Tube sheets are manufactured from various materials to suit specific service conditions, including carbon steel (ASTM A105, A266 Cl.2/4), low-temperature carbon steel (ASTM A350 LF2/LF3), and high-yield carbon steel (ASTM A694 F52-F70) for sour service. Stainless steel options (ASTM A182 F304/L, F316/L, F321/H) provide corrosion resistance, while duplex stainless steels (F51, F53) offer enhanced strength and pitting resistance. Low alloy steels (ASTM A182 F11, F22, F91) are used for high-temperature/pressure applications, and nickel alloys (Alloy 20, 625) or copper alloys (Naval Brass C4640, Aluminum Bronze C6300) address specialized corrosive environments. Material selection depends on temperature, pressure, corrosion risks, and compliance with ASME BPVC and TEMA standards.

Tube Sheet Materials and Specifications

1. Carbon Steel

| Standard |

Grade/Class |

Properties |

Applications |

| ASTM A105 |

N/A |

Forged carbon steel, non-normalized |

Flanges, fittings, non-corrosive services |

| ASTM A266 |

Cl. 2 (Normalized)

Cl. 4 (Q&T) |

Pressure vessel quality |

High strength applications |

2. Baffle Plate Materials

| Material |

Standard |

Properties |

| Carbon Steel |

ASTM A36 |

3-200mm thickness range |

| Martensitic SS |

SS440 (A/B/C) |

Up to 58 HRC hardness |

| Pressure Vessel Steel |

ASTM A516 Gr.60/70 |

Yield: 220-260 MPa |

3. Low-Temperature Carbon Steel

| Standard |

Grade |

Temperature Rating |

| ASTM A350 |

LF2 |

-46°C |

| LF3 |

-101°C |

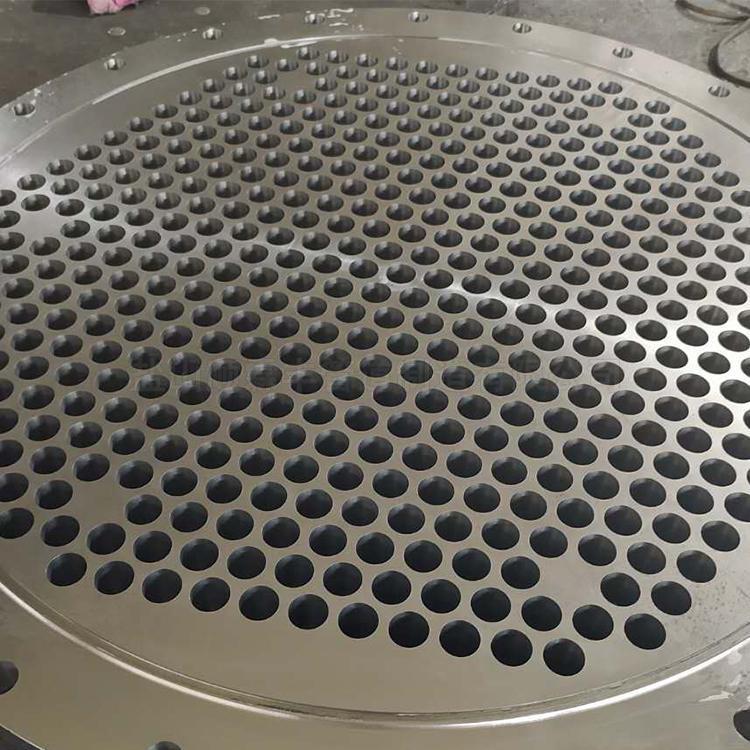

Tube Sheet Design & Fabrication Specifications

Governing Codes

- ASME BPVC (2007 Ed.): Sections II, V, VIII (Div. 1/2/3)

- TEMA 9th Ed. (2007): Class R/C/B

Dimensional Tolerances

| Parameter |

Tolerance |

Standard |

| Flatness |

≤0.5 mm/m |

TEMA Table D-5 |

| Hole Diameter |

±0.05 mm |

For expanded tubes |

-

Tube Sheet / Girth Flange:Maximum OD 5,000mm x 500mm thickness, Maximum 25 Tonne

- Forged Nozzle:Maximum weight 25 Tonne

Forged Tubesheet