Selection and design points of expansion joints

Expansion joints are critical components in industrial systems that accommodate thermal expansion, vibration, and movement in piping and equipment. This comprehensive guide explores the technical aspects, material selection, and application considerations for expansion joints in various industrial settings.

Functions of Expansion Joints

Thermal Expansion Compensation

When temperature differentials cause asynchronous expansion between tube side (internal pipe) and shell side (external shell), expansion joints absorb length variations through flexible deformation, preventing structural damage from excessive stress.

Thermal Stress Reduction

Directly alleviates internal metal stress caused by temperature variations, preventing weld cracking, tube sheet deformation, or shell warping while protecting critical connection points.

Leak Prevention & Structural Integrity

Under extreme temperature fluctuations, uncompensated expansion can cause flange seal failure or pipe rupture. Expansion joints maintain sealing integrity through controlled deformation, reducing medium leakage risks.

Vibration & Displacement Absorption

Beyond thermal movement, expansion joints absorb mechanical vibration from fluid flow and installation misalignments, enhancing overall system stability and performance.

Equipment Life Extension

By minimizing alternating stress and fatigue damage, expansion joints reduce maintenance frequency and improve heat exchanger durability and operational economy.

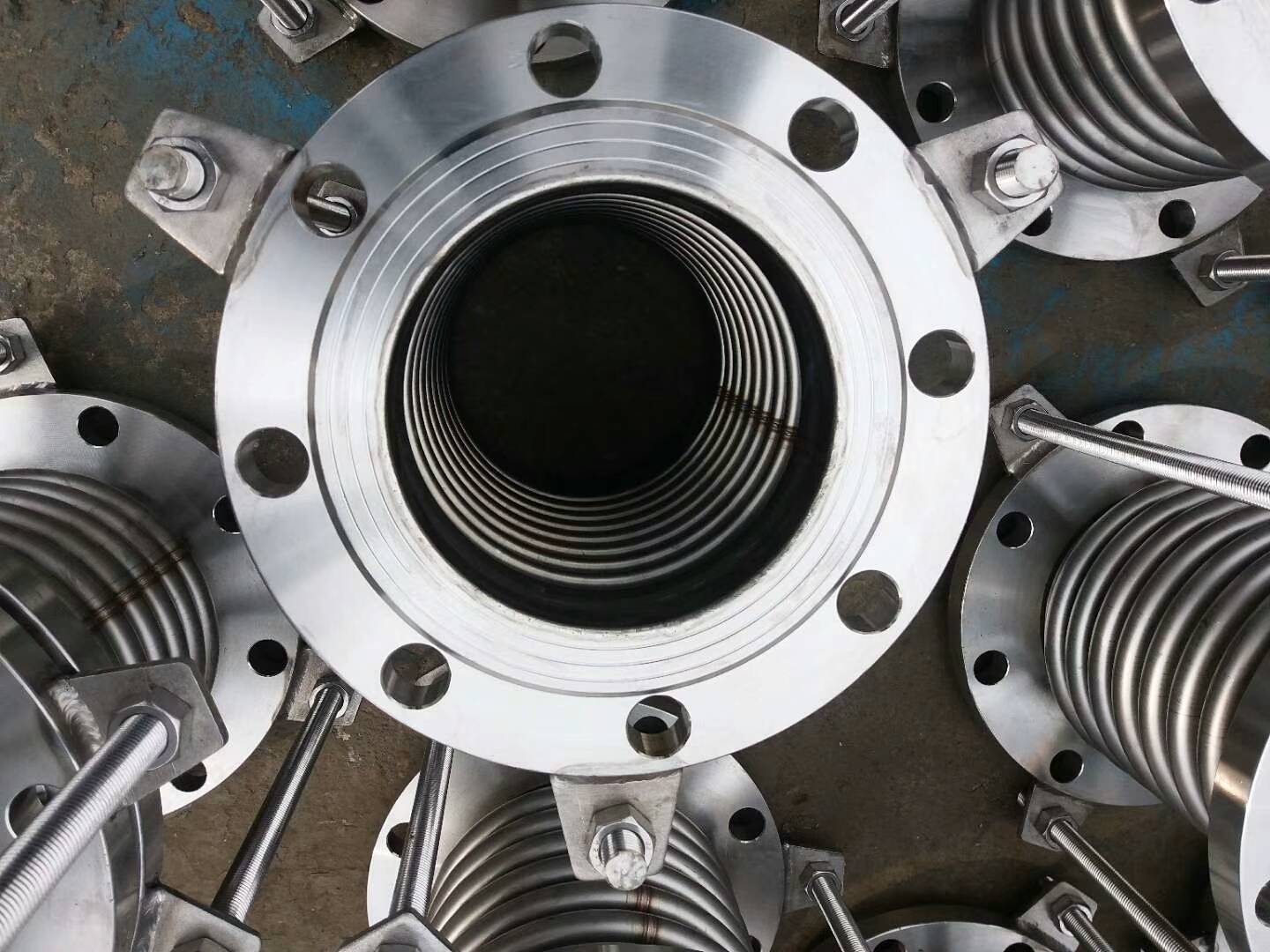

Material for Expansion Joints

Proper material selection is crucial for expansion joint performance, compensation capacity, and service life in specific operating environments.

| Material | Key Properties | Temperature Range | Pressure Rating | Applications |

|---|---|---|---|---|

| Stainless Steel | High temperature resistance, excellent corrosion resistance, high strength, long service life | -250°C to 800°C | Up to 1000 PSI | High-temperature steam lines, petrochemical applications, nuclear facilities |

| Rubber | Superior elasticity, vibration damping, noise reduction, easy installation | -50°C to 150°C | Up to 250 PSI | Water systems, HVAC, chemical pipelines (weak corrosives), vibration isolation |

| PTFE Composite | Exceptional chemical resistance, non-stick properties, flexibility | -70°C to 260°C | Up to 150 PSI | Aggressive chemical environments, pharmaceutical, food processing |

| Metal Bellows | Multi-layer construction, balanced flexibility and pressure capacity, large compensation range | -270°C to 1000°C | Up to 5000 PSI | High-pressure pipelines, thermal networks with large temperature differentials |

| Inconel Alloys | Extreme temperature resistance, oxidation resistance, maintains strength at high temperatures | -250°C to 1100°C | Up to 3000 PSI | Aerospace, gas turbines, high-temperature processing |

Material Performance Comparison

Expansion Joint Types and Configurations

Different expansion joint designs address specific movement requirements and installation constraints in piping systems.

| Type | Movement Capability | Key Features | Typical Applications |

|---|---|---|---|

| Single Axial | Axial compression/extension only | Compact design, cost-effective, single or few convolutions | Straight pipe runs with simple thermal expansion |

| Universal | Axial, lateral, and angular movement | Multiple bellows elements, handles complex movements | Systems with multi-directional movement requirements |

| Hinged | Pure angular rotation | Precise angular control, must be installed in sets | L-shaped or Z-shaped piping arrangements |

| Pressure Balanced | Axial movement while balancing pressure thrust | Internal flow bypass, eliminates pressure thrust on anchors | Equipment connections, pump inlets/outlets |

| Externally Pressurized | Axial compression | Bellows protected from internal pressure, resists squirm | High-pressure applications, vacuum systems |

| Tied/Untied Bellows | Lateral deflection with/without pressure thrust capacity | Control rods limit movement, handle pressure thrust | Applications where anchor loads must be minimized |

Expansion Joints Technical

Movement Capacity Factors

Axial Compression/Extension: Typically 10-100mm depending on bellows design

Lateral Deflection: Usually 20-200mm based on convolution geometry

Angular Rotation: Generally 1-10 degrees per hinge set

Cycle Life: 1,000 to 1,000,000 cycles based on movement magnitude and material

Installation

Pre-compression/Extension: Essential for thermal growth applications

Alignment: Critical to prevent binding and premature failure

Anchoring: Proper anchors required to absorb pressure thrust forces

Guiding: Guides necessary to control pipe movement direction

Expansion Joint Performance Data

Expansion Joints Industry Applications

| Industry | Primary Application | Recommended Type | Critical Factors |

|---|---|---|---|

| Power Generation | Steam turbine connections, boiler systems | Pressure balanced, universal | High temperature, pressure cycling, reliability |

| Petrochemical | Refinery piping, heat exchangers | Metal bellows, externally pressurized | Corrosion resistance, high pressure, safety |

| HVAC | Duct connections, equipment isolation | Rubber, fabric, single axial | Vibration isolation, noise reduction, cost |

| Marine | Engine exhaust, piping systems | Hinged, universal, rubber | Corrosion resistance, compact design, reliability |

| Pharmaceutical | Process piping, clean rooms | PTFE, stainless steel | Cleanability, chemical resistance, non-contaminating |