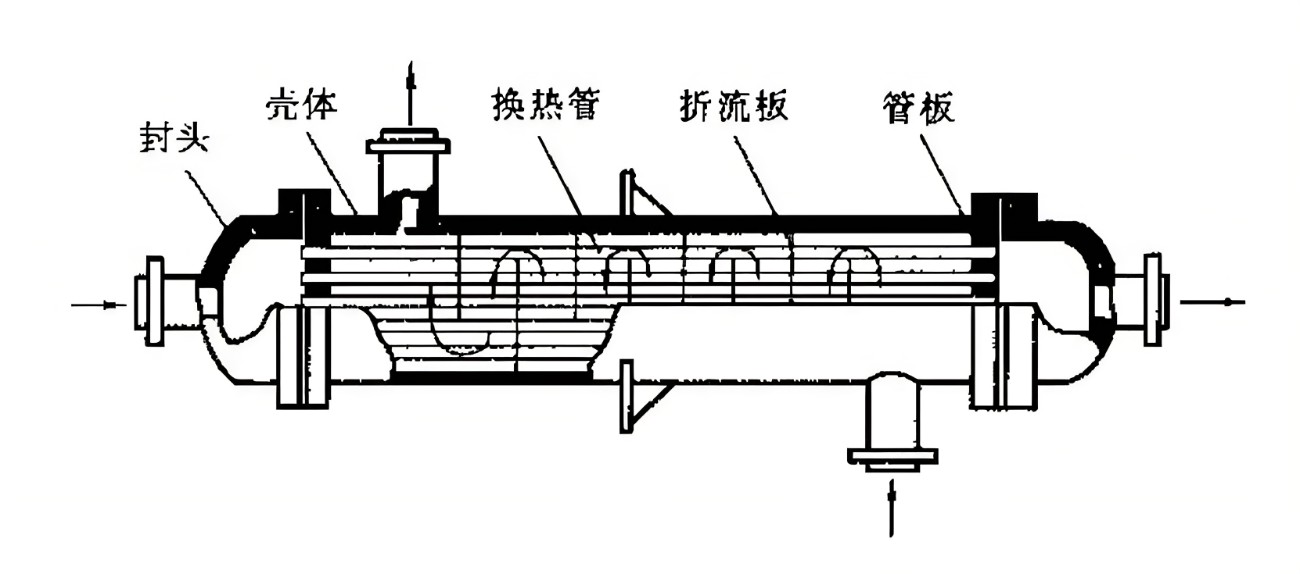

Wear principle and protection measures of shell and tube heat exchanger

Shell-and-tube heat exchangers are widely used in various industries, but wear-related issues remain a significant concern for users. This article provides a comprehensive analysis of wear mechanisms, contributing factors, and effective solutions to enhance understanding and prolong equipment lifespan.

I. Wear Mechanism in Shell-and-Tube Heat Exchangers

During operation, the tubes in a shell-and-tube heat exchanger pass through baffles with small gaps. The continuous flow of shell-side fluid induces tube vibration, leading to wear on both the tubes and baffles. The wear severity depends on vibration intensity—higher vibration accelerates wear, especially when the baffle is thin and hard.

The interaction between tubes and baffles involves complex relative motion, including:

1. Sliding friction from repeated contact and separation

2. Impact forces from collisions

The wear process occurs in three stages:

1. Surface degradation – Vibration loosens the surface layer, causing adhesion, elastic deformation, and metal transfer.

2. Oxidation & wear debris formation – Dislodged particles oxidize, forming an intermediate layer that further generates loose debris.

3. Accelerated wear – Fluid flow carries away loose particles, perpetuating the cycle until tube failure occurs.

II. Factors Influencing Wear Rate

1. Material Compatibility If tubes and baffles are the same material, wear rates are similar. Using harder baffle materials accelerates tube wear. Corrosion-resistant materials reduce long-term degradation.

2. Vibration Amplitude & Frequency Higher vibration amplitude and frequency increase wear due to greater kinetic energy. Larger gaps between tubes and baffles exacerbate impact and adhesive wear. 3. Geometric & Structural Factors Tube dimensions (wall thickness, diameter, boundary conditions) Baffle design (plate size, hole diameter, spacing) Material properties of tubes and baffles Experimental Insight: When wax fills the gap between tubes and baffles, vibration and noise decrease significantly. The wax reduces clearance and acts as a lubricant, mitigating wear.

III. Six Protective Measures to Reduce Wear

To minimize wear, the following strategies can be implemented:

Material Selection – Use insoluble metal pairs to limit adhesive wear.

Protective Coatings – Apply lubricants, surface films, or wear-resistant coatings.

Controlled Wear Conversion – Select materials that confine wear to acceptable levels of hardness, roughness, and contact resistance.

Gap Reduction – Decreasing the clearance between tubes and baffles by half can reduce wear rate by a factor of 1/103.

Anti-Vibration Inserts – Install strips, rods, plates, or wedges to suppress tube vibration.

Baffle Rod Heat Exchangers – These eliminate gaps between tubes, significantly reducing vibration-induced wear.