What are longitudinal finned tubes?

What are longitudinal finned tubes?

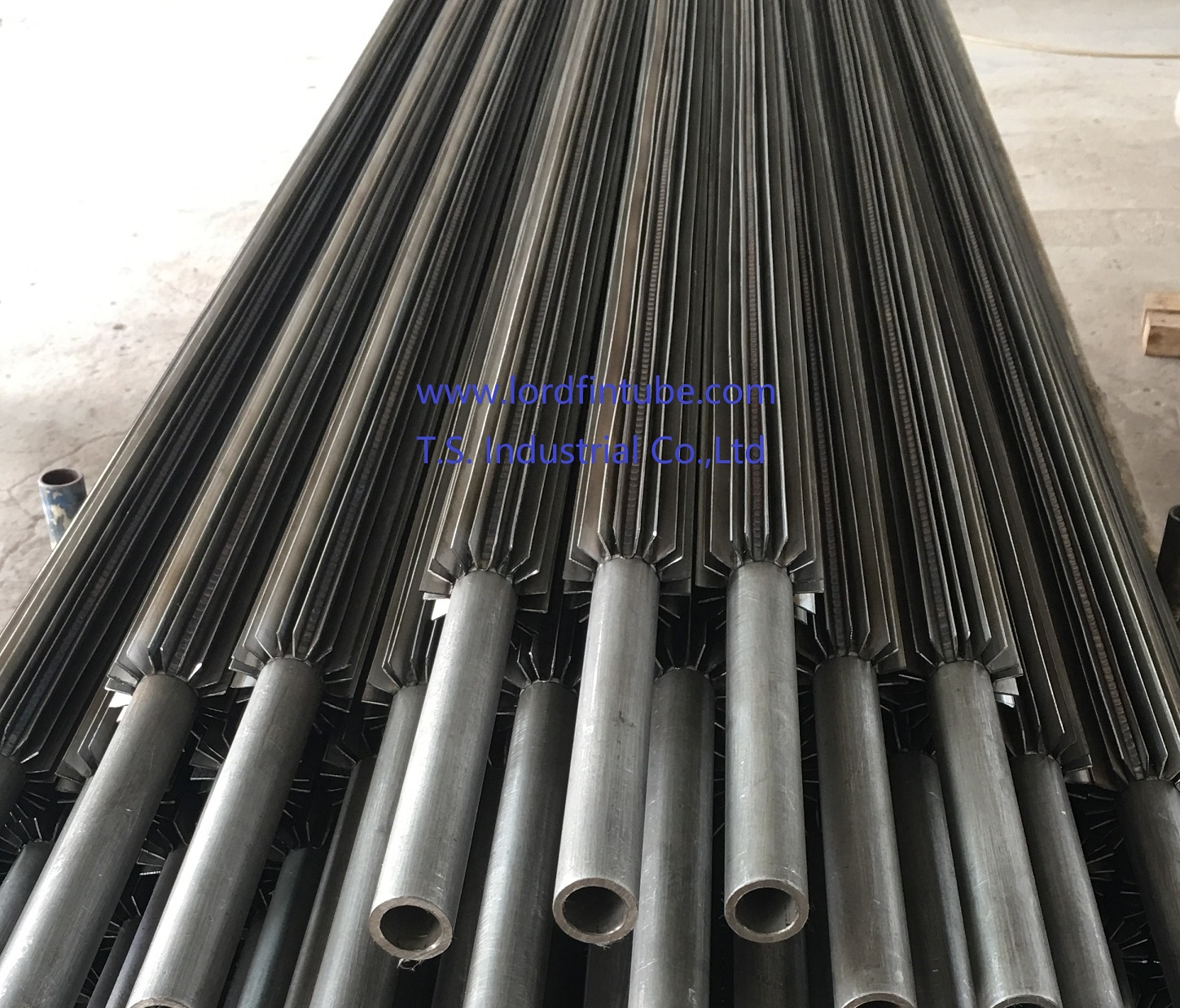

Longitudinal finned tubes are heat transfer components used in various industrial applications where efficient heat transfer is required. These tubes are made up of a base tube, which is usually made of steel, stainless steel, or copper, and longitudinal fins, which are attached to the outer surface of the base tube.

The fins increase the surface area of the tube, which enhances the heat transfer rate by improving the convective heat transfer coefficient. The longitudinal fin design provides a more significant surface area than the radial fin design, which makes it more suitable for high-temperature applications.

Longitudinal finned tubes are commonly used in heat exchangers, boilers, and air coolers. They are also used in some chemical processes, such as oil refining and petrochemical manufacturing.

The design of longitudinal finned tubes is critical, as it affects the overall efficiency of the heat transfer system. The size, shape, and material of the fins should be carefully selected based on the operating conditions of the system. Factors such as fluid velocity, temperature, and pressure drop should also be considered during the design process.

In summary, longitudinal finned tubes are a crucial component in various heat transfer applications, providing improved efficiency and performance.

Longitudinal Finned Tubes advantage compare with helical finned tubes

Both longitudinal and helical finned tubes are used to enhance heat transfer rates in industrial applications. However, there are some advantages of longitudinal finned tubes compared to helical finned tubes:

1. Higher surface area: Longitudinal finned tubes have a larger surface area compared to helical finned tubes, resulting in improved heat transfer efficiency.

2. Better heat transfer performance: The longitudinal fin design provides more significant contact between the fins and the fluid, resulting in better heat transfer performance.

3. Resistance to fouling: Longitudinal finned tubes are less susceptible to fouling compared to helical finned tubes because of their smooth, straight fins. This property reduces maintenance costs and increases the overall lifespan of the tubes.

4. Easy to manufacture: Longitudinal finned tubes are easier to manufacture compared to helical finned tubes, which require a more complex manufacturing process.

5. More suitable for high-temperature applications: The longitudinal fin design provides a larger surface area, making them more suitable for high-temperature applications, where the heat transfer rate needs to be maximized.

In summary, longitudinal finned tubes offer advantages over helical finned tubes in terms of higher surface area, better heat transfer performance, resistance to fouling, ease of manufacturing, and suitability for high-temperature applications. However, the choice between the two types of finned tubes ultimately depends on the specific requirements of the application.