The role and principle of boiler air preheater

2024-11-10Leave a message

The role and principle of boiler air preheater

The role and principle of boiler air preheater! The heat transfer method of air preheater can be divided into two categories: heat conduction type and regenerative type. The most commonly used in heat conduction air preheater is tubular air preheater. With the improvement of boiler parameters and the increase of capacity, the heating surface of tubular air preheater also increases, which brings difficulties to the layout of the tail heating surface. Therefore, most of the large-capacity units use compact and lightweight rotary air preheaters.

The role of boiler air preheater

The air preheater is also referred to as a heat pipe air preheater. It is a preheating device that improves the heat exchange performance of steam boilers and reduces heat loss. The role of the air preheater is to transfer the heat carried by the flue gas discharged from the tail flue of the boiler to the air before entering the boiler through the heat sink, and preheat the air to a certain temperature. The heat pipe air preheater uses the heat energy carried by the flue gas at the boiler outlet to preheat the boiler combustion air or other drying purposes through the superconducting heat transfer of the heat pipe. Lets talk about the difference between tubular and rotary types.

Tubular boiler air preheater

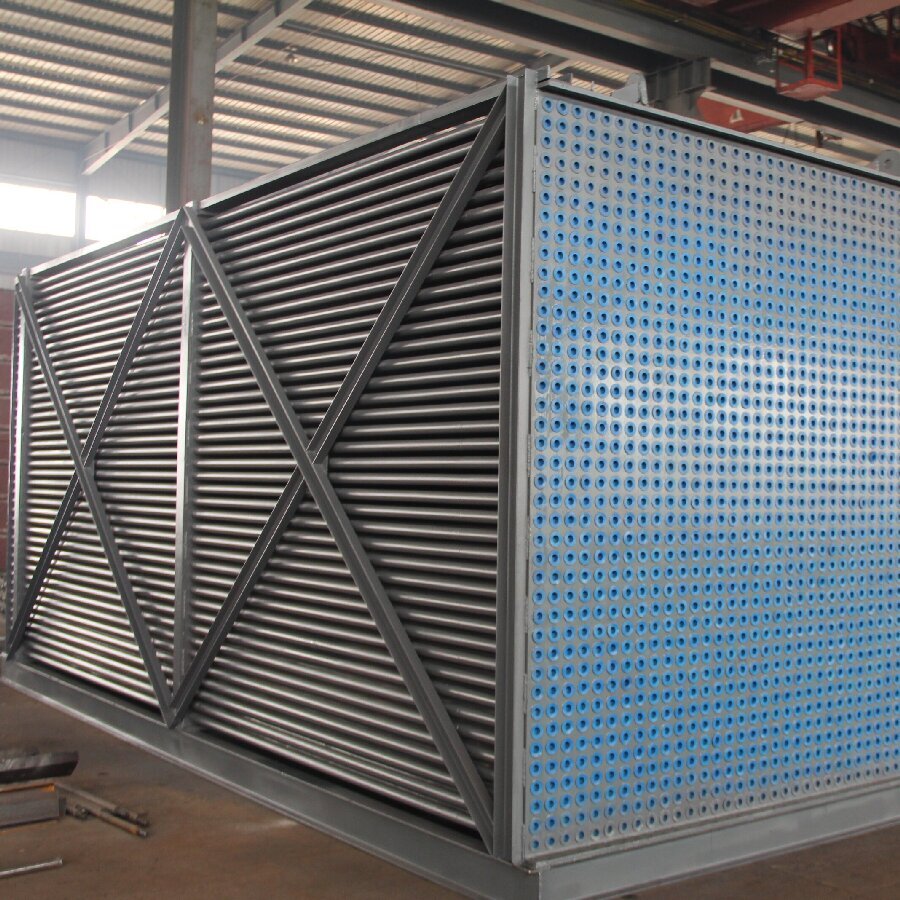

The main heat transfer component of the tubular air preheater is a thin-walled steel tube. Tubular air preheaters are mostly cubic, with steel tubes arranged vertically and staggered with each other, and the two ends welded to the upper and lower tube sheets. The tubular air preheater is equipped with an intermediate tube sheet in the tube box. The flue gas passes through the preheater up and down along the steel tube, and the air passes through the preheater horizontally to complete the heat conduction.

The advantages of tubular air preheaters are good sealing, high heat transfer efficiency, and easy manufacturing and processing. Therefore, they are mostly used in power station boilers and industrial boilers. The disadvantages of tubular air preheaters are large size, easy ash blockage in the steel tube, difficult to clean, and easy wear at the flue gas inlet.

Rotary boiler air preheater

The rotary air preheater is the most common form of regenerative air preheater. It uses flue gas and air to alternately pass through the metal heating surface to heat the air. According to the movement mode, the rotary air preheater can be divided into two types: heating surface rotation and wind hood rotation. The two air preheaters of this furnace are three-compartment heating surface rotary air preheaters.

The rotor rotary air preheater consists of a cylindrical rotor, a fixed cylindrical shell and a drive device.

The structural principle of the boiler air preheater

The heat pipe air preheater adopts a reset placement form, and the flue gas and air flow in reverse horizontal direction to form gas-to-gas heat exchange, which maximizes the flue gas heat exchange efficiency. The heat pipe air preheater consists of a box, a heat pipe bundle, and a middle partition. The box has two sides: one side flows with flue gas and the other side flows with air. The heat pipe air preheater makes full use of the characteristics of fast heat transfer speed and high heat exchange efficiency of the heat pipe, effectively overcoming the problem of low heat exchange coefficient during heat exchange between gases. The heat transfer area of the outer wall at both ends of the heat pipe can be appropriately expanded by using fins. This treatment not only strengthens the heat transfer outside the tube, but also effectively reduces the volume and weight of the heat exchanger, saves metal consumables, and can obtain a cost-effective heat exchanger. At the same time, by adjusting the heat flux density on the heating side and the heat release side of the heat pipe and changing the heat transfer area on the heating side and the heat release side, the acid dew point corrosion of the fluid on the heat exchanger can be effectively avoided, thereby increasing the service life of the equipment.