Carbon Steel Finned Seamless Low Fins Tubes

Carbon Steel Finned Seamless Low Fins Tubes are high-efficiency heat transfer components specifically engineered for enhanced thermal performance. The core consists of high-quality seamless carbon steel base tubes, on which densely arranged low-profile fins (typically 0.5–3 mm in height) are integrally formed on the outer surface through cold-rolling or extrusion processes. This structure expands the heat exchange surface area to 2.5–5 times that of bare tubes without significantly increasing the tube diameter, substantially boosting heat transfer efficiency. Meanwhile, the seamless base tube ensures exceptional pressure-bearing capacity, corrosion resistance, and structural integrity, making it suitable for high-temperature and high-pressure applications. The use of carbon steel offers a balance of strength and cost-effectiveness, while the low-fin design optimizes fluid dynamics and reduces fouling risks. These tubes are primarily used in industrial heat exchange applications such as power plant boilers, petrochemical units, air coolers, and waste heat recovery systems. Carbon Steel Finned Seamless Low Fins Tubes Technical Specification for ASME / PED Heat Exchangers

1.Carbon Steel Finned Seamless Low Fins Tubes Technical Specification Scope

This Technical Specification identifies requirements for Carbon Steel Finned Seamless Low Fins Tubes that are intended for use in ASME Heat Exchangers Section II Part A ASTM A-498.

2.Carbon Steel Finned Seamless Low Fins Tubes Applicable Standards

ASME Boiler and Pressure Vessel Code Applicable Edition is 2023; other referred herein Codes, Standards or Directives shall be of their latest Edition / Addenda: 2.1 2.2 2.3 ASME Boiler and Pressure Vessel Code, Section II Part A ASTM A-498 PED 2014/68/EU

3.Carbon Steel Finned Seamless Low Fins Tubes Material Specification and Grade/Type

ASTM A179 / ASME SA179 – Standard for cold-drawn seamless low-carbon steel tubes for heat exchangers.

Grade: Low-carbon steel (typically C ≤ 0.06%)

Common Use: Ideal for low-finned tubes due to good thermal conductivity and formability.

ASTM A192 / ASME SA192 – Standard for high-pressure carbon steel boiler tubes.

Grade: Similar to A179 but with slightly higher carbon content for strength.

ASTM A210 / ASME SA210 – Standard for medium-carbon steel boiler and superheater tubes.

Grades: A210 Grade A-1 (low carbon)

4.Carbon Steel Finned Seamless Low Fins Tubes Other Acceptable ASTM Editions

The Material Test Reports may stay the compliance to the ASTM applicable specification instead of compliance to ASME specification. In such cases it is the responsibility of the Supplier/Manufacturer to verify that the used ASTM Edition is neither newer than "Latest Adopted" nor older than oldest in range of "Other Acceptable Editions" as listed in the Table II-200-1 of ASME Boiler and Pressure Vessel Code, Section II Part A, Edition 2023.

5.Carbon Steel Finned Seamless Low Fins Tubes Heat Treatment Condition

Tubes shall be annealed after finning according to ASTM A-498. Alternatively, if as fabricated tubes are supplied, the carbon content of the steel shall not exceed 0.11%.

6.Carbon Steel Finned Seamless Low Fins Tubes Straightening

Tubes shall be straightened by stretch method if straightening is necessary or alternatively by slight rolling (initially highly distorted tubes shall be discarded).

7.Carbon Steel Finned Seamless Low Fins Tubes Finish

Tubes shall be clean, free of visible black residues (metallic aspect even if dull required). Tubes shall be free of any surface defects like plug lines, deep scratches, inclusions etc. on both OD and ID and lightly oiled. Tubes shall bear no ID or OD surface injurious defects. Finish will be subjected to prequalification by Lordfintube on sample finned tube.

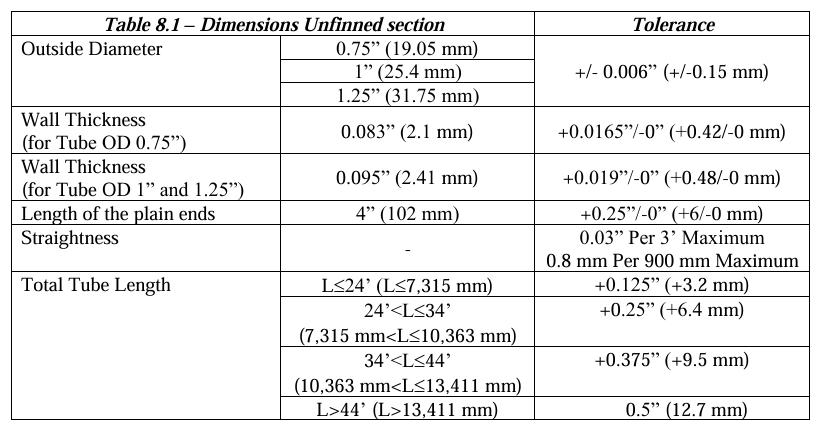

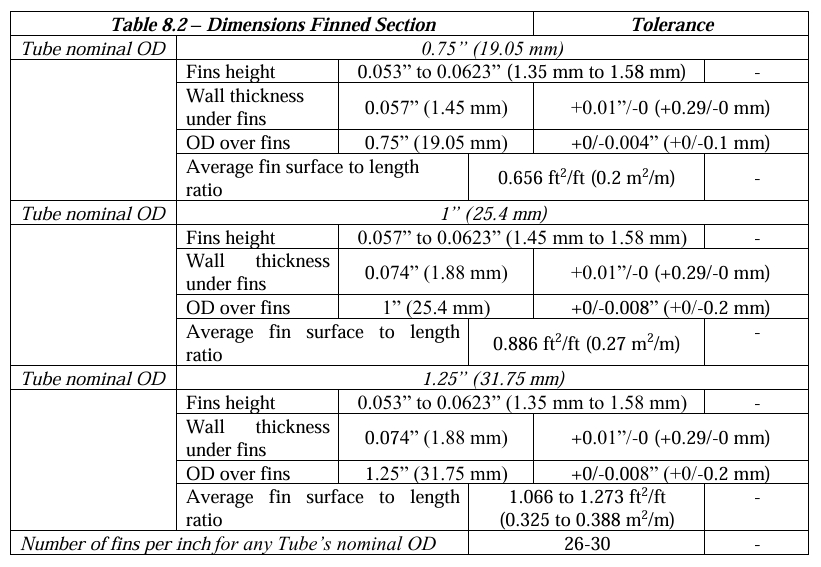

8.Carbon Steel Finned Seamless Low Fins Tubes Dimensions and Tolerances

9.Carbon Steel Finned Seamless Low Fins Tubes Required Tests

9.1 Before finning:

9.1.1 Each tube shall be tested by Eddy Current Test per SA-179 paragraph 11.5 and SA-450 paragraph 25.

9.1.2 Unfinned tubes Material Test Reports (including chemical analysis and heat numbers and E.C. compliance), to be faxed to Lordfintube before starting finning operation.

9.2 After finning:

9.2.1 Each tube shall be subjected to “air under water” test of 250 psi (17.3 bars) for minimum 5 seconds per ASTM A-498 paragraph 8.

9.2.2 Alternative to 9.2.1 above, each tube shall be subjected to the air pressure differential method test of 250 psi (17.3 bars) for minimum 5 seconds per ASTM A-498 paragraph 8. The pressure differential method shall be done as described in ASTM, Material Research Standards Vol.1, No.7, July 1961. Product analysis shall be done per SA-179 paragraph 9 for every heat number. New Manufacturer (Supplier) shall be prequalified also for fin dimensions on sample tubes sent to Lordfintube before order.

10.Carbon Steel Finned Seamless Low Fins Tubes Marking

Markings of each box shall be done by tagging outside and characters of 1-1/2” height shall include:

10.1 Tubes catalog number as it appears in the Lordfintube’s Purchase Order.

10.2 Lordfintube’s Purchase Order number.

10.3 Marking of “LORDFINTUBE”

10.4 Manufacturer name or brand.

10.5 The quantity of tubes in box.

10.6 Specification SA-179, SA-450 and ASTM A-498.

10.7 Heat number, lot number and the marking of “SML”

10.8 The marking of 4 to 5 lifting points when the marking of lifting points shall be done by the sign of an arrow pointing up and the words “LIFT HERE”.

11. Carbon Steel Finned Seamless Low Fins Tubes Quality Control Requirements

Order will not be considered completed and approved for the payment, until Material Test Reports (MTRs) and dimensional reports are received and approved by Lordfintube’s Q.C. The Manufacturer shall send to Lordfintube, within 10 days after receipt of order, a Quality Control Plan to inform Lordfintube about progression of work and allow Lordfintube to schedule "On Site" inspection. Detailed confirmation to each requirement of this specification shall be submitted at order receipt.

12. Carbon Steel Finned Seamless Low Fins Tubes Certificates and Material Test Reports

The raw material should be sourced by final product Manufacturer only from Supplier who holds ISO-9001 Certificate issued by a competent body established within the European Community. For final product, the Certificate of the Material Manufacturer proving its appropriate quality-assurance system certified by a competent body established within the European Community and having undergone a specific assessment for materials, as required by the European PED 2014/68/EU Annex I, section 4.3, shall be forwarded along with quotation. Material Test Reports (MTRs) shall conform to SA-179, SA-450, ASTM A-498 and EN 10204 Type 3.1 as required by this specification and shall include evidence for performance of required heat treatment. One copy shall be presented to Lordfintube Inspector for review and approval. Two original copies shall be attached to the shipping documents.

13. Carbon Steel Finned Seamless Low Fins Tubes Dimensional Reports

The Manufacturer is required to perform one dimensional inspection for each lot of 50 tubes maximum, and issue dimensional check report which covers following items:

13.1 Unfinned section:

13.1.1 Outside diameter, tube wall thickness, length of plain ends.

13.2 Finned section:

13.2.1 Fin height, tube wall thickness under fins, outside diameter over the fins, average number of fins per inch.

13.3 Total tube length. The dimensional check report should be considered a part of the order and should be attached to the shipping documents.

14. Carbon Steel Finned Seamless Low Fins Tubes Inspection

Lordfintube is entitled to perform inspection per ASTM A-498 paragraph 12 and to reject the tubes, before or after shipment, should they be found not conforming to Purchase Order and ASME/PED requirements. Manufacturer shall notify Lordfintube about the production and quality control steps 10 days in advance. Particularly, Manufacturer shall notify Lordfintube about beginning of the Eddy Current Test or Hydrostatic Test or “air under water” Test 10 days in advance. Results of the tests and heat treatment charts shall be retained for eventual review of Lordfintube’s Inspector.

15. Carbon Steel Finned Seamless Low Fins Tubes Packaging Instruction

Packaging shall be designed to endure the stresses associated with lifting and sea transportation.

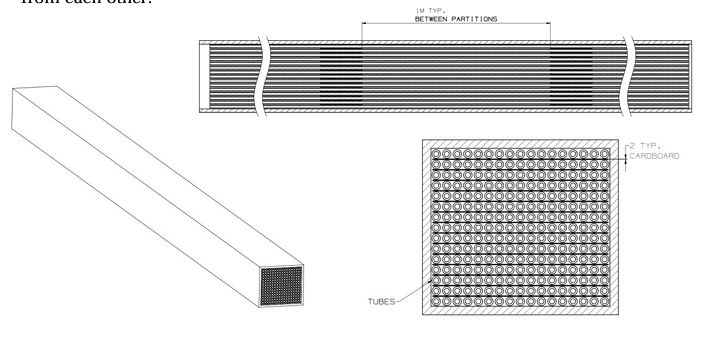

• Tubes shall be packed in a flawless wooden export box, 0.5” (12 mm) plywood or 1” (25 mm) lumber, 2”x4” (50x100 mm) bottoms, side and top cleats spaced every 4’ (1200 mm).

• Allocate sufficient clearance beneath the tubes package to accommodate the forklifts fork. • Tubes shall be double-bagged in polyethylene sleeves, min. 100 µm thickness for each heat-sealed independently; other waterproof double-wrapping may be acceptable, provided that each wrapping is sealed hermetically and independently.

• Cardboard (2 mm) partitions shall be used as buffers to separate rows of tubes from each other.

•Whenever desiccant bags will be used the desiccant agent shall be composed of amorphous silica gel; application of an alternative desiccant agent is allowed only after written approval from LORDFINTUBE; in no event chloride presence of any type is allowed in desiccant bags.

• Extra polyethylene sheet shall be applied between top cover and the box. The overhang of the sheet shall be firmly fastened to the sides of the box. Overlapping of 15” (380 mm) minimum is required.

• The marking on the box shall include the specific production lot number(s), including tag inside of the box.

• Attention shall be paid during loading and unloading operations

Carbon Steel Finned Seamless Low Fins Tubes