LL-Foot Finned Tube VS L-Foot Finned Tube

2024-04-22Leave a message

LL-foot finned tubes and L-foot finned tubes are two common types of finned tubes used in various heat transfer applications. LL-Foot Finned Tubes provide larger surface area and higher heat transfer efficiency, ideal for applications requiring maximized heat exchange, while L-Foot Finned Tubes offer advantages in space constraints or fluid flow considerations.

1. LL-Foot Finned Tube VS L-Foot Finned Tube in Footing Design:

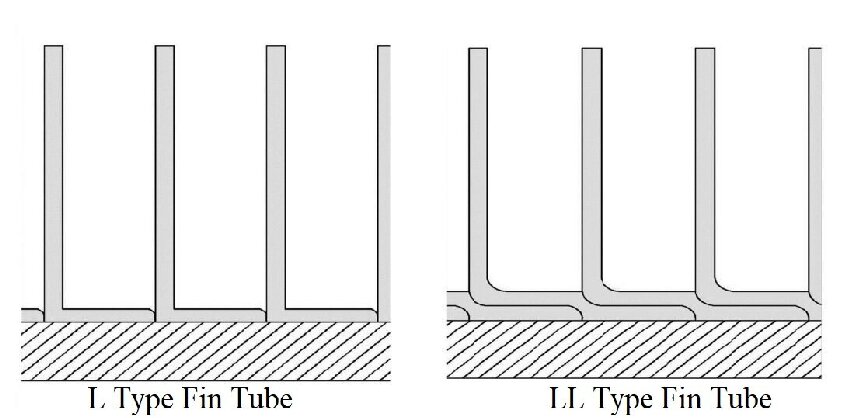

- LL-Foot Finned Tube: LL-foot finned tubes have a unique "double L" shape. The fins are folded over and attached to the base tube in the shape of two perpendicular Ls, hence the name LL-foot.

- LL-foot finned tubes have two layers of L-shaped fins. The second L-fin is wrapped over the first, providing an additional layer of protection and coverage.

This double layer increases the overall strength and durability of the finned tube.

- L-Foot Finned Tube: L-foot finned tubes have a simpler design, with fins shaped like a single L attached to the base tube. The fin extends outward from the tube surface in one direction.

- L-foot finned tubes have a single layer of L-shaped fins wrapped around the tube.

- The fin foot (base) is in direct contact with the tube surface, providing good heat transfer.

2. LL-Foot Finned Tube VS L-Foot Finned Tube in Surface Area:

- LL-Foot Finned Tube: LL-foot finned tubes typically provide a larger surface area compared to L-foot finned tubes due to their double L-shaped fins.

- L-Foot Finned Tube: L-foot finned tubes have a relatively smaller surface area as they feature a single fin per tube.

3. LL-Foot Finned Tube VS L-Foot Finned Tube in Heat Transfer Efficiency:

- LL-Foot Finned Tube: LL-foot finned tubes generally offer higher heat transfer efficiency owing to their larger surface area, facilitating better heat exchange between the fluid inside the tubes and the surrounding medium (air or liquid).

- L-Foot Finned Tube: While still effective, L-foot finned tubes may have slightly lower heat transfer efficiency compared to LL-foot finned tubes due to their smaller surface area.

4. LL-Foot Finned Tube VS L-Foot Finned Tube in Fluid Flow Characteristics:

- LL-Foot Finned Tube: LL-foot finned tubes may induce higher fluid turbulence due to their larger surface area and fin configuration, potentially enhancing heat transfer but also increasing pressure drop.

- L-Foot Finned Tube: L-foot finned tubes typically induce less fluid turbulence compared to LL-foot finned tubes, resulting in lower pressure drop but potentially slightly lower heat transfer efficiency.

5. LL-Foot Finned Tube VS L-Foot Finned Tube in Applications:

- LL-Foot Finned Tube: LL-foot finned tubes are often preferred in applications where maximizing heat transfer efficiency is crucial, such as air pre-heaters, heat exchangers, and refrigeration systems.

- Used in environments with higher risk of corrosion or mechanical damage. Suitable for applications requiring higher heat transfer efficiency and durability.

- L-Foot Finned Tube: L-foot finned tubes are suitable for applications where space constraints or fluid flow considerations favor a more streamlined design with lower pressure drop.

- Commonly used in less harsh environments where extreme durability is not a primary concern.Suitable for general-purpose heat exchangers and applications with standard heat transfer requirements.

LL-foot finned tubes generally offer higher heat transfer efficiency and larger surface area compared to L-foot finned tubes, making them preferable for applications where maximizing heat exchange is paramount. However, the choice between the two ultimately depends on specific application requirements such as space limitations, fluid flow characteristics, and desired heat transfer performance.