Why use finned tube for heat pump?

Why use finned tube for heat pump?

Finned tubes are commonly used in heat exchangers for various applications, including heat pumps. The primary purpose of finned tubes in a heat pump system is to enhance heat transfer efficiency between the refrigerant and the air or other heat transfer fluids. Heres how finned tubes are typically used in a heat pump:

1. Heat Exchange: In a heat pump, the refrigerant undergoes a cycle of compression and expansion to transfer heat from one location (the heat source) to another (the heat sink). Finned tubes are used as part of the heat exchanger coils within the heat pump system.

2. Heat Absorption: In the evaporator coil (the indoor unit), the refrigerant absorbs heat from the surrounding air. The finned tubes in the evaporator coil help increase the surface area for heat transfer. These fins create turbulence in the air, improving heat exchange and allowing the refrigerant to absorb heat more efficiently.

3. Heat Release: In the condenser coil (the outdoor unit), the refrigerant releases heat to the outside air. Again, finned tubes are used to enhance heat transfer by increasing the surface area. The refrigerant, now in a high-pressure state, releases its heat to the surrounding air, which is then blown away by a fan.

What type of finned tube will be used?

The type of finned tube used in a heat pump system depends on several factors, including the specific application, environmental conditions, and the design requirements of the system. Here are some common types of finned tubes used in heat pump applications:

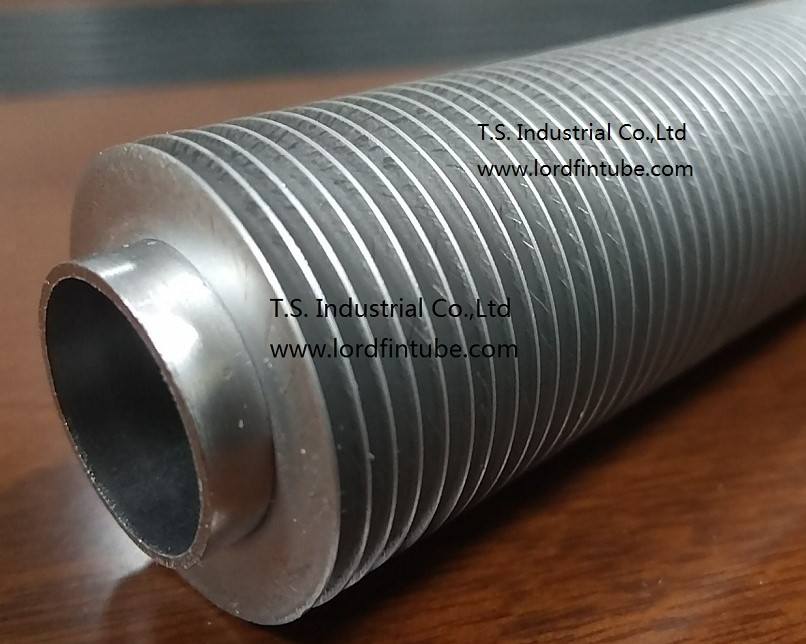

1. Plain Finned Tubes: These are basic tubes with smooth, straight fins attached to the outer surface. They are relatively simple in design and are suitable for applications with moderate heat transfer requirements.

2. Corrugated Finned Tubes: Corrugated fins have a wavy or zigzag pattern. They increase the heat transfer surface area and can be more effective than plain fins in some applications. They are often used when enhanced heat transfer is needed.

3. Louvered Finned Tubes: Louvered fins have a design that resembles the blades of a louvered shutter. They provide efficient heat transfer and are resistant to fouling. They are commonly used in air-cooled condensers and evaporators.

4. Perforated Finned Tubes: These finned tubes have small perforations in the fins. They are often used in applications where frost or ice buildup is a concern because the perforations help prevent ice formation and improve defrosting.

5. Serrated Finned Tubes: Serrated fins have a serrated or toothed edge. This design enhances turbulence in the air, improving heat transfer efficiency. Serrated finned tubes are often used in high-efficiency heat exchangers.

6. Spine Finned Tubes: Spine fins consist of a central spine with smaller fins extending outward. This design provides high surface area and good heat transfer performance. Spine finned tubes are suitable for demanding heat pump applications.

7. Twisted Finned Tubes: Twisted fins are designed with a helical or twisted shape. This design creates swirling air patterns, which can enhance heat transfer efficiency. Twisted finned tubes are used in various heat exchanger applications.

8. Extruded Finned Tubes: Extruded fins are created by extruding fins from the base tube material. They provide excellent heat transfer performance and are often used in industrial heat exchangers.

The choice of finned tube type depends on factors such as the required heat transfer rate, operating conditions (temperature and pressure), the presence of contaminants or fouling agents, and the available space for the heat exchanger. Additionally, the choice of material for the finned tubes (e.g., aluminum, copper) should be considered based on factors like thermal conductivity and corrosion resistance.

Ultimately, the selection of the most appropriate finned tube type should be made based on a thorough analysis of the specific heat pump systems requirements and design parameters. Consulting with a heat exchanger or HVAC system engineer is often necessary to make the best choice for a given application.

Finned tubes come in various designs and materials, depending on the specific requirements of the heat pump system. Common materials include aluminum and copper, which have good thermal conductivity properties. The fins on the tubes can have different shapes, such as straight or corrugated, and can be spaced at various intervals to optimize heat transfer.

The selection of finned tubes depends on factors like the heat pumps capacity, the desired efficiency, the operating conditions (temperature and pressure), and the compatibility with the refrigerant used in the system.

In summary, finned tubes play a crucial role in heat pump systems by increasing the efficiency of heat exchange between the refrigerant and the surrounding air, helping to transfer heat from one location to another in the heating or cooling process.