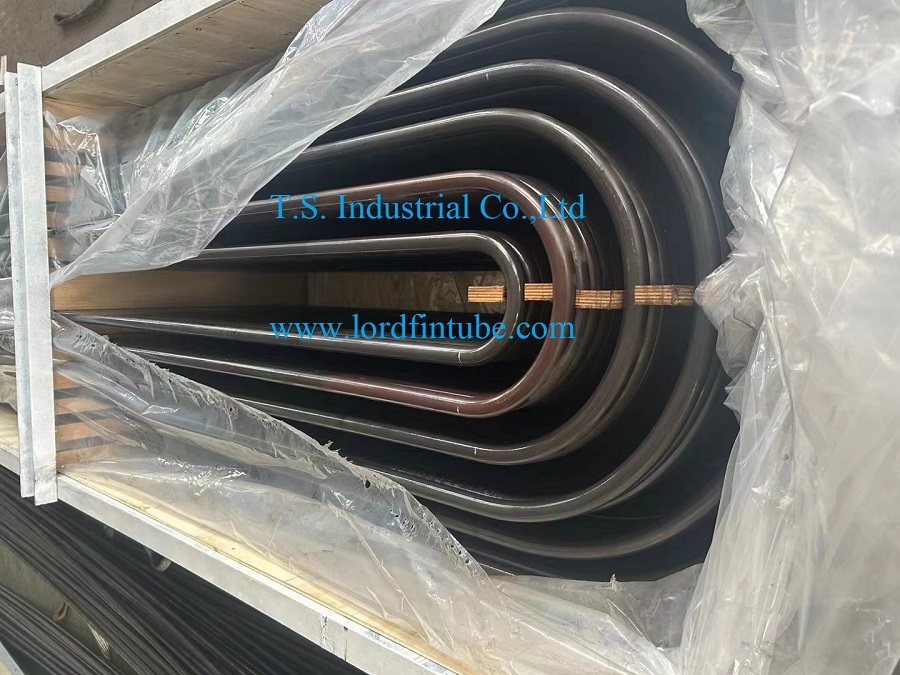

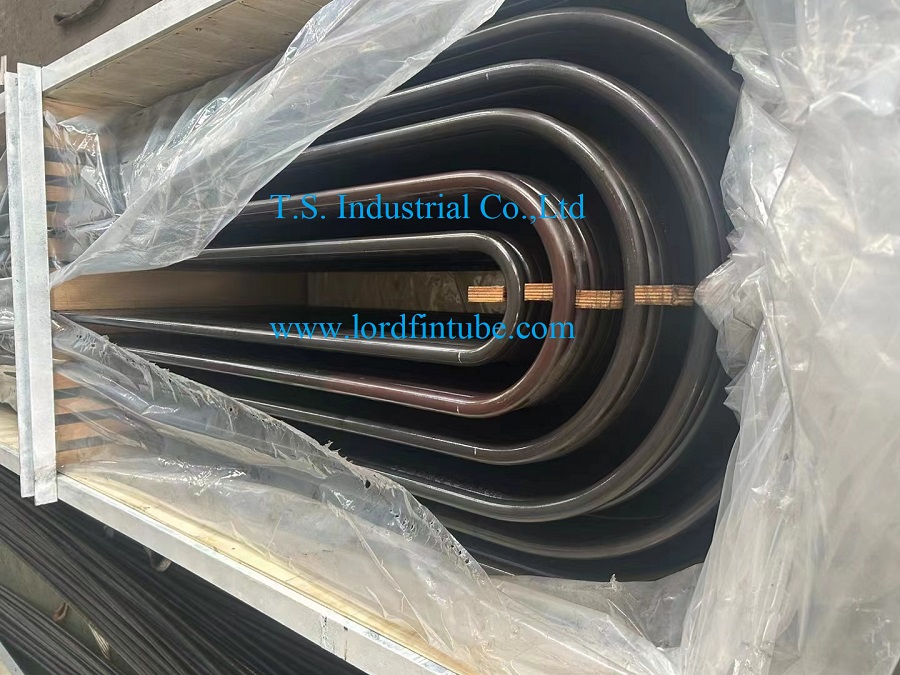

Products Description

What are U bend ASTM A214 Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes?

ASTM A214 is a standard specification for electric-resistance-welded carbon steel heat-exchanger and condenser tubes. These tubes are intended for use in boilers, heat exchangers, and condensers for various applications. The "U bend" designation refers to the shape of the tube, which has a U-shaped bend in it. This design is often used in heat exchangers where tubes need to be bent to facilitate the flow of fluids.

Common Sizes of U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes:

The common sizes of ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes can vary, and the specific dimensions depend on the requirements of the application. Typically, these tubes come in various diameters and wall thicknesses to suit different heat exchange needs. The common sizes of ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes vary, but they typically range in outer diameter from 1/2 inch to 5 inches and in wall thickness from 0.028 inch to 0.375 inch.

U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes Typical Advantages:

1. Space-Efficient Design: U bend tubes are known for their space-efficient design, making them suitable for applications with space constraints.

2. Improved Fluid Flow: The U-shaped bend can enhance the fluid flow and heat transfer efficiency within the tubes.

3. Reduced Stress: The U bend design helps reduce stress on the tubes, especially in applications with thermal cycling.

Why Use U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes?

The U bend design is particularly advantageous in heat exchanger applications where tubes need to change direction to accommodate the layout of the system. This design allows for efficient heat transfer while fitting within the space constraints of the heat exchanger.

U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes Chemical Composition:

The chemical composition of ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes typically includes elements such as carbon, manganese, phosphorus, sulfur, and silicon. The specific composition will be in accordance with the requirements of the ASTM A214 standard.

U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes Mechanical Property:

The mechanical properties of U bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes will meet the specifications outlined in the ASTM A214 standard. This includes parameters such as tensile strength, yield strength, and elongation.

How to Process U Bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes?

The process of forming U bend tubes involves bending the straight tubes into a U shape using specialized equipment. The bending process should adhere to industry standards to ensure the desired dimensions and quality. After bending, the tubes may undergo further processing steps such as heat treatment, testing, and finishing to meet the specified requirements.

U bend ASTM A214 ERW Carbon Steel Heat-Exchanger and Condenser Tubes are a specific type of heat exchanger tube designed for efficient heat transfer in various industrial applications. Their U bend configuration offers advantages in terms of heat transfer efficiency and space optimization. The chemical composition and mechanical properties are crucial for determining the suitability of these tubes for specific applications. The manufacturing process involves bending the tubes into a U shape and may include additional treatments to meet the required specifications. These tubes are designed to transfer heat efficiently in various applications, such as power generation, chemical processing, and industrial heating.

U bend ASTM A214 ERW Heat-Exchanger Tubes