Lord Fin Tube--Studded tubes manufacturer

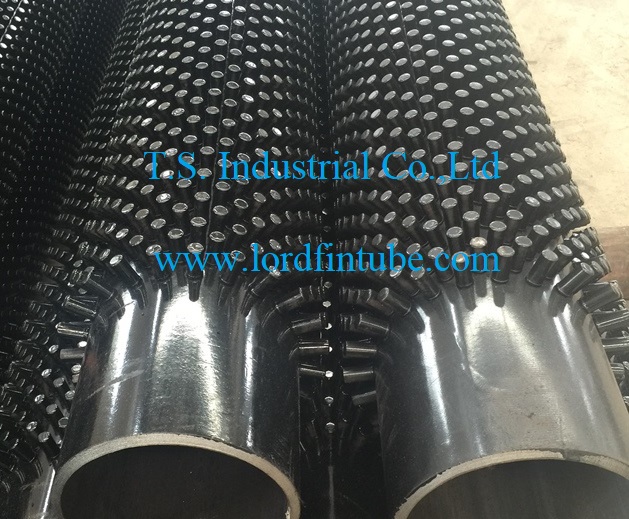

Studded tubes (also known as stud-welded tubes or pin pipes) are specialized heat transfer surfaces engineered to maximize thermal efficiency in demanding industrial applications. As a leading studded tube manufacturer, we provide comprehensive technical insights into these high-performance components.

1. Studded Tubes Definition & Core Applications

Studded tubes are steel pipes with externally welded studs or protrusions, typically manufactured from carbon steel, stainless steel (AISI 304/316/410), or specialty alloys (Inconel, Monel, Hastelloy). These studs significantly enhance surface area and functional performance for critical industrial applications.

Studded Tubes Industrial Applications

Heat Transfer Enhancement

Optimizes thermal efficiency in boilers, heat exchangers, and furnaces by disrupting laminar flow and increasing turbulence.

Abrasion/Wear Resistance

Protects pipelines handling abrasive materials in fluidized beds, cement kilns, and mining operations.

High-Temp/Pressure Environments

Ideal for petrochemical, power generation, and shipbuilding industries with extreme operating conditions.

Anti-Fouling Solutions

Reduces sediment buildup in chemical processing and wastewater treatment applications.

2. Studded Tubes Features & Technical Advantages

Structural Design Excellence

Stud Arrangement: Precision-engineered staggered rings or helical patterns tailored to maximize heat transfer or wear resistance based on specific application requirements.

Dual-Surface Design: Smooth inner bore minimizes pressure drop while studded exterior enhances thermal performance and mechanical durability.

Performance Benefits Analysis

| Feature | Technical Advantage | Performance Data |

|---|---|---|

| Heat Transfer Efficiency | Superior thermal performance through increased surface area and optimized turbulence generation | 30-50% higher efficiency vs. bare tubes; Up to 3.2x surface area increase |

| Abrasion Resistance | Extended service life in particle-laden flows and erosive environments | 2-3x longer lifespan in coal-fired boilers and fluidized bed applications |

| Anti-Fouling Properties | Reduces sediment and deposit accumulation, minimizing maintenance downtime | 40-60% reduction in cleaning frequency and associated operational costs |

| Mechanical Strength | Robust construction withstands extreme operational conditions | Pressures up to 150 bar; Temperatures exceeding 800°C |

| Corrosion Resistance | Material-specific protection against chemical and environmental degradation | Compatible with acidic, alkaline, and saline environments |

Surface Area Increase

Compared to smooth tubes

Heat Transfer Boost

Enhanced thermal efficiency

Service Life

Longer than standard tubes

Pressure Rating

Maximum operating pressure

3. Studded Tubes Materials & Manufacturing Process

Material Selection Guide

| Material Type | Best Applications | Temperature Range | Key Advantages |

|---|---|---|---|

| Carbon Steel | General-purpose applications, cost-sensitive projects | -20°C to 450°C | Cost-effective, good mechanical properties |

| Stainless Steel 304/316 | Chemical processing, food industry, marine applications | -200°C to 800°C | Excellent corrosion resistance, hygienic |

| Stainless Steel 410 | High-temperature applications, thermal cycling | Up to 650°C | Good heat resistance, moderate corrosion resistance |

| Nickel Alloys (Inconel) | Extreme environments, sulfuric acid recovery, aerospace | Up to 1100°C | Superior heat and corrosion resistance |

| Duplex Stainless Steel | Offshore, chemical processing with chlorides | -50°C to 300°C | Excellent strength and corrosion resistance |

Advanced Manufacturing Techniques

Automated Stud Welding

Precision drawn-arc or resistance welding ensures strong, consistent metallurgical bonds with minimal heat-affected zones.

Base Tube Fabrication

Seamless or welded tubes with OD range: 60.3-219 mm; Custom lengths up to 20 meters based on application requirements.

Comprehensive Quality Control

NDT Testing: X-ray/ultrasonic inspection for weld integrity; Pressure testing validates performance under operational conditions.

4. Studded Pipes Technical Specifications

| Parameter | Range/Capability | Standards Compliance | Testing & Certification |

|---|---|---|---|

| Tube Outer Diameter | 60.3-219 mm (custom sizes available) | ASTM A213, ASME SA192, EN 10216 | Dimensional inspection, visual examination |

| Stud Height | 6-25 mm (fully customizable based on application) | ISO 9001, customer specifications | Height verification, consistency checks |

| Pressure Rating | Up to 150 bar (design dependent) | PED 2014/68/EU, ASME BPVC | Hydrostatic testing, burst testing |

| Temperature Range | -50°C to +800°C (material-dependent) | EN 10204 3.1 Certification | Material certification, thermal cycling tests |

| Stud Diameter | 3-12 mm (standard range) | Customer specifications, application requirements | Dimensional accuracy, weld penetration checks |

| Stud Pattern | Staggered, inline, helical (custom configurations) | Technical drawings, application optimization | Pattern verification, stud count accuracy |

| Surface Finish | As-welded, ground, pickled, polished | ASTM A480, customer requirements | Surface roughness measurement, visual standards |

5. Studded Tubes Industry Applications

Sector-Specific Applications

Power Generation

Boiler superheaters, economizers in coal/gas-fired plants; Waste heat recovery systems improving energy efficiency by 15-20%.

Oil & Gas

Refinery reheaters, sulfur condensers, heat exchangers in upstream and downstream processing facilities.

Chemical Processing

Reactors, acid-cooling pipelines resistant to H₂SO₄/HCl atmospheres; Polymerization and condensation reactors.

Metallurgy

High-temperature flue gas ducts reducing erosion in sintering plants; Heat recovery in furnace applications.

Compatible Equipment

- Shell-and-tube heat exchangers

- Fluidized bed reactors

- Thermal oxidizers

- Waste heat boilers

- Air preheaters

- Process heaters

6. Selection Guide: Choosing the Right Studded Tube

Key Selection Criteria

When specifying studded tubes for your application, consider these critical factors:

Operating Temperature

Determines material selection and stud configuration

Pressure Requirements

Affects tube wall thickness and stud weld strength

Fluid Characteristics

Corrosiveness, abrasiveness, and fouling potential

Thermal Performance

Required heat transfer efficiency and pressure drop limits

Performance Comparison: Studded Tubes vs. Alternatives

| Parameter | Studded Tubes | Bare Tubes | Finned Tubes |

|---|---|---|---|

| Heat Transfer Efficiency | High (30-50% improvement) | Baseline | High (similar to studded) |

| Abrasion Resistance | Excellent | Poor | Poor to Fair |

| Fouling Resistance | Good to Excellent | Poor | Fair |

| Mechanical Strength | Excellent | Good | Fair to Good |

| Cost Efficiency | High (long-term) | Low (initial) | Medium |

| Maintenance Requirements | Low | Medium to High | Medium |