⑦⑧ |

Tension Properties of ASTM B395 Common Grades

|

Grade |

Temper |

Tensile Strength, ksi [MPa] |

Yield Strength, ksi [MPa] |

Elongation in 2 in. |

|

C10200 C10300 C10800 C12000 C12200 C14200 |

H55 |

≥36 [250] |

≥30 [205] |

- |

|

C19200 |

H55 |

≥40 [275] |

≥35 [240] |

- |

|

O61 |

≥38 [26] |

≥12 [85] |

- |

|

|

C23000 |

O61 |

≥40 [275] |

≥12 [85] |

- |

|

C44300 C44400 C44500 |

O61 |

≥45 [310] |

≥15 [105] |

- |

|

C60800 |

O61 |

≥50 [345] |

≥19 [130] |

- |

|

C68700 |

O61 |

≥50 [345] |

≥18 [125] |

- |

|

C70400 |

O61 |

≥38 [260] |

≥12 [85] |

- |

|

H55 |

≥40 [275] |

≥30 [205] |

- |

|

|

C70600 C70620 |

O61 |

≥40 [275] |

≥15 [105] |

- |

|

H55 |

≥45 [310] |

≥35 [2400] |

- |

|

|

C71000 |

O61 |

≥45 [310] |

≥16 [110] |

- |

|

C71500 C71520 |

O61 |

≥52 [360] |

≥18 [125] |

- |

|

WT≤0.048in. (1.22mm) |

HR50 |

≥72 [495] |

≥50 [345] |

≥12% |

|

WT>0.048in. (1.22mm) |

HR50 |

≥72 [495] |

≥50 [345] |

≥15% |

|

C72200 |

O61 |

≥45 [310] |

≥16 [110] |

- |

|

H55 |

≥50 [345] |

≥45 [310] |

- |

Dimensions & Tolerance of ASTM B395 Seamless U-Bend Tubes

|

Outside Diameter |

Wall Thickness |

||||||||

|

in. |

mm |

in. |

mm |

in. |

mm |

in. |

mm |

||

|

in. |

mm |

0.032 |

0.813 |

0.035 |

0.889 |

0.042 |

1.07 |

≥0.049 |

≥1.24 |

|

≤0.5 |

≤12 |

±0.0025 |

±0.064 |

±0.0025 |

±0.064 |

±0.0025 |

±0.064 |

±0.0025 |

±0.064 |

|

0.5<D≤0.74 |

12<D≤18 |

±0.004 |

±0.1 |

±0.004 |

±0.1 |

±0.0035 |

±0.089 |

±0.003 |

±0.076 |

|

0.74<D≤1 |

18<D≤25 |

±0.006 |

±0.15 |

±0.005 |

±0.13 |

±0.0045 |

±0.11 |

±0.004 |

±0.1 |

|

1<D≤1.25 |

25<D≤32 |

±0.009 |

±0.23 |

±0.008 |

±0.2 |

±0.006 |

±0.15 |

±0.0045 |

±0.11 |

|

1.25<D≤1.375 |

32<D≤35 |

- |

- |

- |

- |

±0.008 |

±0.2 |

±0.005 |

±0.13 |

|

1.375<D≤2 |

35<D≤50 |

- |

- |

- |

- |

- |

- |

±0.006 |

±0.15 |

|

Wall Thickness |

Outside Diameter |

||||||

|

in. |

mm |

in. |

mm |

in. |

mm |

||

|

in. |

mm |

1/8<D≤5/8 |

3<D≤16 |

5/8<D≤1 |

16<D≤25 |

1<D≤2 |

25<D≤50 |

|

0.032≤T<0.035 |

0.816≤T<0.889 |

±0.003 |

±0.076 |

±0.003 |

±0.076 |

±0.004 |

±0.1 |

|

0.035≤T<0.058 |

0.889≤T<1.47 |

±0.004 |

±0.1 |

±0.0045 |

±0.11 |

±0.0045 |

±0.11 |

|

0.058≤T<0.083 |

1.47≤T<2.11 |

±0.0045 |

±0.11 |

±0.005 |

±0.16 |

±0.005 |

±0.13 |

|

0.083≤T<0.12 |

2.11≤T<3.05 |

±0.005 |

±0.13 |

±0.0065 |

±0.17 |

±0.0065 |

±0.17 |

|

0.12≤T<0.134 |

3.05≤T<3.4 |

±0.007 |

±0.18 |

±0.007 |

±0.18 |

±0.0075 |

±0.19 |

|

Length |

Tolerance |

||

|

ft |

mm |

in. |

mm |

|

L≤20 |

L≤6000 |

+1/8 |

+3.2 |

|

20<L≤30 |

6000<L≤9000 |

+5/22 |

+4 |

|

30<L≤60 |

9000<L≤18000 |

+1/4 |

+6.4 |

|

L>60 |

L>18000 |

+3/8 |

+9.5 |

Properties of ASTM B395 U-Bend Copper and Copper Alloy Tubes

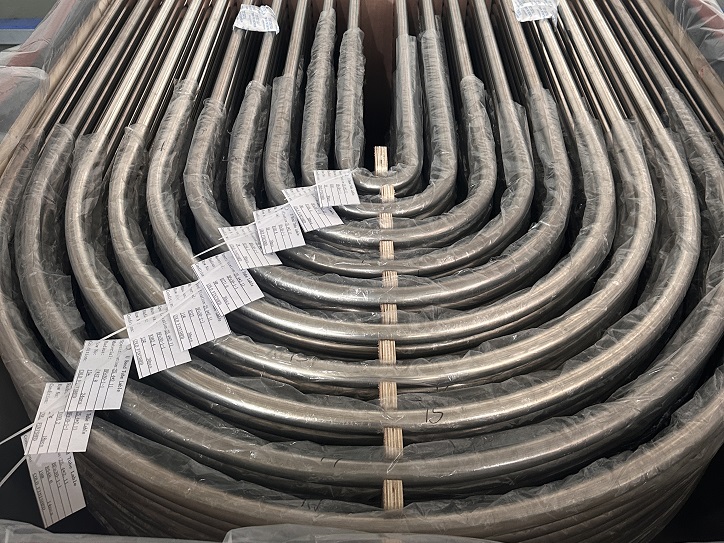

ASTM B395 Copper and Copper Alloy U-Bend Tubes

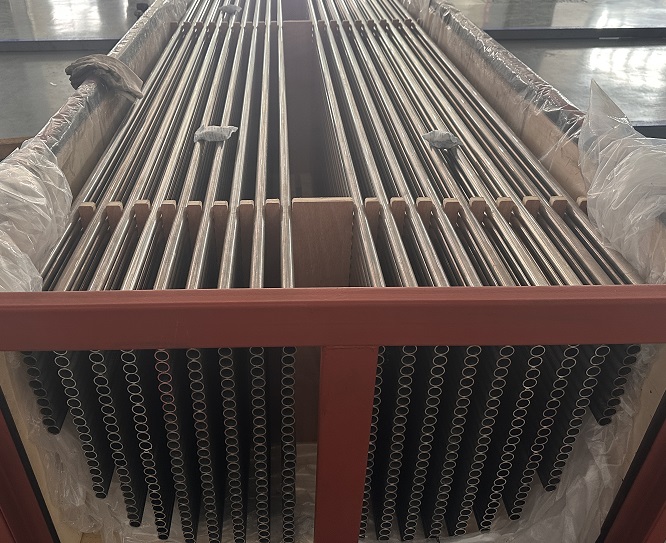

Production Process of ASTM B395 U-Bend Tubes