Lord Fin Tube-Finned Tube manufacturer

Global Finned Tube Manufacturers

Advanced heat transfer solutions from world-leading manufacturers

Global Finned Tube Manufacturers

There are several manufacturers globally that specialize in producing finned tubes for various industrial applications. These companies provide advanced heat transfer solutions for industries ranging from power generation to HVAC systems.

Wieland Thermal Solutions

- Leading manufacturer of finned tubes

- Serves HVAC, refrigeration, and power generation industries

- Global presence with innovative solutions

- High-quality materials and precision engineering

Trufin Tubes Pvt. Ltd.

- Indian manufacturer of high-quality finned tubes

- Specializes in heat transfer applications

- Serves petrochemical, chemical, and power generation industries

- Custom solutions for challenging environments

Thermatool Corp.

- Specializes in design and manufacturing of finned tubes

- Serves oil and gas, petrochemical, and power generation

- Innovative heat transfer equipment solutions

- Focus on efficiency and durability

Superior Tube Products Inc.

- Manufactures precision-engineered finned tubes

- Applications include heat exchangers, boilers, and air coolers

- High-performance solutions for demanding industries

- Focus on quality and reliability

Vulcan Finned Tubes

- Expert in producing finned tubes

- Specializes in air coolers and heat exchangers

- Serves industrial heating and cooling systems

- Robust solutions for harsh environments

Precision Tube Company

- Specializes in high-quality finned tubes

- Serves aerospace, automotive, and power generation

- Precision engineering for critical applications

- Innovative solutions for complex heat transfer needs

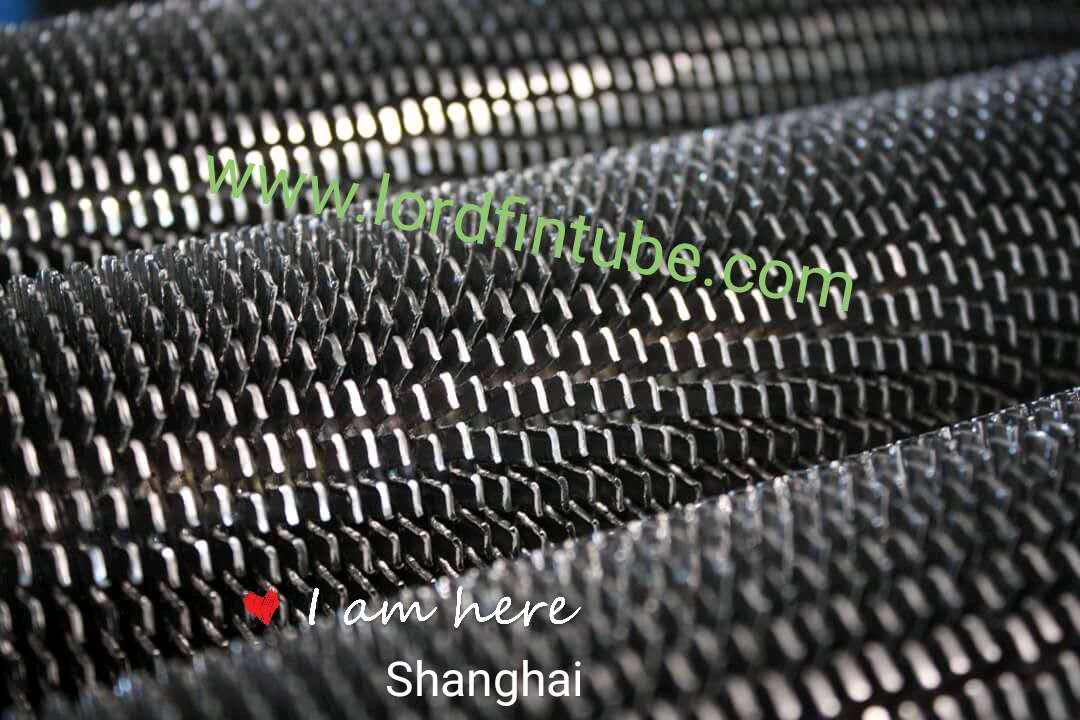

Shanghai T.S. Industrial Co., Ltd. (Lord Fin Tube)

Shanghai T.S. Industrial Co., Ltd. (Lord Fin Tube) is a leading Chinese manufacturer that supplies finned tubes for applications in heating, ventilation, air conditioning, and refrigeration (HVACR) systems, as well as other industrial applications.

Lord Fin Tube Product Range

High Frequency Welding Finned Tube

The company has 6 automatic production lines with an annual output of 2000 tons. Products meet Hg/t3181 and JB/t6512 standards.

Learn moreL-type & Double-L Finned Tube

Uses CNC machines for consistent bonding. Trapezoidal cross-section improves thermal efficiency by matching heat flow density.

Learn moreKLM Finned Tube

Base tube knurled outside with rolled L-shaped aluminum fins. Contact area increased by 50% with minimal thermal resistance.

Learn moreBimetallic Rolling Finned Tube

Special equipment rolls fins on aluminum tubes with 4x contact pressure. Allows medium temperatures up to 350°C.

Learn moreEmbedded Finned Tube

Uses McElroy equipment with advanced slotting technology. Pull-out force ≥70N, medium temperature up to 400°C.

Learn moreBrazed Finned Tube

100% bonding rate with nickel base layer. Resistant to high/low temperature corrosion and wear. No ash/scale deposition.

Learn moreElliptical Winding Finned Tube

Patented product with strong winding process. Increases heat transfer coefficient by 25% and reduces air resistance by 15-25%.

Learn moreRectangular Elliptical Fin Tube

High-speed stamping with hot-dip galvanizing. Stable fin spacing and uniform zinc layer. Ideal for power station applications.

Learn moreOuter Longitudinal Finned Tube

High frequency welding with U-shaped fins. Fin ratio >10. Ideal for petrochemical shell and tube heat exchangers.

Learn moreStainless Steel Finned Tube

Nickel brazing or high frequency welding. 100% welding rate, working temperature 800°C. For harsh environments.

Learn moreWhy Choose Lord Fin Tube?

Quality Assurance

All products meet international standards with rigorous quality control at every production stage.

Advanced Technology

State-of-the-art manufacturing facilities with automated production lines and precision engineering.

Global Reach

Products shipped worldwide with comprehensive support and service networks in key markets.

Custom Solutions

Tailored designs to meet specific application requirements and challenging environments.