Lord Fin Tube-High Efficiency Spiral Corrugated Titanium Tube

High Efficiency Spiral Corrugated Titanium Tube

T.S. Industrial specialized in corrugation of metallic tubes mostly applied in heat exchangers for food industry, naval & marine service, chemical plants and refrigeration. Corrugation grooves in the external and internal tube surface create a turbolence allowing a very efficient thermal exchange in comparison with traditional smooth tubes.

High Efficiency Spiral Corrugated Titanium Tube

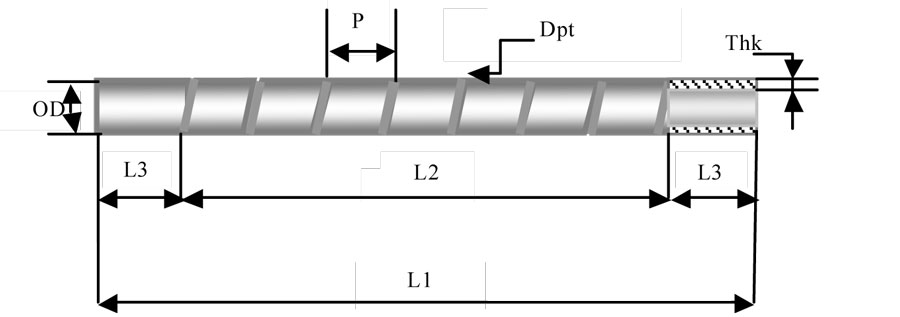

Spiral Corrugated Titanium Tube Dimension

OD = Tube external diameter

Thk = Tube wall thickness

P = Corrugation pitch

Dpt = Corrugation depth

L1 = Overall length

L2 = Corrugation length

L3 = Smooth ends length

Description of corrugated titanium tube

High efficiency spiral corrugated titanium tube is a special processing tube made through strengthening treatment of inner and outer surface of tubes with different material, to achieve the purpose of high efficient heat transfer in a special environment.

High Efficiency Spiral Corrugate Titanium Tube Application

Titanium heat exchangers, condensers, evaporators related to electric power, chemical industry, seawater utilization and marine engineering, aerospace, metallurgy, medicine, food and other industries.Industrial fluids titanium pipes, corrosion-resistant pipes and brackets for industrial equipment and pressure vessels.

High Efficiency Spiral Corrugate Titanium Tube Characteristics

* The heat transfer area between the fluid and the wall is increased, and the total heat transfer of the tube is increased

* Enhancing the fluid turbulence * It improves the contact efficiency between fluid and wall

* Destroy the development of fluid thermal boundary layer and enhance the heat transfer capacity of the tube

* The resistance of vapor molecules diffusing to the surface of the liquid film is reduced

* Improving the hydrophilicity * Good hydrophilicity can reduce the thickness of water film and increase the heat transfer area

* The contact market between the fluid and the wall can be increased within a certain range. Which has a good effect of enhancing heat transfer Effectiveness Rib effect coefficient: 180% ~ 300%

Application of Spiral Corrugated Titanium Tube:

1. Thin wall titanium welded pipes for heat exchangers, condensers, and evaporators,

2. Titanium welded industrial fluid pipes, corrosion-resistant pipes

3. Support pipes for various industrial equipment and pressure vessels are used in the power industry, the chemical industry, seawater utilization and marine engineering, aerospace, metallurgy, medicine, food, and other industries.

Links to Lord Fin Tube: