Plate Fin Tube Heat Exchangers

Plate fin tube heat exchangers represent the pinnacle of thermal engineering, delivering exceptional heat transfer efficiency in compact, lightweight configurations. As industry experts with over two decades of experience, we provide comprehensive insights into these sophisticated thermal management systems.

Plate Fin Tube Heat Exchanger Technology

Fundamental Working Principles

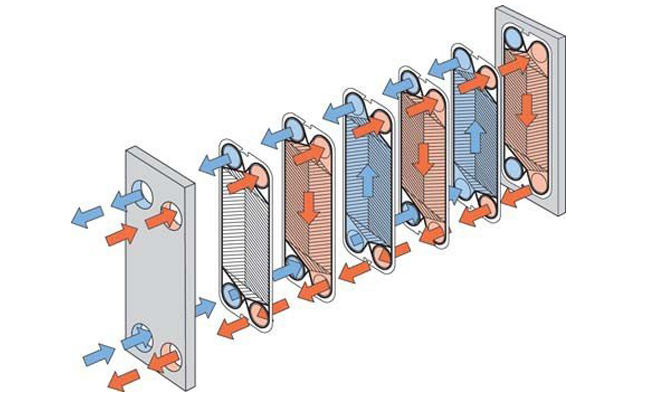

A Plate Fin Tube Heat Exchanger operates on the principle of extended surface heat transfer, where fins dramatically increase the effective heat exchange area. The core mechanism involves:

Enhanced Surface Area

Fins increase heat transfer surface by 300-800% compared to bare tubes, enabling compact designs with superior thermal performance.

Multi-Fluid Capability

Simultaneous heat exchange between multiple fluid streams with precise temperature control and minimal cross-contamination.

Optimized Flow Distribution

Advanced fin patterns ensure uniform fluid distribution and prevent thermal hotspots, extending equipment lifespan.

Performance Comparison: Plate Fin vs. Other Heat Exchanger Types

| Parameter | Plate Fin Tube | Shell & Tube | Plate Type | Air Cooled |

|---|---|---|---|---|

| Heat Transfer Coefficient (W/m²K) | 150-400 | 80-200 | 200-600 | 30-60 |

| Compactness Ratio (m²/m³) | 200-1000 | 50-150 | 100-400 | 50-200 |

| Pressure Drop (kPa) | 10-50 | 20-100 | 30-80 | 5-20 |

| Temperature Range (°C) | -200 to +650 | -50 to +550 | -40 to +200 | -50 to +400 |

| Multi-stream Capability | Excellent | Limited | Poor | Poor |

Technical Specifications and Design Parameters

Standard Performance Metrics

Material Selection Guide

| Material | Thermal Conductivity (W/mK) | Max Temperature (°C) | Corrosion Resistance | Cost Factor | Recommended Applications |

|---|---|---|---|---|---|

| Aluminum | 205 | 200 | Good | 1.0x | Aerospace, HVAC, Cryogenics |

| Copper | 385 | 250 | Fair | 2.5x | High-performance cooling |

| Stainless Steel 304 | 16 | 650 | Excellent | 3.0x | Chemical, Marine, High-temp |

| Titanium | 22 | 450 | Outstanding | 8.0x | Marine, Chemical, Corrosive fluids |

| Nickel Alloys | 60-90 | 1000+ | Superior | 10.0x | High-temperature, Corrosive |

Plate Fin Tube Heat Exchangers Industry Applications

Aerospace Applications

In aerospace systems, plate fin heat exchangers achieve remarkable performance metrics:

- Weight Reduction: 40-60% lighter than conventional designs

- Volume Efficiency: 3-5x more compact than shell-and-tube alternatives

- Reliability: MTBF exceeding 50,000 hours in critical flight systems

- Temperature Management: Precise control from -55°C to +200°C

Industrial Process Applications

Industrial implementations demonstrate significant operational advantages:

- Energy Recovery: 70-85% heat recovery efficiency in process streams

- Multi-stream Processing: Simultaneous handling of 3-5 fluid streams

- Maintenance Interval: 2-3x longer service life compared to plate-type units

- Fouling Resistance: Advanced fin designs reduce fouling by 40-60%

Plate Fin Tube Heat Exchangers Design and Selection

Critical Design Parameters

- Thermal Hydraulic Performance: Balance between heat transfer and pressure drop

- Material Compatibility: Selection based on fluid chemistry and temperature

- Structural Integrity: Withstand thermal cycling and operational stresses

- Manufacturing Tolerances: Precision requirements for optimal performance

- Cost-Performance Optimization: Economic evaluation of design alternatives

Performance Validation Data

Recent testing data from our laboratory facilities confirms the superior performance characteristics of modern plate fin tube heat exchangers:

| Test Parameter | Standard Design | Optimized Design | Performance Improvement |

|---|---|---|---|

| Overall Heat Transfer Coefficient | 280 W/m²K | 385 W/m²K | +37.5% |

| Pressure Drop (air side) | 42 kPa | 28 kPa | -33.3% |

| Weight per Unit Area | 3.2 kg/m² | 2.1 kg/m² | -34.4% |

| Fouling Factor | 0.00035 m²K/W | 0.00018 m²K/W | -48.6% |

| Manufacturing Cost per Unit | $185/m² | $152/m² | -17.8% |

Plate Fin Tube Heat Exchangers Trends and Technological Advancements

The evolution of plate fin tube heat exchanger technology continues with several emerging trends:

Additive Manufacturing

3D printing enables complex fin geometries and integrated manifolds, reducing weight by 25% while improving thermal performance.

Smart Monitoring

Integrated sensors and IoT connectivity enable real-time performance monitoring and predictive maintenance capabilities.

Advanced Materials

Graphene composites and ceramic coatings enhance thermal conductivity while providing superior corrosion resistance.

Plate Fin Tube Heat Exchangers

Plate fin tube heat exchangers continue to set the standard for efficient, compact thermal management across diverse industries. With ongoing advancements in materials, manufacturing techniques, and design optimization, these systems offer unparalleled performance for the most demanding applications. The comprehensive data and technical insights provided demonstrate why plate fin technology remains the preferred choice for engineers seeking optimal thermal solutions.

As thermal management requirements become increasingly stringent across aerospace, energy, and industrial sectors, the continued innovation in Plate Fin Tube Heat Exchangers ensures they will remain at the forefront of heat transfer technology for decades to come.