What is extruded aluminum fin tube?

What is extruded aluminum fin tube? Extruded aluminum fin tubes are heat exchanger tubes made of base tube with external aluminum fins attached to their surface. The base tube can be any material.

read more

H type corten finned tube

What is H type corten finned tube? H type corten finned tube is H type finned tube and the bare tubes are Corten steel tube.H type corten finned tube is widely used in various boiler air preheater products.

read more

ASTM A105 Forged Tube Sheet

ASTM A105/ A105M is the standard specification for carbon steel forgings for piping applications. ASTM A105/ ASME SA-105 forgings cant be used for the manufacture of tubesheets.

read more

What are the components of finned tube bundle?

The heat exchange unit composed of multiple finned tubes arranged according to certain rules is called finned tube bundle. The tube bundle is the main part of the air cooler, which is composed of finned tubes, tube boxes and frames.

read more

ASTM A213 TP304 extruded finned heat pipe

ASTM A213 TP304 extruded finned heat pipe is a type of heat exchanger used in various industries for efficient heat transfer, such as in chemical processing, power generation, and oil and gas industries.

read more

What are the advantages of serrated finned tubes?

What are the advantages of serrated finned tubes? Serrated finned tubes offer several advantages over other types of finned tubes: The serrated high frequency welded spiral finned tube are not easy to form dust and scale between the fins.

read more

Evaluation of Heat Recovery Steam Generator

The combined cycle power plant consists of topping cycle,bottoming cycles and heat recovery steam generators(HRSGs) as the integral systems.The main focus of this work is to predict and analyse fluid flow behaviour in HRSG.

read more

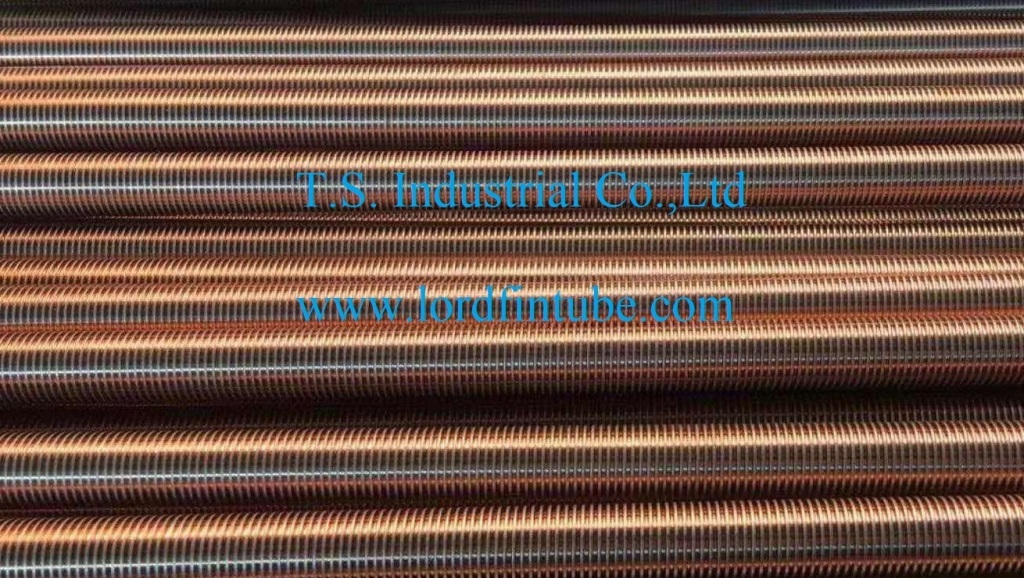

S/T Trufin in Copper-Nickel Alloys Tube

S/T Trufin in Copper-Nickel Alloys Tube is designed for boiling and condensing of hydrocarbons and other liquids. Integral helical fins on the outside of the tubes provide an increase in outside surface area.

read more

Aluminum Finned Tubes

L-Foot Tension Wound Finned Tubes;Edge Tension Wound Finned Tubes;Embedded Finned Tubes;Extruded Finned Tubes;Perforated Finned Tubes

read more

Types of Industrial Boilers

Fire Tube Type Waste Heat Recovery Boilers (WHRB), Heat Recovery Steam Generators (HRSG),Oil & Gas Fired Water Tube Boilers, Solid Fuel (Biomass & Coal) Fired Water Tube Boilers

read more

Why finned tube surface area is important?

As the name describes, the purpose of a fin tube heat exchanger is to transfer heat. But you need to know how much heat you want exchanged and that requires a certain amount of area to accomplish the heat transfer.

read more