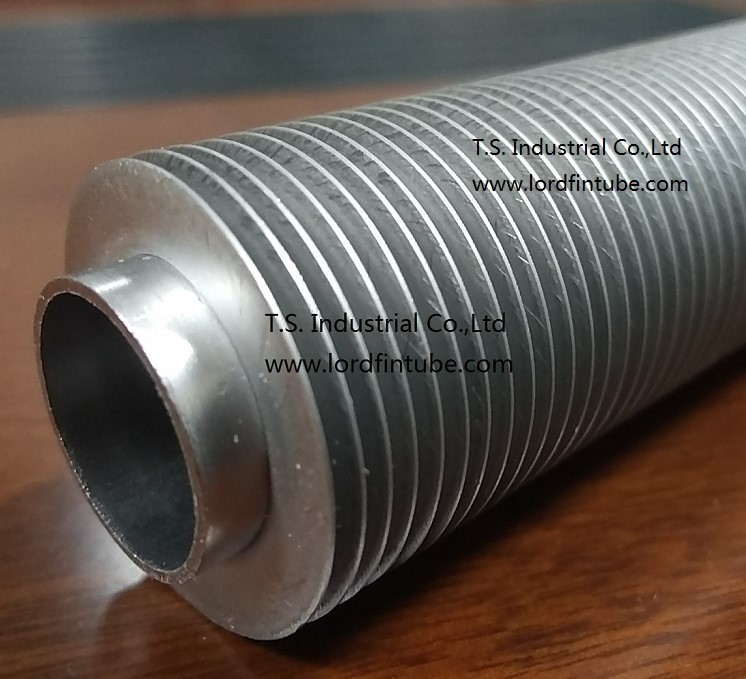

Lord Fin Tube--Laser welded stainless finned tube

Laser-welded stainless steel finned tubes are advanced heat transfer components designed for high efficiency and durability. Utilizing TP316L base tubes and fin strips from stainless steel grades like 304, 316, 1.4301, 1.4404, and 1.4521, these tubes benefit from a precise laser welding technique that ensures a 100% welding rate. This method significantly enhances heat transfer capacity and corrosion resistance while minimizing heat-affected zones. Available in various dimensions and lengths, these tubes are versatile for applications in the chemical, power, heat recovery, and heating industries, offering superior performance and longevity.

Laser-welded stainless steel finned tubes Materials

Base Tube Materials:

- TP316L (Primary)

- Stainless Steel 304, 316, 1.4404, 1.4301, 1.5471

Fin Strip Materials:

- Stainless Steel 304, 316, 1.4301, 1.4404, 1.4521

Laser-welded stainless steel finned tubes Features

- Welding Rate: 100%

- Heat Transfer: Sharply increased, up to 2.5 times higher thermal performance

- Anti-Corrosion: High resistance due to continuous weld

- Heat-Affected Zone: Minimal, with high-speed travel up to 20 m/min

- Weld Integrity: Avoids crevice corrosion

- Protective Atmosphere: Ensures impurity-free welds

Laser-welded stainless steel finned tubes Technical Specifications

Sample Tube Dimensions:

- Tube: 22 x 2.0 mm

- Fin: 0.4 mm thickness, 7 mm height, 11 fins per inch

- Lengths: 50 cm to >10 meters

General Dimensions:

- Tube Outside Diameter: 8.0–50.0 mm

- Fin Outside Diameter: 17.0–80.0 mm

- Fin Pitch: 5–13 fins/inch

- Fin Height: 5.0–17 mm

- Fin Thickness: 0.4–1.0 mm

- Maximum Tube Length: 12.0 m

Laser-welded stainless steel finned tubes Advantages

- Heat Transfer: Excellent due to complete connection between fins and base tube

- Corrosion Resistance: Enhanced, suitable for oscillating applications

- Safety: Avoids crevice corrosion with high weld integrity

- Welding Quality: Thin, continuous weld seam with minimal discoloration and microstructural change

- Efficiency: High utilization of heat for forming the seam

- Purity: No weld seam impurities due to protective atmosphere during laser welding

Laser-welded stainless steel finned tubes Applications

Power Plants:

- Cooling towers or cooling water recooling plants

- Flue gas cooling and heating in desulfurization scrubbers and nitrogen removing plants

Chemical Industry:

- Various heat exchangers for cooling and heating liquids and gases

- Heat exchangers for nitric acid plants in the fertilizer industry

Heat Recovery Plants:

- Flue gas coolers

Heating Industry:

- Primary heat exchangers in gas heating boilers

- Secondary heat exchangers for domestic water heating in condensing boilers

General Engineering:

- Heat exchangers for gas cooling of industrial furnaces

- Tank heating heat exchangers

- Oil coolers for vacuum plants, ship plants, pumps, etc.

- Oil preheating heat exchangers

Laser-welded stainless steel finned tubes offer superior heat transfer and corrosion resistance, making them suitable for diverse industrial applications. The high precision and quality of laser welding ensure durability and performance in demanding environments.